4

INSTALLATION TIPS

• Wrap all threaded male pipe ends and ttings with

PTFE tape. This will ensure a good seal around all

pipe connections.

• PVC Pipe Connections: Use PVC pipe primer on

all glue joints before applying PVC cement. After

applying PVC cement to both surfaces to be

glued, connect pipe and tting, turn pipe one-

quarter turn and hold for 30 seconds. This will

ensure a positive cementing of all joints.

INSTALLATION

LOCATION OF PUMP

Decide on an area for the pump installation that

is suitable based on the enclosure rating of the

electric pump motor. All Turf Boss pumps are UL778

approved and will be marked “ACCEPTABLE FOR

OUTDOOR or INDOOR USE.”

• INDOOR PUMP INSTALLATION OPTION:

Choose a clean, well-ventilated, weatherproof location

that affords protection from freezing, ooding, and

excessive heat. In addition, it should provide access

for servicing and allow convenient draining of the

pump and service pipes. A prepared foundation is not

essential, provided the surface is hard and level. It

can be located in the basement or utility room of your

house, at the well or between the point of use and

the well.

• OUTDOOR PUMP INSTALLATION OPTION:

When installing outside of the house, the pump should

be protected by a pump house with auxiliary heat to

prevent possible freezing.

Choose a clean location best suited for the water

system. A prepared foundation is not essential,

provided the surface is hard and level. It should provide

access for servicing and allow convenient draining of

the pump and service pipes. When installing outside

of the house, the pump and piping system must

be drained completely of water to prevent possible

freezing when weather dictates.

Decide how to seal the well from surface contamination

as required by local authorities. The most common

device for this purpose is the SANITARY WELL SEAL.

If the pipes from the well have to be kept below the

frost line, either bury the wellhead or use a PITLESS

ADAPTER that leaves the wellhead exposed for

servicing while providing sealed openings in the well

casing below the frost line.

Following are three well and water source

applications for the Turf Boss sprinkler pump.

Wells may differ slightly but the application is

essentially the same.

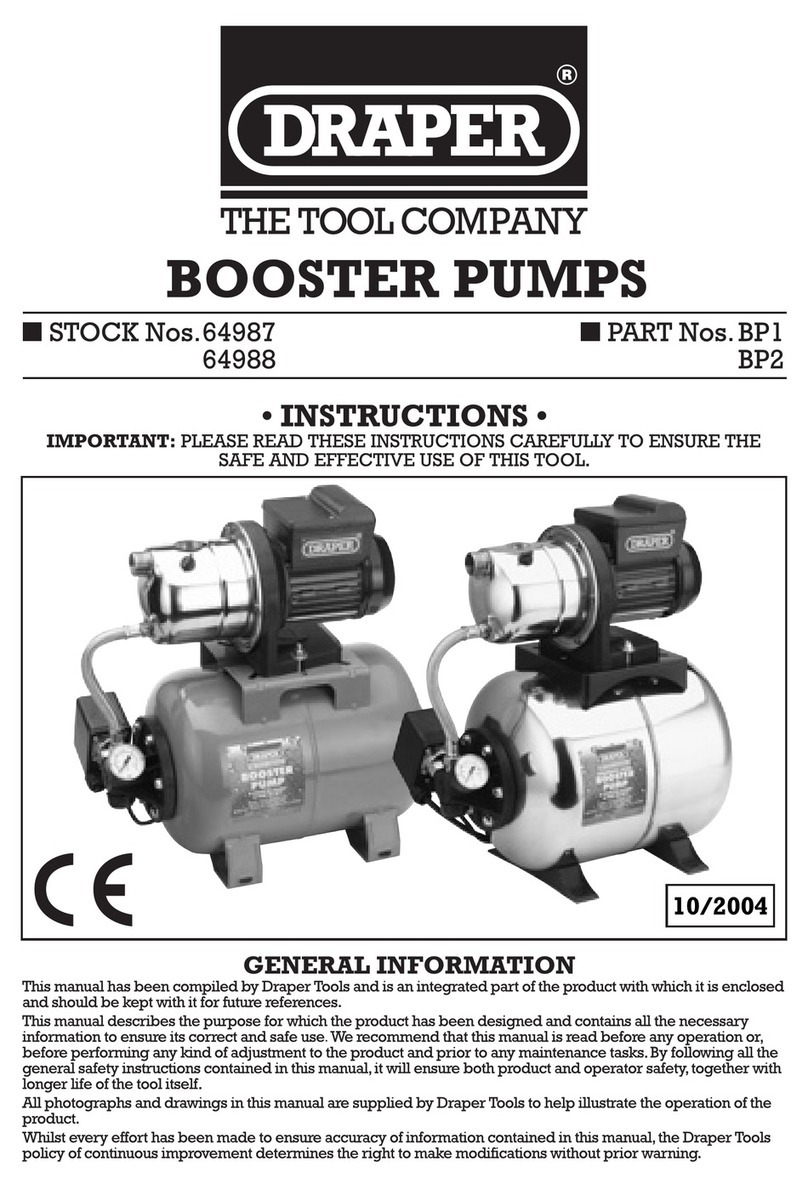

Single Shallow Well (Figure 1)

