207 / 2011

Last revised:Technical modifications excepted! en

Read these instructions through carefully and keep them safe for future reference.

Copyright for these User Instructions remains the property of Franke Foodservice Systems GmbH. These User Instructions are intended to be used

only by those operating the equipment and qualified personnel. They contain instructions, pictures and diagrams, which, in their entirety or in part,

must not be copied, circulated, or be used for competition purposes without authorisation or disclosed to others. Any infringement could have criminal

consequences.

TABLE OF CONTENTS

Environmentally friendly coolant ..............................................................................................................................................3

1 Safety notes ................................................................................................................................................................3

1.1 General notes ...............................................................................................................................................................4

1.2 Intended use.................................................................................................................................................................4

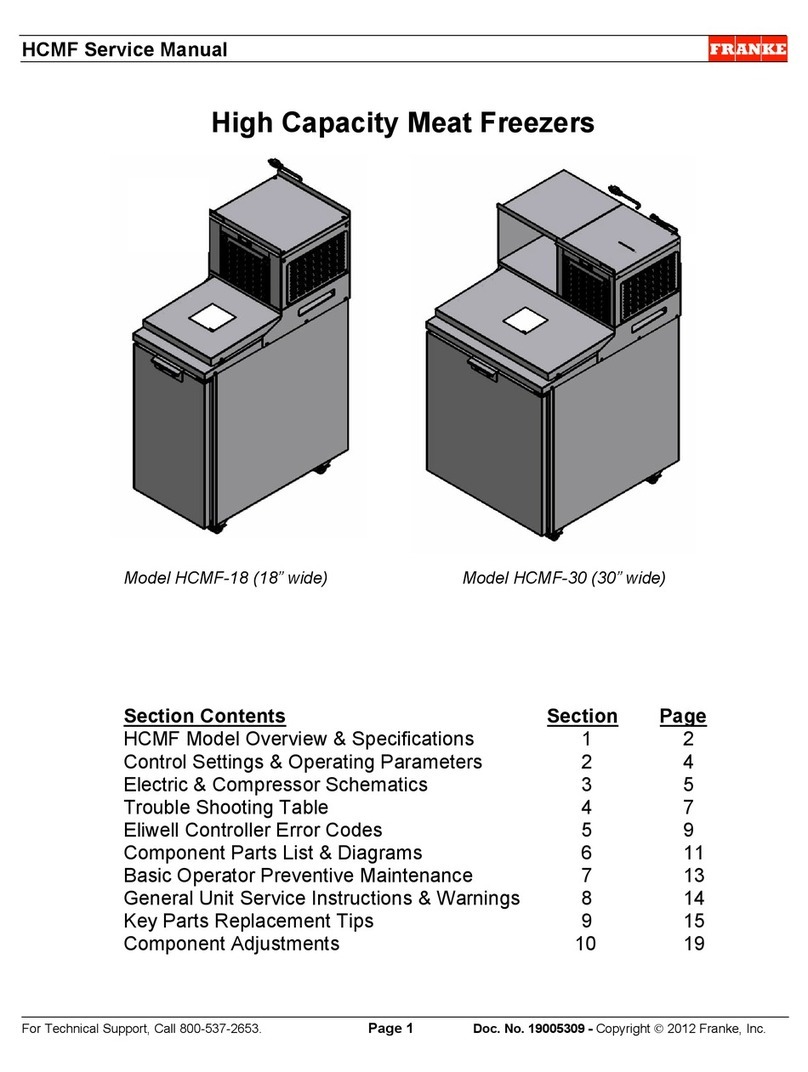

2 General Description......................................................................................................................................................4

