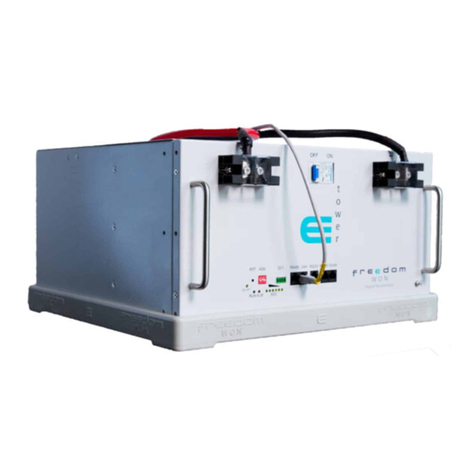

Freedom Lite Installation Manual Revision 10

6. CAN Bus Sockets x 2 (RJ45) (one socket must contain a termination resistor if end of

line)

7. DB9 Programming Port (not visible in photo)

8. Reset Button

9. State of Charge Display

10. Error Lite

11. On Button

12. Off Button

13. Safety Retaining Tabs

14. Lifting Eye Bolts

15. Feet

16. Power Level Designator (absent for standard model) – note, the HP models have

become the new standard models as of 1 April 2019 and the HP upgrade is no longer

available

17. WiFi Connect Data Logging and Reporting

18. Override Button

For the 52V models the absolute maximum allowable voltage when fully charged is 56V,

however a more typical inverter setting range is 55.5V to 55.8V, depending on the inverter

voltage tracking accuracy in preventing a voltage overshoot above 56V. The voltage

normally used as the minimum cut off is 48V, however this will not typically be reached if

operating down to 90% Depth of Discharge (DoD). The BMS will command the connected

inverter with CAN Bus interface to stop discharging the battery at 10% SoC (90% DoD),

which roughly equates to 49,0V). Under high load the voltage may drop to 48V whilst still

above 10% SoC. A voltage of 48V or even lower can be observed where the standby current

draw on the inverter has caused the battery to be discharged below 10% SoC or below the

48V minimum cut off voltage. The battery breaker will eventually trip the battery at around

47V to protect the cells from undervoltage.

The Commercial HV models operate at 512V for most models as this is the ideal operating

voltage for the ATESS battery inverters (a common pairing). There are three models with

different voltages because of the differing cell architecture required to build these models –

refer to specification sheet for more details.

The weight of each model is given in the tables 2.1 and 2.2. The Freedom Lite Commercial

100/70, 120/84 and 140/98 are assembled complete in the Freedom Won factory as

standard. The 160/112 up to the largest 700/490 are either assembled on site by a Freedom

Won site team or, if preferred by the client, can be built into a container at Freedom Won

by the Freedom Won factory team.

The 100/70, 120/84 and 140/98 models require specific lifting equipment to place them into

position. Should a specific site present logistical constraints in relation to placing these

models into position, it is possible to request that Freedom Won assemble the batteries on

site at an additional cost.

Page 4 | 28