The single shallow well is typically a drilled well with

a 4" or 6" steel or plastic casing running vertically

into the ground. The surface of the water should not

exceed 25 feet in depth.

Connect the foot valve to the rst length of

suction pipe and lower into well. Add pipe sections

as needed, securing them using one of the sealing

methods previously mentioned. The foot valve should

be AT LEAST ve feet below the surface of the water

to allow for water draw down.

Seal the top of the 4" or 6" well casing with a well

seal to prevent debris from falling into the well.

1-1/2" MINIMUM

RIDGED PVC PIPE

1-1/2" MINIMUM

PVC ADAPTER

1-1/2" MINIMUM

FOOT VALVE

1-1/2" PVC

ELBOW

WELL

SEAL

Figure 3

Figure 1

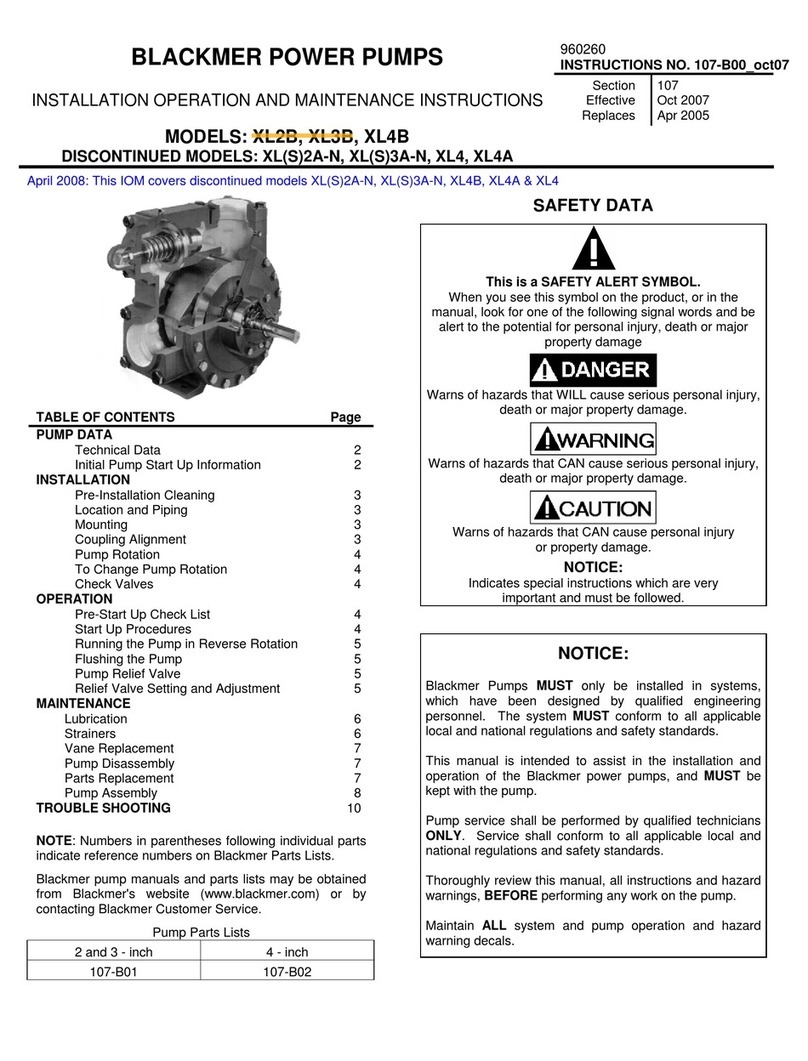

Multi-shallow Well Points (Figure 2)

The multi-point shallow well conguration consists of

two or more wells as a water supply. The wells should

be at least ve feet apart. The wells may be spaced

as a straight line (two or more wells), a triangle (three

wells), or a square (four wells).

Install a check valve or a ne screen well point

on each well to ensure the pump maintains prime.

The ow arrow on a check valve must point toward

the pump.