7.2.3 Shortening pipes

7.2.4 Shaft connections to AquaTracControl

7.2.5 Embedding and backfilling of pipes and shafts

The provisions of DIN EN 1610 and

DWA-A 139 generally apply. Carry out

backfilling according to design specifica-

tions. It includes side filling, covering

within the embedding area, and main

backfilling. Create the embedding of the

pipe in the embedding area with stone-

less, compactable material. Backfill the

bedding material evenly on both sides of

the pipe above the pipe crown in layers

of approx. 15cm, and compact using

light compaction equipment only or,

if required, even by hand. Further filling

(as of approx. 15cm above the pipe

crown) must be made in layers with con-

stant compaction of the filling material.

Mechanical compaction of main backfill-

ing with light to medium equipment

directly above the pipe should only be

performed starting from a minimum

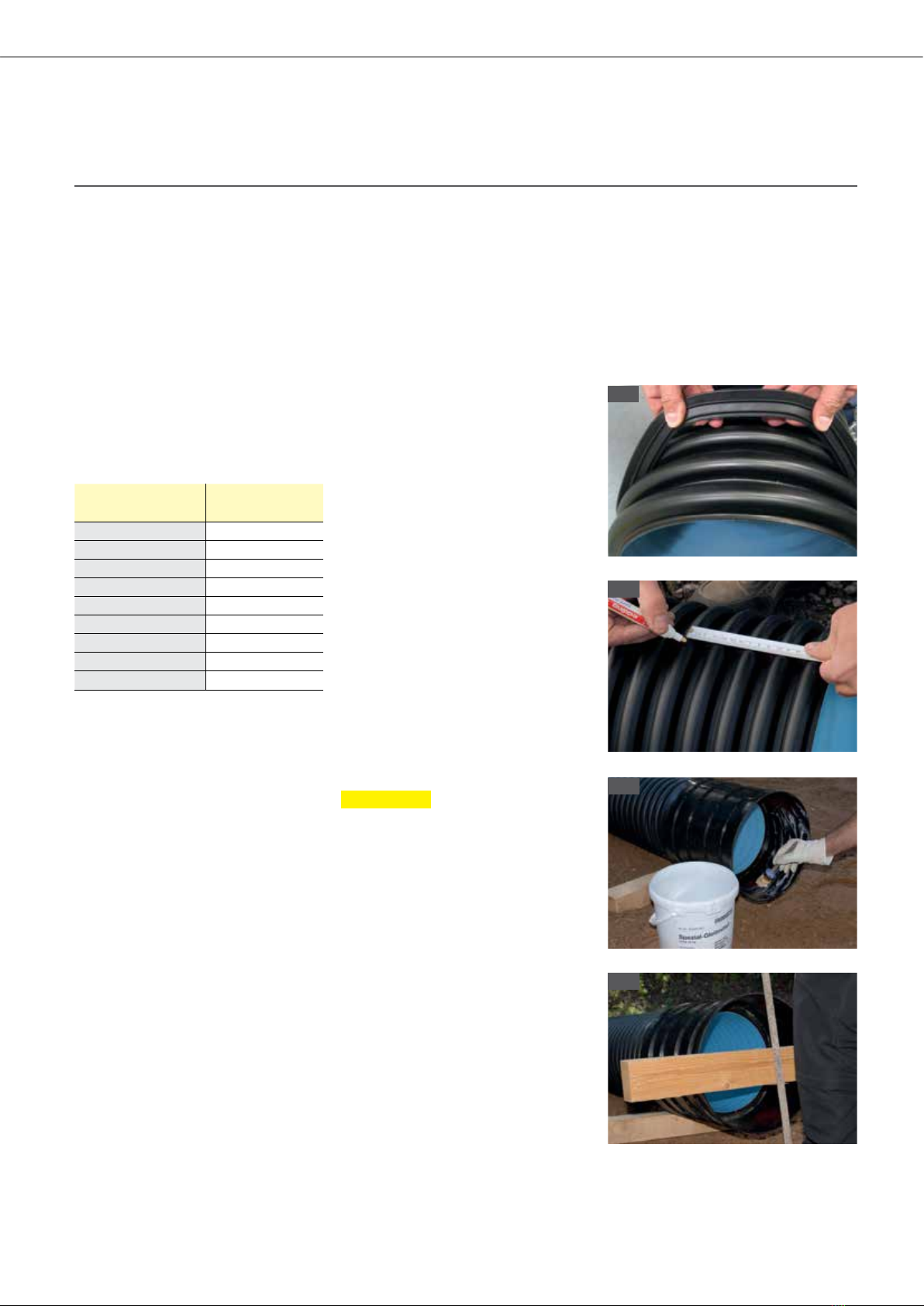

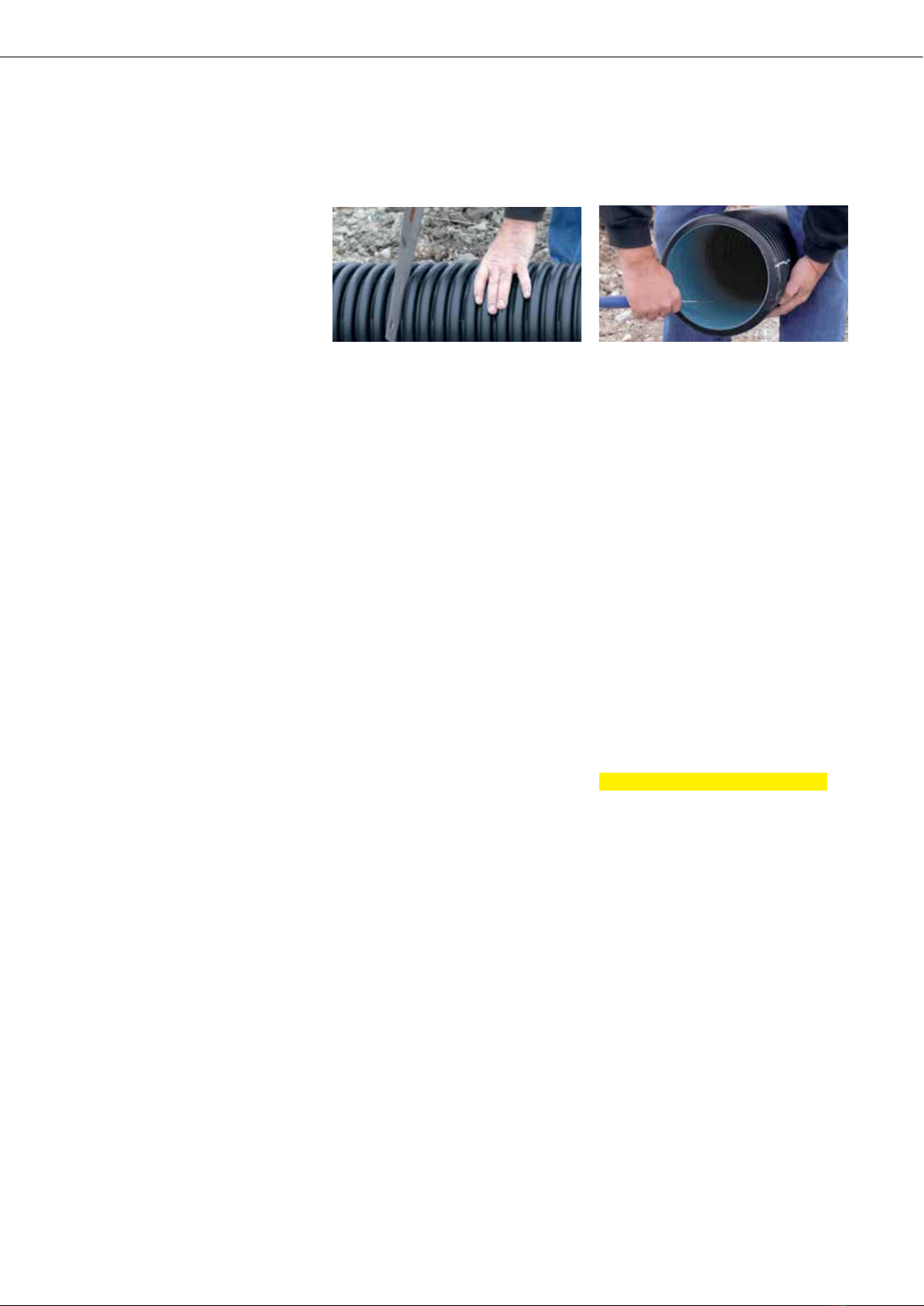

Cut the pipes to length in the middle of

the corrugation trough and align upright

to the pipe axis using a fine-toothed saw

or other appropriate tools. Remove

edges and irregularities on the cutting

surfaces with a grater, file or another

suitable tool.

Proceed as follows:

1. Clean the insertion area of the pipe

and the insides of the shaft connec-

tions at AquaTracControl from dirt

using a rag or similar.

2. Insert the profile sealing ring continu-

ously and without overexpanding indi-

vidual spots into the first complete

corrugation trough of the AquaPipe

pipe at the spigot (when cutting pipes,

make sure that cuts are in the middle

of the corrugation trough and there is

no damage to the corrugation edge).

3. Evenly apply a sucient amount of

lubricant to the profile sealing ring

and the inside of the shaft connec-

tion. Do not use oils and greases.

4. Right before installation, check the