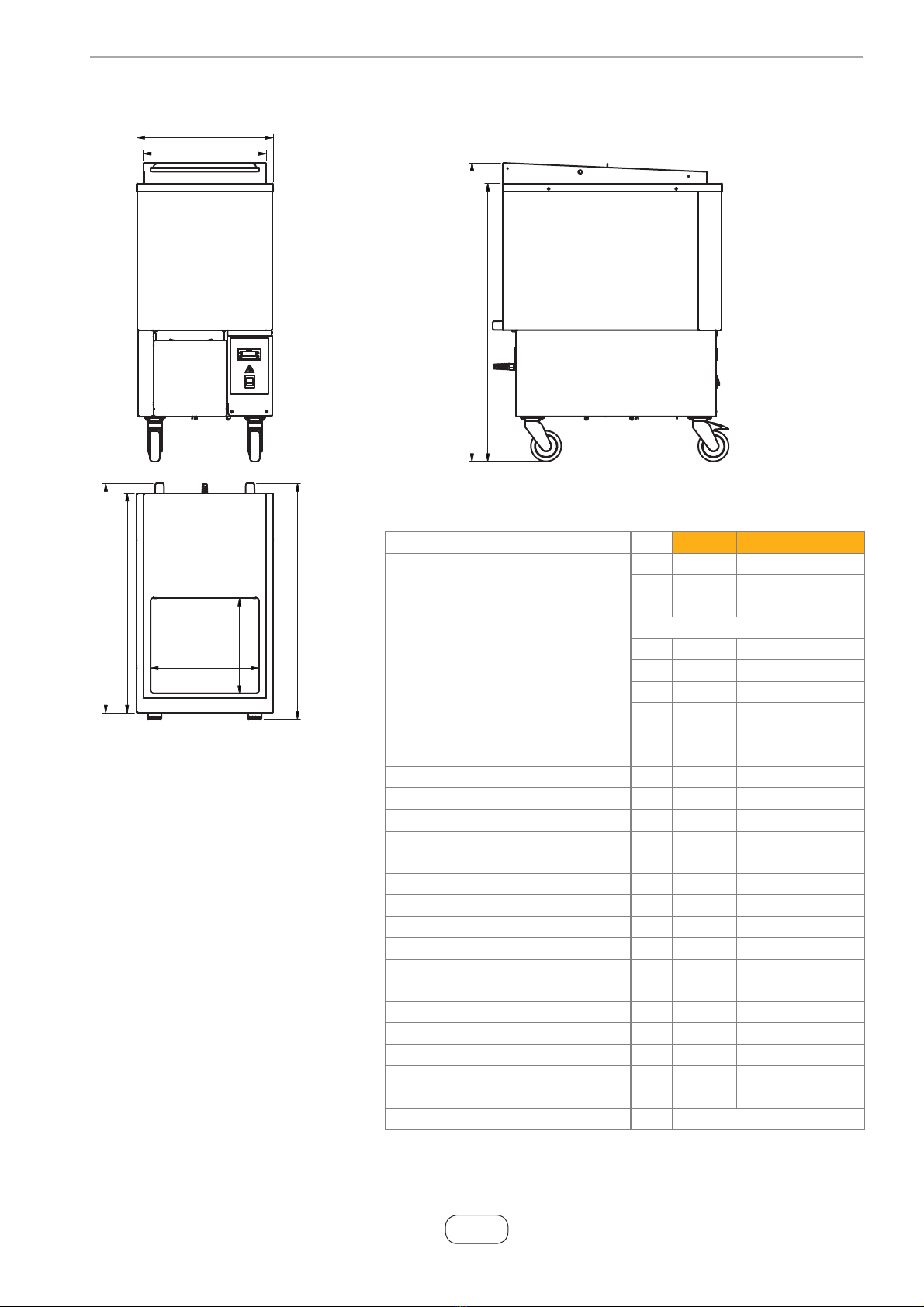

3 Technical Data and Installation .....................................................................................................................................5

3.1 Electrical connection ....................................................................................................................................................6

5 Instructions for the user................................................................................................................................................ 7

