to the right. To cut shallower, turn the stop to the left. The stop has threaded holes in several

positions. Make another cut on the key and measure until the machine is cutting to the proper depth.

SPACING ADJUSTMENT

To adjust the spacing on the KX-1, insert an original key into the vise. Turn the spacing cam to the

first position and set the depth cam to the proper depth of the first cut on the original key. Use the

feed handle to move the key into the cutter and determine if the carriage needs to be moved to the left

or the right.

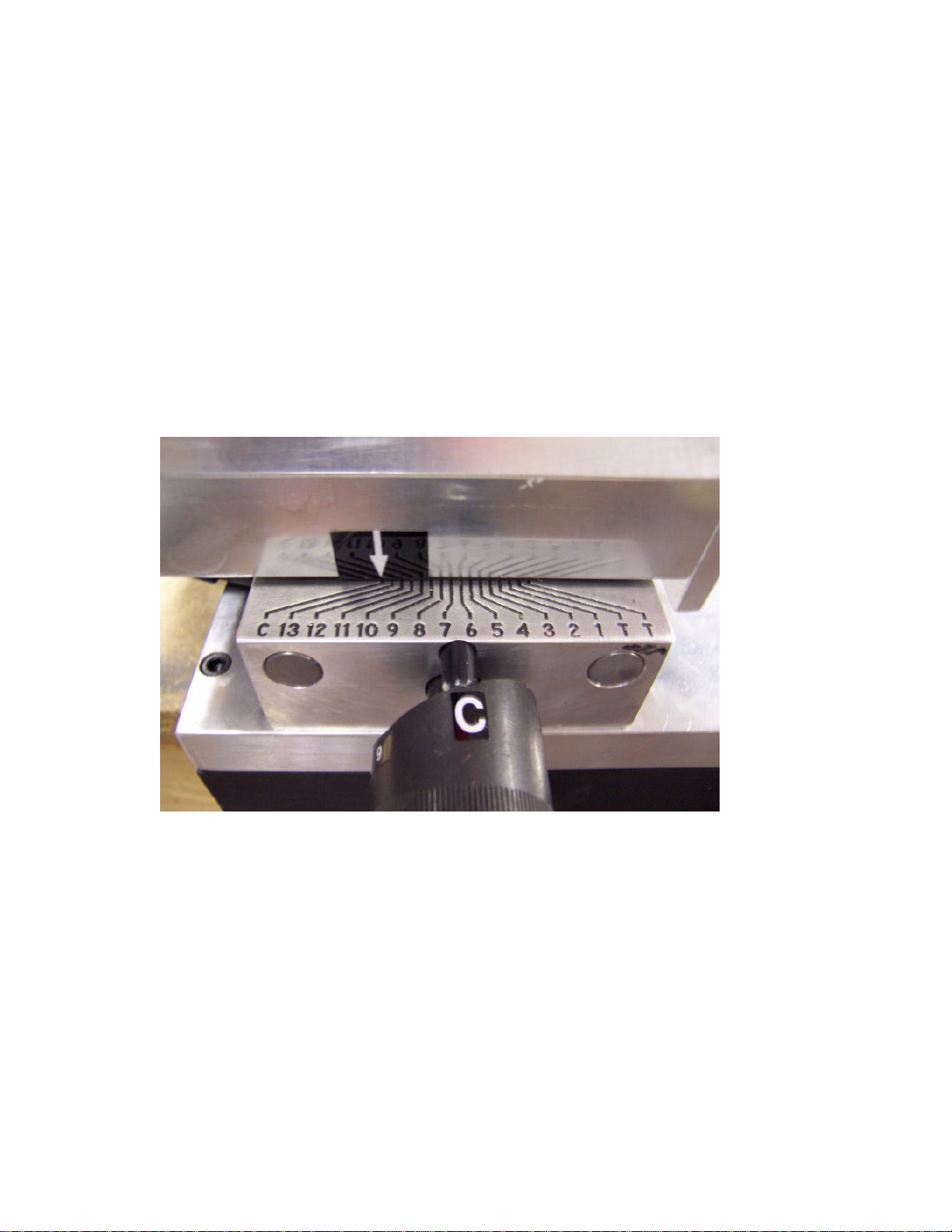

Slide the carriage to the right as far as it

will go (by hand). With the carriage in

this position, a setscrew will be

accessible thru the small hole located

just behind the key vise (see Figure 3).

Using the 3/32” Allen wrench, loosen

the setscrew. Next, using the 1/8” Allen

wrench, remove the setscrew located on

the left side of the carriage (See figure

3). Insert a flat screwdriver into this

hole (about 3 inches) and turn the screw

clockwise to move the vise to the right

of the cutter. Turn the screwdriver

counterclockwise to move the vise to

the left of the cutter. Once you have set the proper spacing, remove the screwdriver from the carriage

and replace the Allen screw. Re-tighten the setscrew by pushing the carriage all the way to the right

and inserting the 3/32” Allen wrench into the opening. Release pressure on the carriage.

TILTING SPINDLE ASSEMBLY

Your KX-1 has the ability to cut Medeco Commercial, Bi-Axial, and Emhart keys. To make angled

cuts, release the pressure on the spindle by loosening the lock rod located on top of the machine (the

lock rods are shipped inside the drawer, if you are not cutting Medeco you may choose not to install

them). Tilt the spindle by lowering or raising the tiltingspindle rod until it comes to a positive stop.

Re-tighten the tilting spindle lock rod and make your cuts for that angle. To save time, make all of the

center cuts first, then your left angle cuts, then the right angle. To re-center the spindle, loosen the tilt

spindle lock rod and move the tilt spindle rod to the center position, where you will feel a detent, and

tighten the tilting spindle lock rod.

MAINTENANCE

Very little maintenance is required on the KX-1. A slight touch of regular automotive grease on the

rod that contacts the space and depth cam will assure smooth operation of the cams. Teflon spray can

be used on the slide rods to keep them moving freely. The KX-1 uses sealed ball bearings in the

motor and spindle, which require no maintenance whatsoever.

Figure 3: Location of setscrews

Figure 3: Location of setscrews