shaft connection and pipe ends

again for foreign objects and remove

if necessary. Please pay particular

attention to gravel, sand or crushed

stones which could have entered the

insertion area during work at the pipe

and shaft and/or stick to lubricated

sections.

5. Insert pipes to the limit stop. Protect

the pipe section using a square timber

and distribute installation forces

equally during installation.

Please observe the following

The use of heavy construction gear

and vehicles and storing excavated

material in the area over covered

pipes are not admissible unless

relevant load conditions have been

considered in the static calculation.

This holds true particularly for pipe

systems with low depths of cover.

7.2.6 Placing the extension pipe

The extension pipe must be inserted into

the upper area of the shaft base body.

For watertight systems, place the profile

7 Installation

thickness of 30cm above the pipe

crown. Use heavy compaction equip-

ment only starting from a depth of cover

of 1.0m above the pipe crown. Choose

compaction equipment, the number of

compaction runs and the thickness of

layers subject to compaction depending

on the material to be compacted and the

pipe system to be installed. To avoid

load concentration on the pipe, consist-

ent compaction throughout the entire

embedding area must be ensured. In

addition, the pipes must not come in

contact with compaction equipment.

Preferably secure the pipes from lateral

and vertical forces during installation.

Embed the shaft and compact the

bedding material analogously to the

pipe. Insert the extension pipe for this

process (see Section 7.2.6).

sealing ring into the first corrugation

trough of the extension pipe. Evenly

apply a sucient amount of lubricant to

the profile sealing ring and the inside

of the insertion area. Do not use oils

and greases. Afterwards, insert the

IM AquaPipe

6