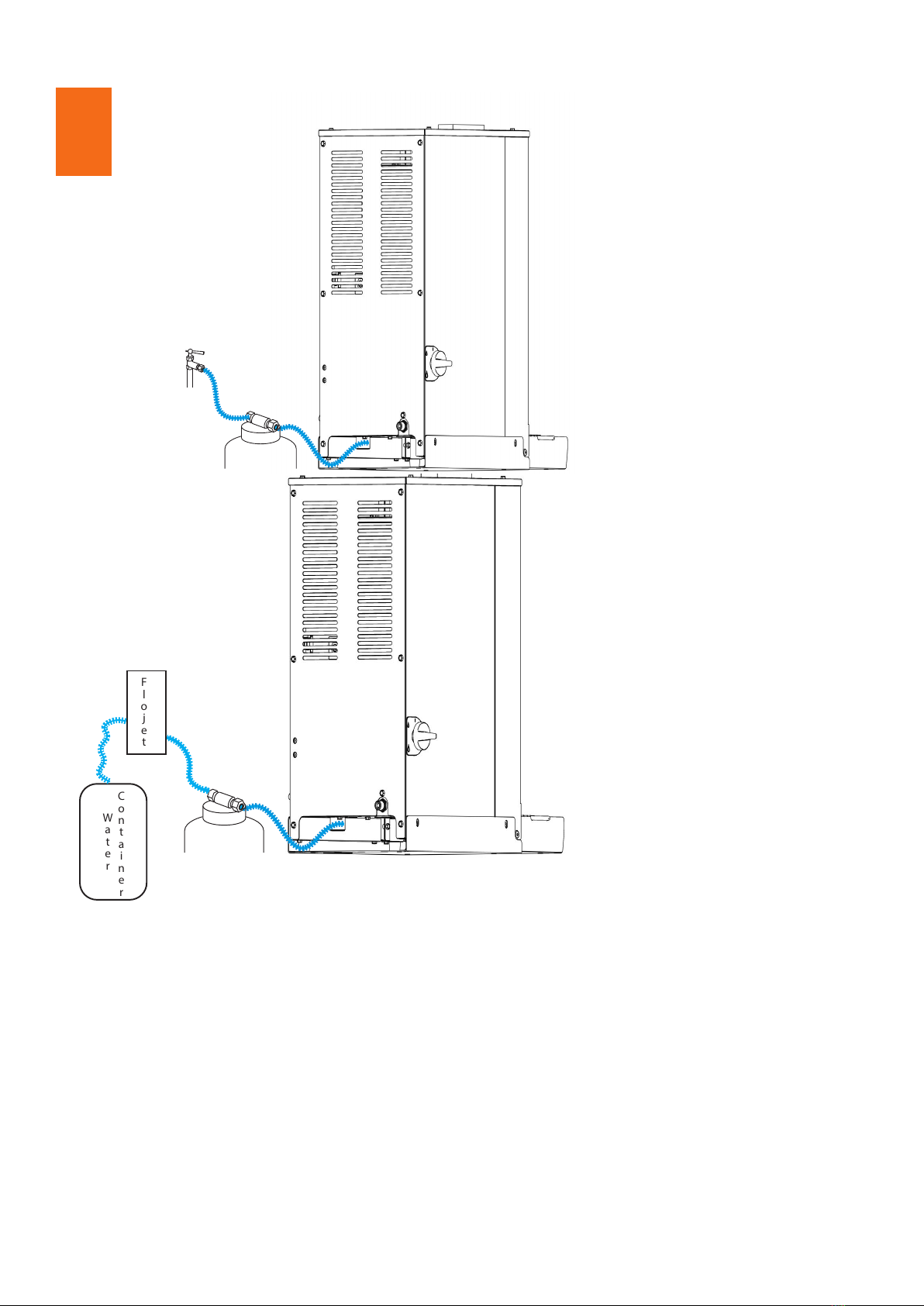

LPG Mobile installation

Connect 1/2” gas hose to the gas inlet tting on the rear of the appliance ensuring it

is tight. Attach an isolation valve to the other end of the gas hose. Attach the isolation

valve to 8mm ridged mounted copper tube at a length suitable for installation. Ensure

that the pipework is in a location where it CAN NOT be easily damaged.

The copper tube is connected to a bulkhead tting that has a Fulham nozzle protruding,

x the required high-pressure hose to the Fulham nozzle with a jubilee clip ensuring it

securely xed. The other end of the high-pressure hose is connected to an appropriate

gas regulator that complies with all regulations in force. The gas regulator is then

connected to the relevant gas supply.

NOTE: All gas supply hoses or tubes shall comply with the national requirements in

force and shall be examined periodically and replaced if necessary.

NOTE: It is recommended that a gas sealant is used on all joints.

NOTE: Gas installations should only be carried out by a qualied engineer and in

accordance to EN1717.

Australia / New Zealand ULPG

How to connect gas supply

This appliance is designed to be run on Universal Liquid Petroleum Gas (ULPG) via a

xed pressure regulator set at 2.75kPa with a Nominal Gas Consumption of 7.92MJ/h,

additional information can be found on the data plate attached to the rear of the appli-

ance.

