2

13. Disconnecting, bypassing, tampering with or otherwise interfering with safety valves,

high limit thermostats, pressure switches or other safety or control devices may

cause serious injury and/or damage to the appliance.

14.If the steam pressure gauge reads more than 1.5Bar do not use the machine. Isolate

the machine from the mains power supply and mains water supply. Contact Fracino

or a Fracino approved service centre for advice, inspection and repair.

15.If the water/pump pressure gauge reads more than 12Bar do not use the machine.

Isolate the machine from the mains power supply and mains water supply. Contact

Fracino or a Fracino approved service centre for advice, inspection and repair.

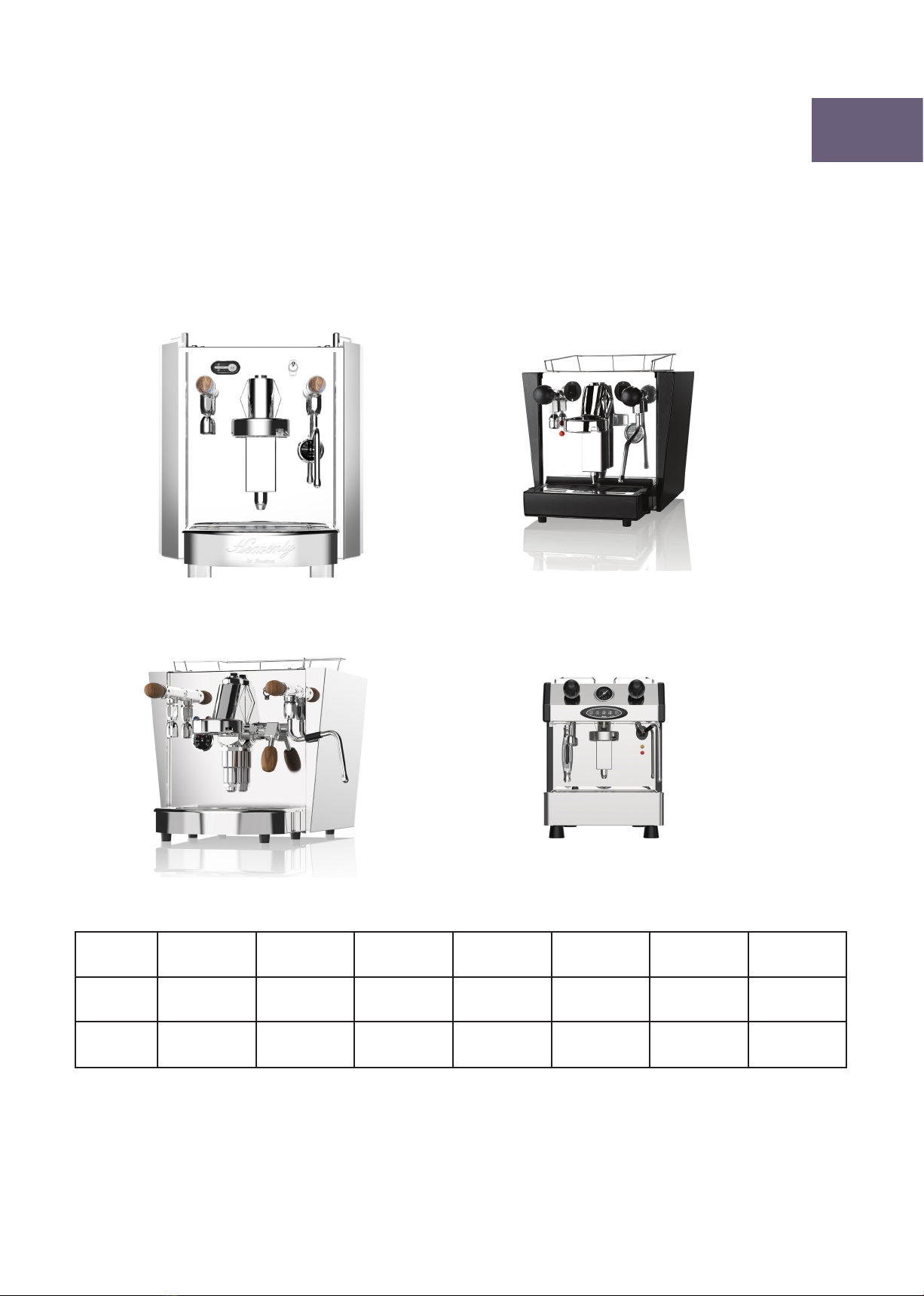

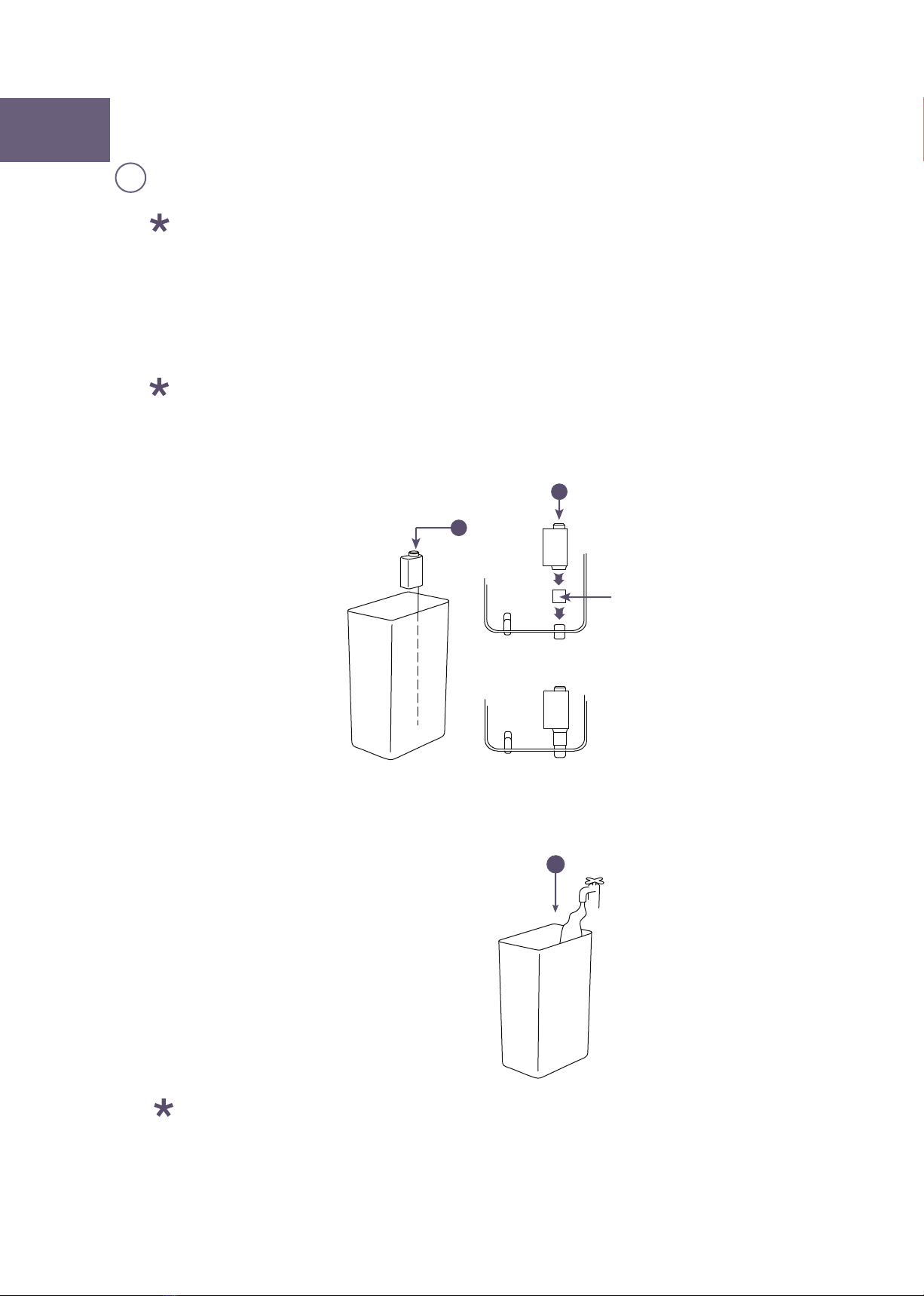

16.When using the Heavenly, Cherub, Classico and Little Gem models, ensure the

water tank has sucient fresh cold water in it. Do not run the machine without water

in the tank as doing so will damage the pump.

17.Machines contain high voltage parts. At no time should body panels be removed

while the machine is switched on.

18.Do not operate the machine without water in the tank, doing so may cause damage

to the machine.

19.Ensure whoever is operating the appliance is fully conversant with its operation

and aware of dangers involved in incorrect operation and cleaning, especially the

dangers of burns or scalds from hot water, steam and from hot surfaces of the

working area.

20.Fully isolate the gas supply at the gas bottle when the machine is not in use.

21.Clearance around the appliance must be:

Ceiling/Shelf: 600mm Rear: 75mm Sides: 75mm

22.If using an inverter, ensure the selector switch is on ‘GAS’ otherwise the unit will

overload.

23.The following procedure can only be done by qualied personnel. Adjustments can

only be made to increase or decrease steam pressure or to regulate the low ame

height.

24.Check the Sight Glass to ensure there is water in the boiler. The water lever should

be at least half way up the Sight Glass.

25.By their nature lever machine can be dangerous if used incorrectly. Ensure you have

read and understood all instructions before using the Retro Lever machine. If in

doubt contact Fracino for advice.

26.The appliance must not be cleaned with a water jet, or located in an area where a

water jet could be used.