ATTENTION INSTALLER: PLEASE READ AND FOLLOW THESE INSTALLATION GUIDELINES.

FAILURE TO FOLLOW INSTALLATION GUIDELINES MAY VOID WARRANTY.

A drive is a sensitive piece of power electronics that, when installed properly, will provide you with years of trouble-free operation.

While our drives have many built-in protective features, if the installation or application is incorrect, failures due to improper

protection or installation will not be covered under warranty. To avoid this ugly situation we have developed the Drive Installation

ABC’s. Know these basic ABC’s with every drive you purchase. An incorrectly applied or installed inverter can result in system

malfunction or reduction in product life as well as component damage. You must read and understand the manual thoroughly

before proceeding.

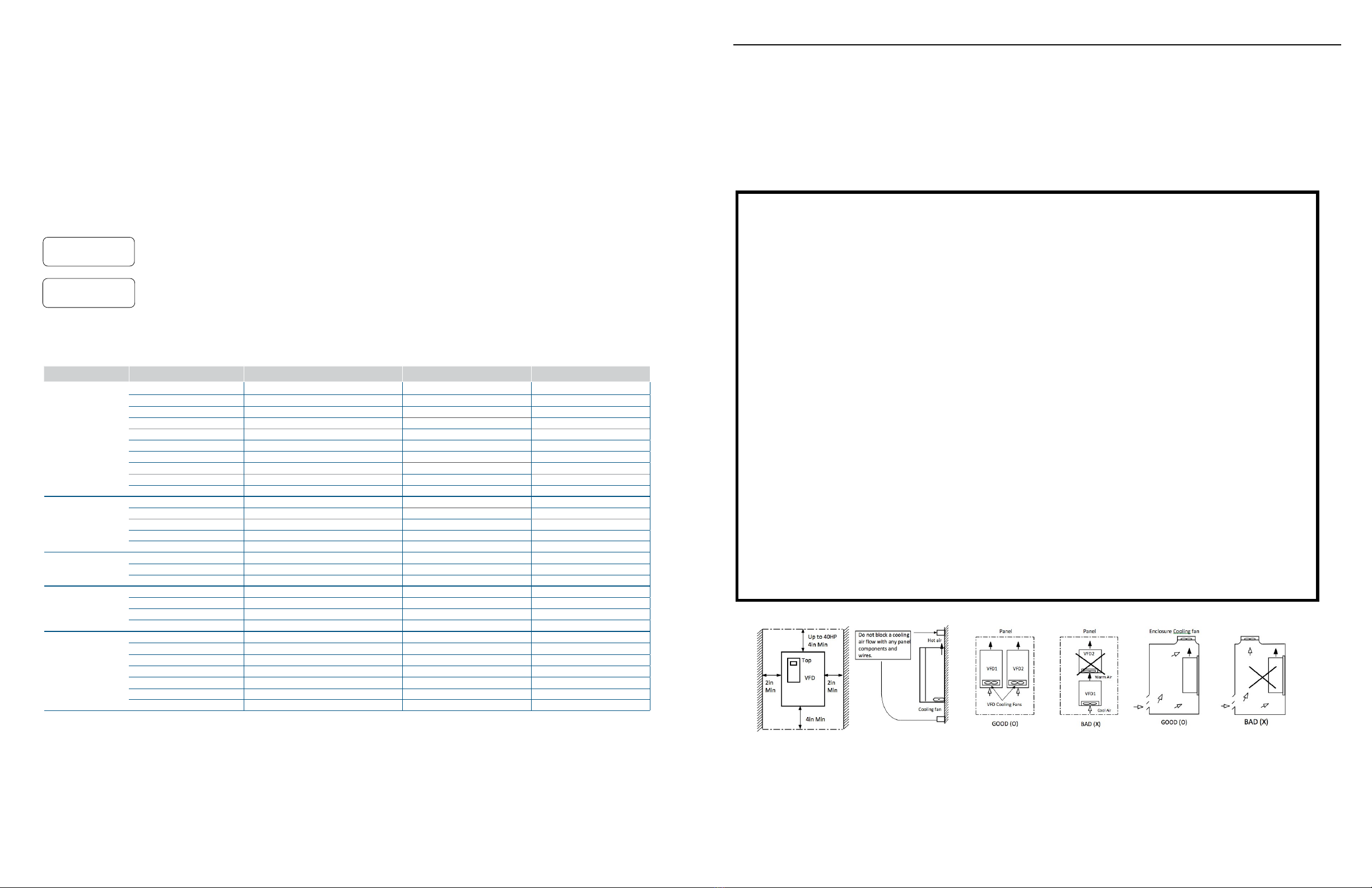

Installation Precautions

1) Handle the VFD with care to prevent damage to

the plastic components. Do not hold the VFD by

the front cover.

