Installation and operating instructions profi-air 250/360 flex

4

1 General information

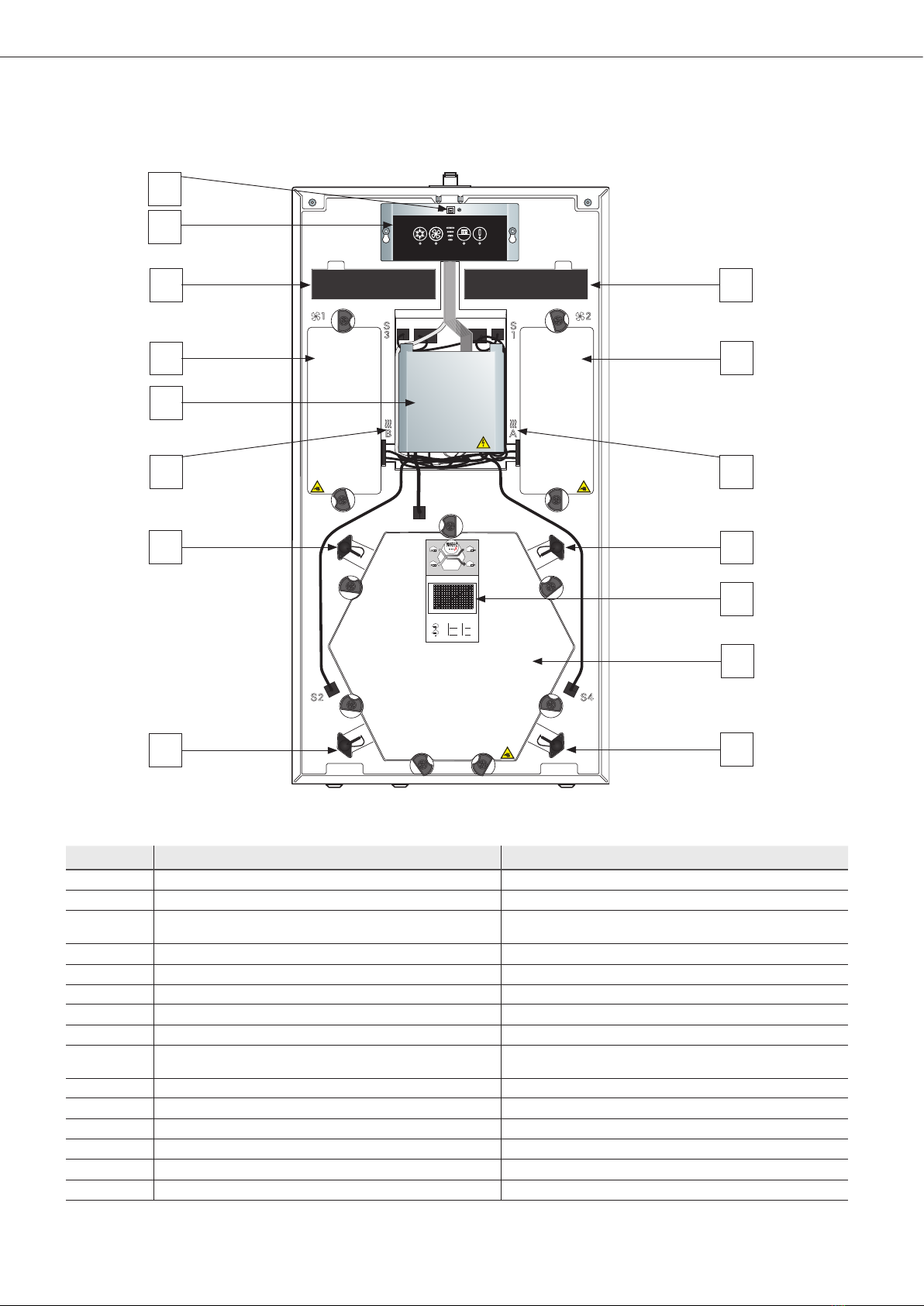

Ventilation units from the FRÄNKISCHE profi-air product

range constitute an important part of a heat recovery ventila-

tion system. They bring the required volume of supply air to

and take extract air from rooms.

With the help of an integrated plastic cross-flow heat exchang-

er, these ventilation units provide high heat recovery eciency.

These installation and operating instructions are intended to

help you install a fully functional profi-air 250/360 flex ventila-

tion unit and properly operate it. We therefore recommend

that you read these instructions carefully before you carry out

Even if the fresh air temperature is around the freezing point,

the supply air is heated virtually to the room temperature.

All profi-air ventilation units are fitted with fully automatic sum-

mer bypass flaps in order to prevent undesired heating of the

fresh air during transitional seasons.

1.1 Introduction

any activities on the unit or make any settings on the unit.

These installation and operating instructions can also serve as

a reference for service and maintenance work and guarantee

smooth and ecient operation.

If used as intended, the unit is safe and reliable to operate.

The construction and design are state of the art and comply

with all relevant DIN / VDE regulations and safety provisions.

All safety regulations, warnings and notes of these installation

1.2 Safety

and operating instructions have to be observed; non-obser-

vance might result in personal injury and/or damage to profi-air

250/360 flex.

1.2.1 Safety regulations

nInstallation, connection, commissioning as well as maintenance of profi-air 250/360 flex may be performed by authorised

and qualified personnel only (with the exception of filter replacements).

nInstallation of profi-air 250/360 flex is to be carried out according to the applicable local construction, safety and installation

regulations.

nNon-authorised changes or modifications of profi-air 250/360 flex are not allowed.

nInstructions regarding regular filter replacement are to be strictly adhered to.

nKeep these installation and operating instructions near the ventilation unit during the entire life of profi-air 250/360 flex.

1.2.2 Safety equipment and measures

nThe profi-air 250/360 flex unit cannot be opened without tools.

nMake sure that the fans cannot be touched with hands as long as the system is connected to the power grid.

nIn case of maintenance, the device may therefore be opened in the “dead” state only, and profi-air 250/360 flex may only be

operated with the installed duct network.