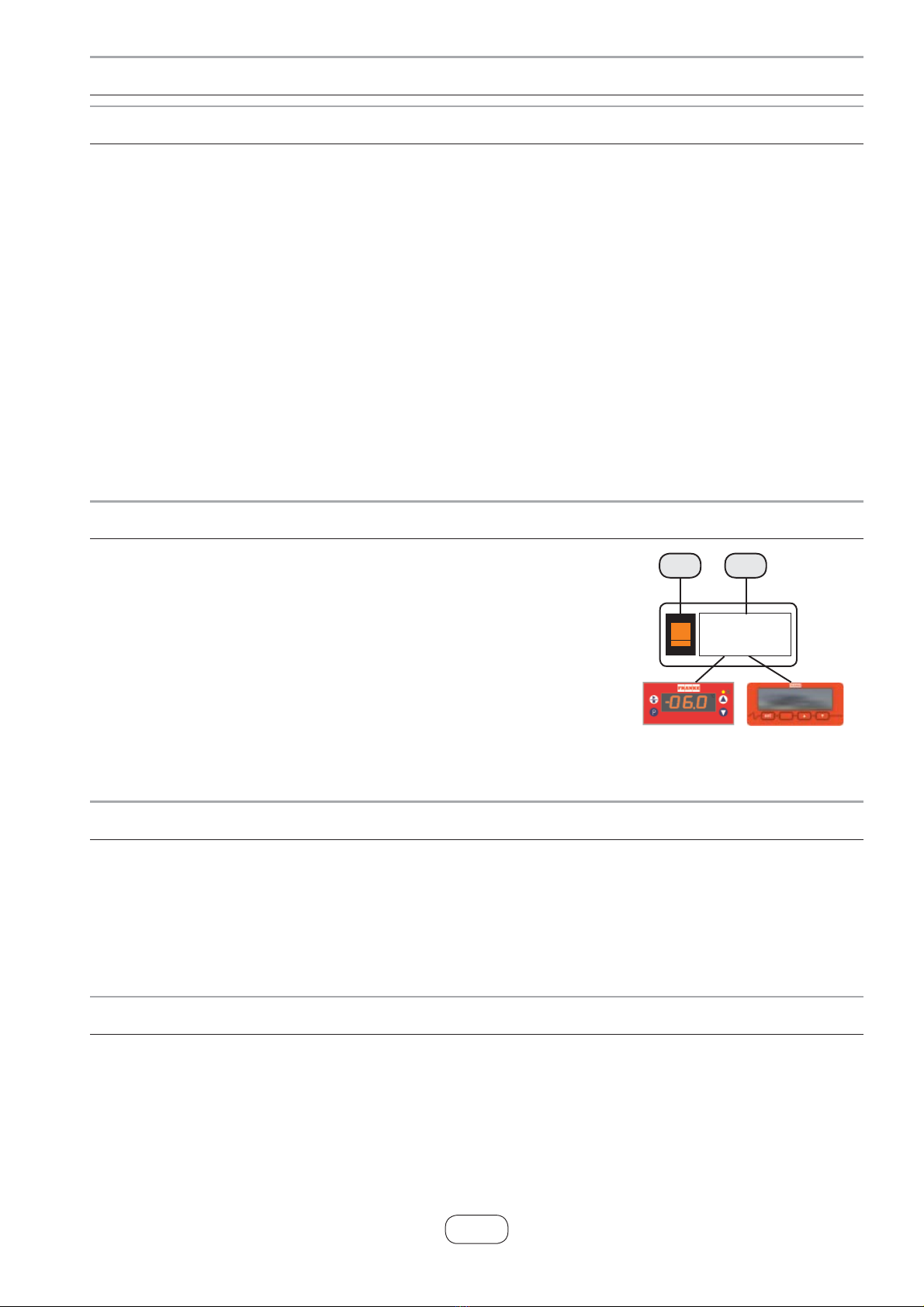

5.1 Operating instructions .................................................................................................................................................. 7

5.2 Operating panel ............................................................................................................................................................ 7

5.3 Commissioning/Switching on ....................................................................................................................................... 7

5.4 Switching off................................................................................................................................................................. 7