2) Do not mount the VFD in a location with vibration

(level higher than 5.9 m/sec2) such as installing the

VFD on a press or other moving equipment.

3) Install in a location where temperature is within the

permissible range.

4) The VFD can be hot during operation. Install it on

a non-combustible surface.

5) Mount the VFD on a flat, vertical, and level surface.

VFD orientation must be vertical (top up) for proper heat

dissipation. Also leave sufficient clearances around the

VFD. Increase minimum clearance by one inch for 50~75 HP

VFDs, by two inches for 100~150 HP VFDs, by three inches

for 200~300 HP VFDs, by four inches for 350~700 HP VFDs

to provide sufficient cooling airflow.

6) Do not mount the VFD in direct sunlight or near other

heat sources.

7) The VFD should be mounted in a Pollution Degree

2 environment. If the VFD is going to be installed

in an environment with a high probability of dust,

metallic particles, mists, corrosive gases, or other

contaminates, the VFD must be located inside the

appropriate electrical enclosure of the proper NEMA

or IP rating.

8) When two or more VFDs are installed or a ventilation

fan is mounted in the VFD panel, the VFD and

ventilation fan must be installed in proper positions

to keep the internal ambient temperature of the VFD

below the permissible value. If they are installed in

improper positions, the ambient temperature of the

VFD will rise.

9) Install the VFD using screws or bolts to ensure the

VFD is firmly fastened.

The ABC’s:

Form CVFDW1 - Ver. 2 Franklin Electric Warranty Registration Form for Variable Frequency Drives

Franklin Electric cannot provide technical support until the installer completes this form and files it with Franklin Technical Support. Only Franklin certified

personnel may use this form for Franklin (Titan) Variable Frequency Drives.

Date of start-up

VFD 1 VFD 2 VFD 3

Part #

Serial #

INSTALLATION INFORMATION

Motor Data

Insulation Class/Rated Voltage

Horsepower/Full Load Amperage HP/ FLA

Service Factor/RPM

Application

Torque constant variable constant variable constant variable

Input phase three-phase single-phase

Description

(i.e. pump jack, centrifuge, fan, blower, etc.)

Maximum & Minimum

Environmental Temperature °F

Distances in feet from VFD to motor

to service

transformer

Startup information

VFD Output Current Parameter

Reading @ Max Speed Amps

Speed control

Keypad 0-10V

Potentiometer 4-20mA

Communication Card

Enclosure NEMA rating 13R 12 4 or 4X 1 3R 12 4 or 4X 1 3R 12 4 or 4X

Check proper wiring & grounding

YES YES YES

VFD parameters set according

to quick start guide?

INSTALLER INFORMATION PURCHASER INFORMATION

Name

Phone

Company/Address

Installation date Install Location Purchase date PO #

Date of start-up Date of start-up

to motor

to service

transformer

to motor

to service

transformer

Input Voltage on VFD terminals

R, S, & T R-SS-TR-T R-S S-TR-T R-SS-T R-T

PID

Keypad 0-10V

Potentiometer 4-20mA

Communication Card PID

Keypad 0-10V

Potentiometer 4-20mA

Communication Card PID

VFD enclosed by?

Enclosure dimensions in inches

Cooling Fan/AC Unit Size

H W D H W D H W D

/ VIns.

Ins.

HP/ FLA HP/ FLA

SF/ RPM

SF/ RPM

SF/ RPM

Max: °F

Min: °F

Max: °F

Min: °F

Max: °F

Min:

(see manual

for parameter) Amps

(see manual

for parameter) Amps

(see manual

for parameter)

Environmental Conditions

(Please select all applicable conditions)

Indoor Dirt/Debris

Outdoor Moisture

Direct Sunlight Chemicals

YES NO YES NO YES NO

Please complete the fields below if the VFD is installed in an enclosed package that was not built by Franklin Electric.

