HCMF Service Manual

For Technical Support, Call 800-537-2653. Page 4 Doc. No. 19005309 - Copyright 2012 Franke, Inc.

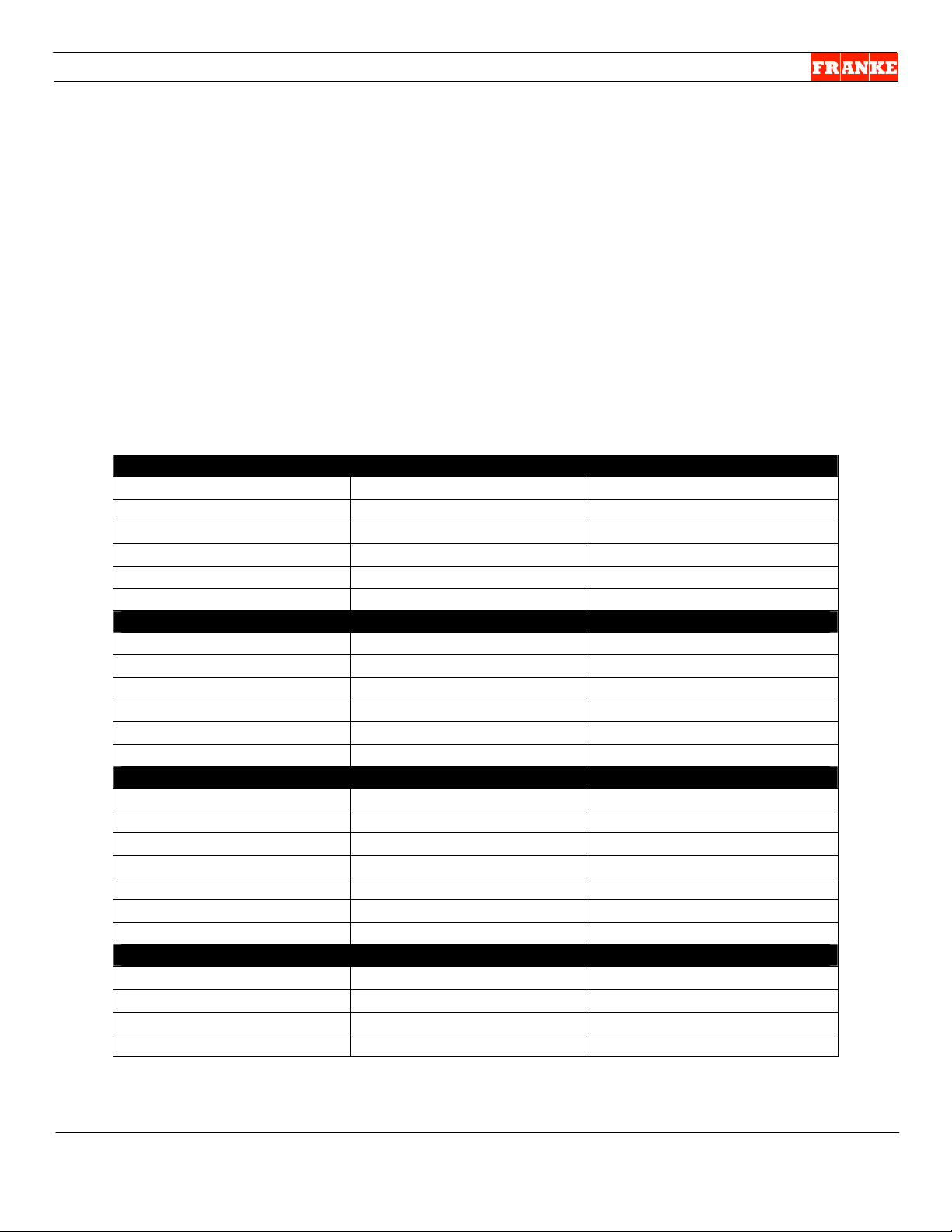

Section 2 – Control Settings & Operating Parameters:

Control Settings & Operating Characteristics (For Troubleshooting)

Danfoss Temperature Controller For More Information

Temperature Range Adjustable

See Section 10 on page 19 to adjust

temperature

Coldest Set Point -30 degrees F

Normal Cut Out (Set Point) - 4 degrees F

Differential 2 degrees F

Normal Cut In - 2 degrees F

Warmest Set Point +30 degrees F

Compressor Protection Fixed

Minimum On Time from Start to Start 2 minutes

Fail Safe Mode (if sensor fails) Fixed

Faulty Probe On Time 4 minutes

Error Off Time 2 minutes

Defrost Settings Fixed

Termination Temperature 60 degrees F

Maximum Time Allowed 60 minutes

Drip Time (heat off) 1 minute

Defrost Based On Compressor On Time Fixed

Time Between Defrosts 3 hours

Fan Settings Fixed

During Defrost Off

Start Delay After Defrost 4 minutes

Fan Duty Cycle – ON 40 seconds

Fan Duty Cycle - OFF 90 seconds

Display Features: Adjustments

Select degrees F or C? No NOTE: Contact Franke for degrees C

Adjust temperature from display? Yes See Section 10 on page 19 to adjust

temperature or initiate manual defrost

Initiate Defrost from display? Yes

Display during Defrost Cycle: dEF

dEF shown for maximum of 30

minutes after defrost.

Normal Operating Pressures Normal Operating Amps

High Side (85 air to condenser) 235 PSIG HCMF-30 8 – 9 Amps (4.8A Defrost)

Low Side (-5 air into coil) 13 PSIG HCMF-18 5 – 6 Amps (3.8 Defrost)

High Pressure Safety Rated Operating Amps

Cut Out Setting 460 PSIG HCMF-30 10 Amps

Differential 30 PSIG HCMF-18 7.3 Amps

Defrost High Limit Safety Operating Voltage

Cut Out Setting 70 degrees F HCMF-30 120V

Differential 15 degrees F HCMF-18 120V

R-404A 18 ounces 16 ounces