Freedom LiTE Installation Manual Revision 14

P a g e 2 | 30

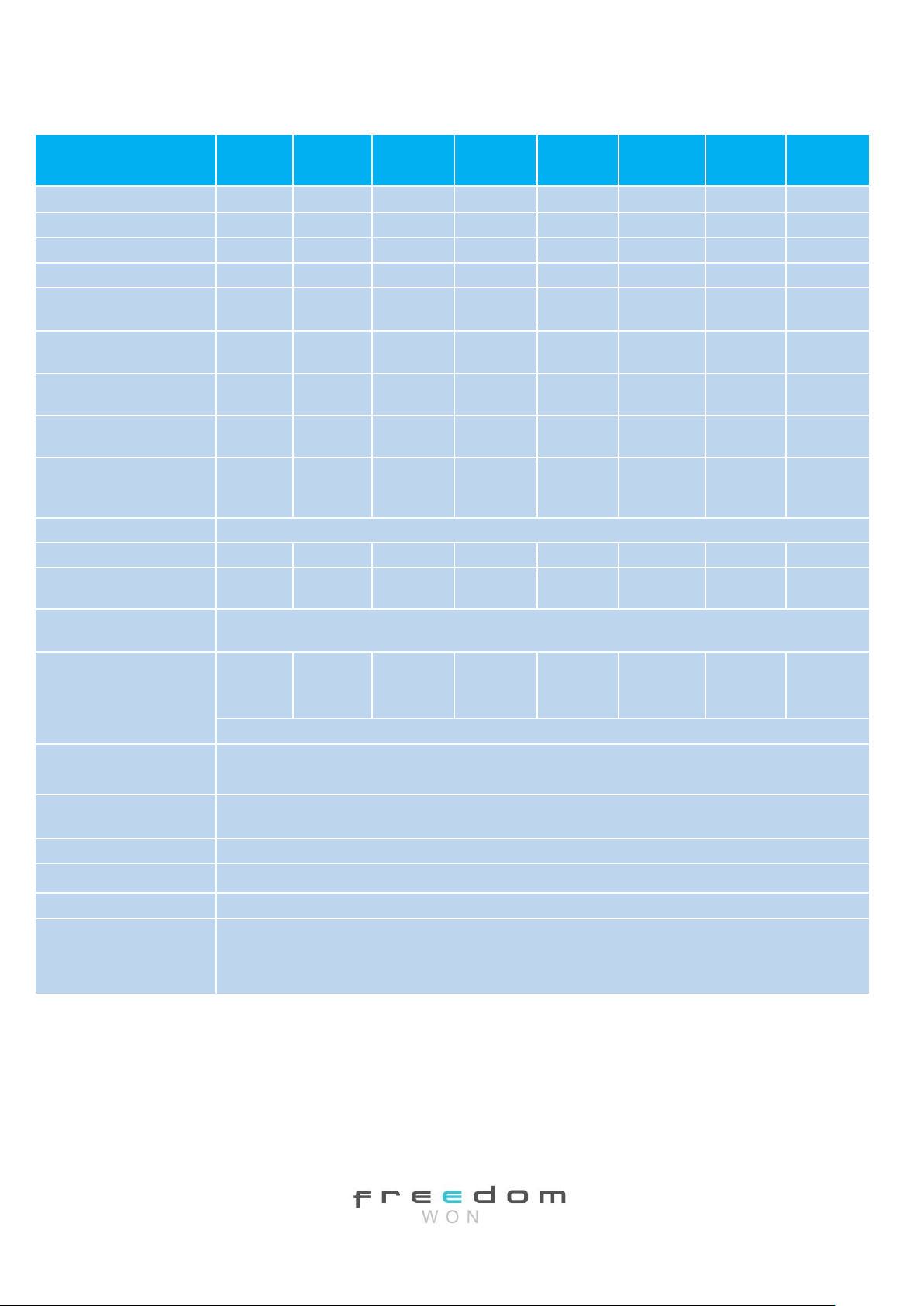

Table 2.1 provides an overview of the 52V Freedom LiTE Home and Business range. There

are eight Freedom LiTE models in the Home and Business range, as included in the table,

classified in terms of energy capacity.

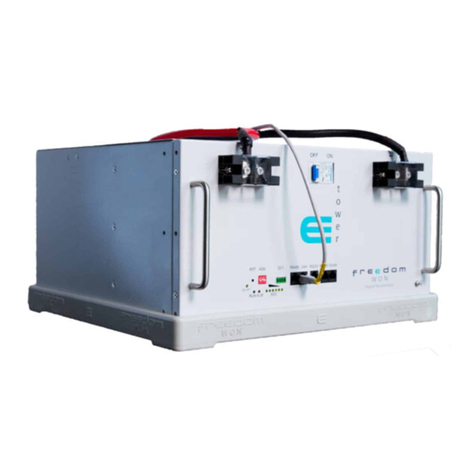

An image with numbered labels pertaining to the following paragraphs is provided in Figure

2.1. The model number denotes with the first number [1] the total energy storage capacity

in kWh of each model. The second number [2] denotes the maximum amount of energy in

kWh that should be withdrawn per daily cycle (on average) in order to optimise the life of

the lithium cells. This equates to 80% of the total for each model i.e. 80% depth of discharge

(DoD). Note that all Freedom LiTE batteries offer a maximum of 90% DoD as standard.

The range is very compact with the “Home” models up to the LiTE Home 20/16 intended to

be wall or floor mounted –all models are supplied standard with “keyholes” on the back for

wall mounting or plastic feet for floor mounting. The larger “Business” range is designed for

floor standing only, with either plastic feet or aluminium feet with plastic pads on the

underside.

The Ah capacity is also provided in the tables for each model for easy reference.

The maximum current for each model is governed by the rating of the built-in circuit breaker

[3], which has been sized below the maximum current capability of the lithium cells. There is

no significant cell temperature rise during operation and no active cooling of the cells is

required for this range of models. The time limit for operation at the maximum current is 30

seconds in a 60 second cycle. To ensure that the circuit breaker does not trip in normal

operation it is advised that the design of the system aims to remain at or below the

continuous current value.

For the 52V models the absolute maximum allowable voltage when fully charged is 56V,

however a more typical inverter charge setting is 55.8V. The voltage normally used as the

minimum cut off is 48V, however this will not typically be reached when operating down to

90% Depth of Discharge (DoD). The BMS will command the connected inverter with CAN Bus

interface to stop discharging the battery at 10% SoC (90% DoD), which roughly equates to

49,0V). Under high load the voltage may drop to 48V whilst still above 10% SoC. A voltage of

48V or even lower can be observed in systems without a CAN Bus interface or where the

standby current draw on the inverter has caused the battery to be discharged below 10%

SoC. The battery breaker will eventually trip the battery at around 47V to protect the cells

from undervoltage.