Indoor Dirt/Debris

Outdoor Moisture

Direct Sunlight Chemicals

Indoor Dirt/Debris

Outdoor Moisture

Direct Sunlight Chemicals

Franklin Customer Not

Enclosed

Fan (In.) /AC(BTU) Fan (In.)/AC (BTU)Fan (In.)/AC (BTU)

xaFliamE

Name

Phone

Company/Address

xaFliamE

PURCHASER INFORMATION

Installed Devices

(Indicate the letters of installed devices

shown in diagram above. i.e., A, B, D, F)

Input Contactor

Lightning

Arrestor

Short Circuit Protection

and Disconnect Input Line Reactor

Variable Frequency Drive

Output Reactor

Motor Disconnect /

Contactor Aux. Motor

Harmonic Filter

Motor Guard Filter

I

Motor

Disconnect /

Contactor

AB

C D

E

G H

J

Power

Source EMI/RFI Filter

F

three-phase single-phase three-phase single-phase

Model Number of Dynamic

Brake Unit / Resistor

(if applicable) DB Unit /Resistor DB Unit /Resistor DB Unit /Resistor

Please fax this form to (503) 643-4925 or mail to 22995 NW Evergreen Parkway, Suite 100, Hillsboro, Oregon 97124.

This form is also available to download (www.cerusind.com/library) and filed electronically by email to techsupport@cerusindustrial.com

NOTE: Failure to complete this form may delay warranty processing.

Franklin Customer Not

EnclosedFranklin Customer Not

Enclosed

• Ambient Temperature - of the installation

• Bonding - make sure your grounding is correct

• Clean Power and Air flow - for proper cooling

• Correct Sizing - for the application

Factory Programmed Parameters

Function Parameter Description Submersible Circulating

Setup

SET-04 Motor RPM 3600 rpm 1800 rpm

SET-11 VFD acceleration time 2 sec 20 sec

SET-12 VFD deceleration time 2 sec 30 sec

SET-16 Stop mode Coast Decel

SET-20 PID Operation YES YES

SET-21 PID Feedback Signal I (4-20mA) I (4-20mA)

SET-22 Feedback unit PSI PSI

SET-25 Transducer Range 100 PSI 100 PSI

SET-26 & DRV-00 Pressure Set-Point 50 PSI 50 PSI

SET-27 PID low limit frequency 30hz 30hz

Sleep Mode

SET-32 Sleep Frequency 35hz 35hz

SET-33 Sleep mode delay time 10 sec 20 sec

SET-34 Sleep mode boost value 3 PSI 2 PSI

SET-35 Sleep mode wake-up level 8% 2%

SET-47 Sleep Boost Timer 10 sec 10 sec

Pipe Fill

SET-36 Pre-PID frequency 0.0 Hz (disabled) 0.0 Hz (disabled)

SET-37 Pre-PID delay time 180 sec 60 sec

SET-38 PrePID exit level 25 PSI 25 PSI

Broken Pipe

SET-40 Broken pipe enable NO NO

SET-41 Broken pipe frequency 59Hz 59Hz

SET-42 Broken pipe delay time 30 sec 30 sec

SET-43 Broken pipe feedback level 35PSI 25 PSI

Underload

SET-74 Level detection enable Under Level NO

SET-75 Level detection source Current (underload) Current (underload)

SET-76 Level detection frequency 59.0 Hz 59.0 Hz

SET-77 Level detection delay time 1 sec 1 sec

SET-78 LDT Level 0.0A 0.0A

SET-80 Level detection trip enable YES YES

SET-81 Well ll time 60min 0 min

Saving parameters to the keypad is recommended after the start-up is performed and you are satised with pump system operation. If the

programming is changed later and your VFD is no longer operating the way you intended it to, you can always load your previously saved

parameters from the keypad. Additionally, the programmed keypad can be used to copy same parameter settings to another VFD.

SAVE PARAMETERS TO KEYPAD: Change FG2-91 to YES to save parameters to the keypad. After pressing

ENTER key, this parameter will go back to NO after saving is done (approximately one minute).

LOAD PARAMETERS FROM KEYPAD: Change FG2-92 to YES to load parameters from the keypad. After

pressing ENTER key, this parameter will go back to NO after loading is done (approximately one minute).

FG2Para.Read

91 Yes

FG2Para.Write

92 Yes

- Saving Parameters

System Validation

1. Switch HOA in the AUTO position with low demand and run VFD for one minute after the system is at pressure set-point. The VFD

should maintain a set-point and not go into sleep mode.

2. Close demand completely and VFD should drop frequency to minimum and after delay time it should boost system pressure (if boost

is enabled) and go to sleep mode.

3. Open low demand and VFD should wake up after pressure drops below the wake-up pressure.

4. Run VFD with different demand levels to check if control is stable.

franklin-controls.com | 800.962.3787