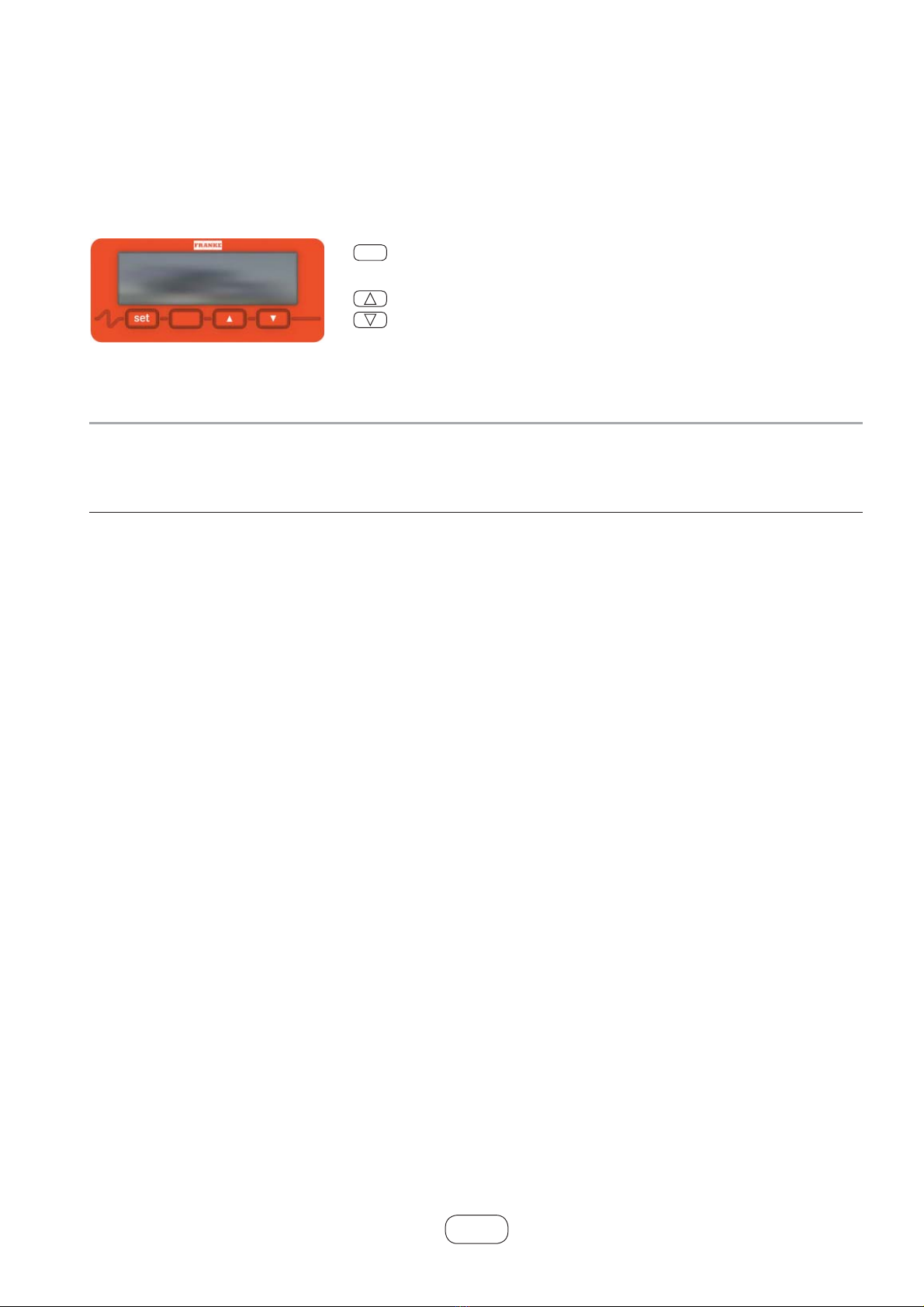

5.5 Operation of the temperature controller........................................................................................................................8

6 Cleaning and Maintenance...........................................................................................................................................10

6.1 Regular cleaning ..........................................................................................................................................................10

6.2 Long periods of non-operation..................................................................................................................................... 11

6.3 Customer service for the electronic components.........................................................................................................12

6.4 Customer service for the refrigeration system..............................................................................................................12

8 Spare parts..................................................................................................................................................................13

9 Dismantling, disposal...................................................................................................................................................14

10 Electrical diagram........................................................................................................................................................15

11 Declaration of Conformity............................................................................................................................................ 17