All lines must be purged before ignition. A pressure test point complying with AS 5061

is built into the connection pipe between the gas isolation valve and solenoid, located

behind the rear panel of the appliance

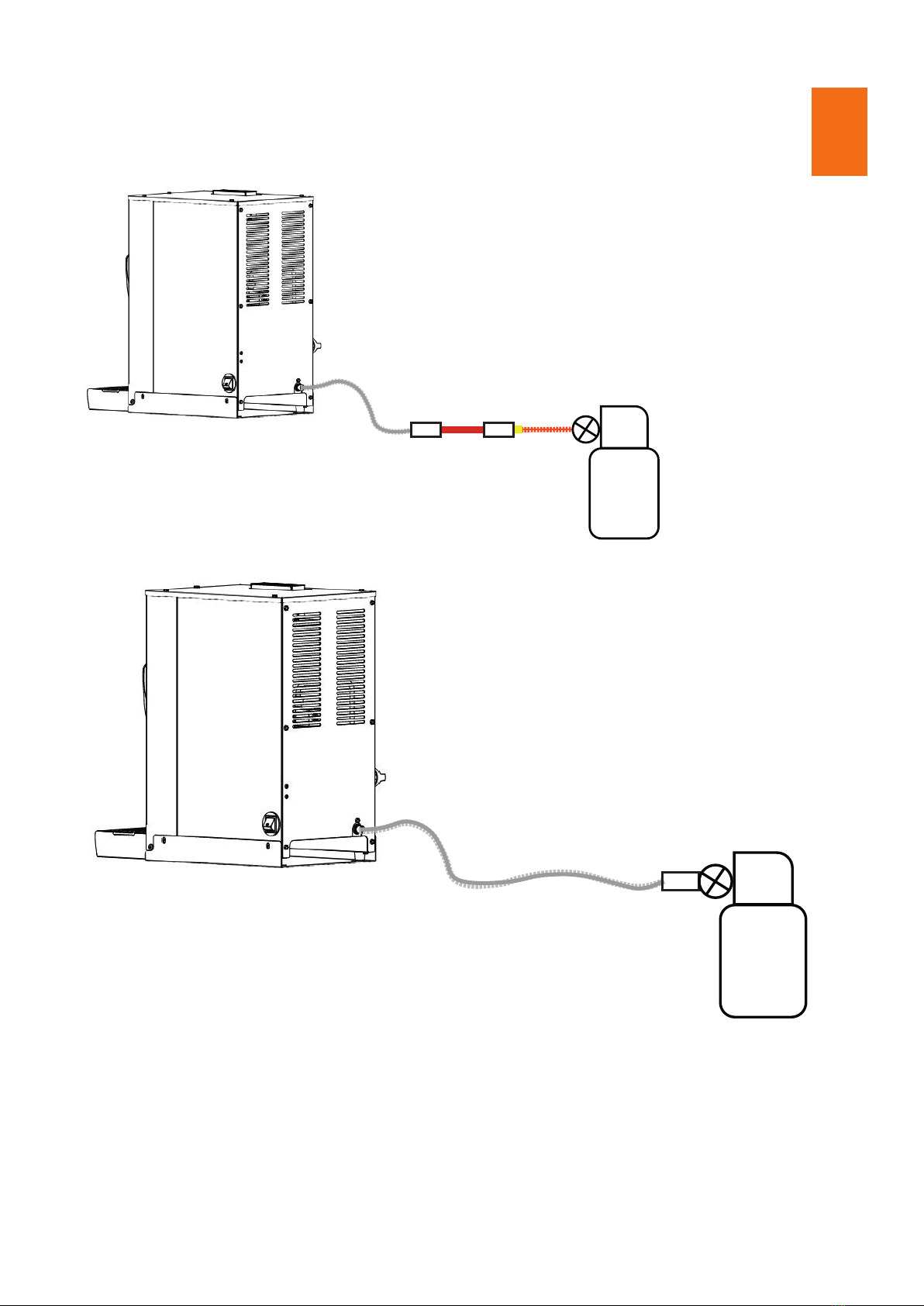

Static LPG installation

Connect the approved 2.75kPa xed pressure regulator to the 1/2” gas inlet tting at

the rear of the appliance, ensuring it is tight, then connect 1/2” gas hose to the gas

xed gas regulator also ensuring it is tight. Attach an isolation valve to the other end of

the gas hose which is then connected to a suitable ULPG bottle.

LPG Mobile installation

Connect the approved 2.75kPa xed pressure regulator to the 1/2” gas inlet tting at

the rear of the appliance, ensuring it is tight, then connect 1/2” gas hose to the gas

xed gas regulator also ensuring it is tight.

Attach an isolation valve to the other end of the gas hose. Attach the isolation valve to

8mm ridged mounted copper tube at a length suitable for installation, ensure that the

pipework is in a location where is CAN NOT be easily damaged.

The copper tube is connected to a bulkhead tting that has a Fulham nozzle protruding,

x the required high-pressure hose to the Fulham nozzle with a jubilee clip ensuring it

securely xed.