10 7

MAINTENANCE AND TROUBLESHOOTING

For optimal performance of the strength equipment and to reduce the chances of injury to users, you must per-

form preventive maintenance on a regular basis. Instruct all personnel to perform the procedures described in

this section. Personnel must also record and report any accident. To maintain the strength equipment’s warran-

ty, use only FREEMOTION EPIC parts for repair or replacement. If there are any questions or concerns, see

HOW TO CONTACT CUSTOMER CARE on the back cover of this manual.

DAILY MAINTENANCE

Upholstery and Frame—General Cleaning

1. Clean the strength equipment using a soft cloth

dampened with a light solution of mild soap and

warm water. If necessary, use a soft bristle brush

with the cleaning solution.

2. Rinse the area thoroughly using a soft cloth damp-

ened with clean water and dry thoroughly.

Upholstery—Difficult Stains

1. Spray the stain with a non-abrasive household

cleaner such as FORMULA 409®cleaner, SIMPLE

GREEN®,or a similar product. Rub the stained

area gently and let the cleaning solution sit for a

few minutes.

2. Rinse the area thoroughly using a soft cloth damp-

ened with clean water and dry thoroughly.

3. Repeat these steps if necessary using a soft bristle

brush.

Optional Method for Difficult Stains

1. Rub the stained area gently using a soft cloth

dampened with rubbing alcohol.

2. Rinse the area thoroughly using a soft cloth damp-

ened with clean water and dry thoroughly.

CAUTION: When using any cleaning product, try it

first in an unnoticeable place to ensure that there is no

damage to the material. Follow the directions and the

safety precautions of the manufacturer of each clean-

ing product used. FreeMotion Fitness and its vendors

cannot be held liable for damage or injuries resulting

from the use or misuse of cleaning products.

Important: Do not use abrasive cleaners, which may

scratch the strength equipment. Strong cleaners and

abrasives will damage decals; use caution around

decals. Do not use solvents such as lacquer thinner,

kerosene, gasoline, or similar liquids.

WEEKLY MAINTENANCE

Hardware

Check all nuts and bolts and tighten them as required.

Important: All FREEMOTION EPIC cushions have

dense plywood supports with tee-nuts that are used to

bolt the cushions to the strength equipment. Because

the tee-nuts are held by the plywood, they will not

withstand the torque that standard nuts and bolts will.

When tightening the bolts securing a cushion, turn

them only until they are snug and the cushion does

not move or feel loose. Overtightening may strip the

tee-nuts from the plywood and make it impossible to

remove the cushion in the future.

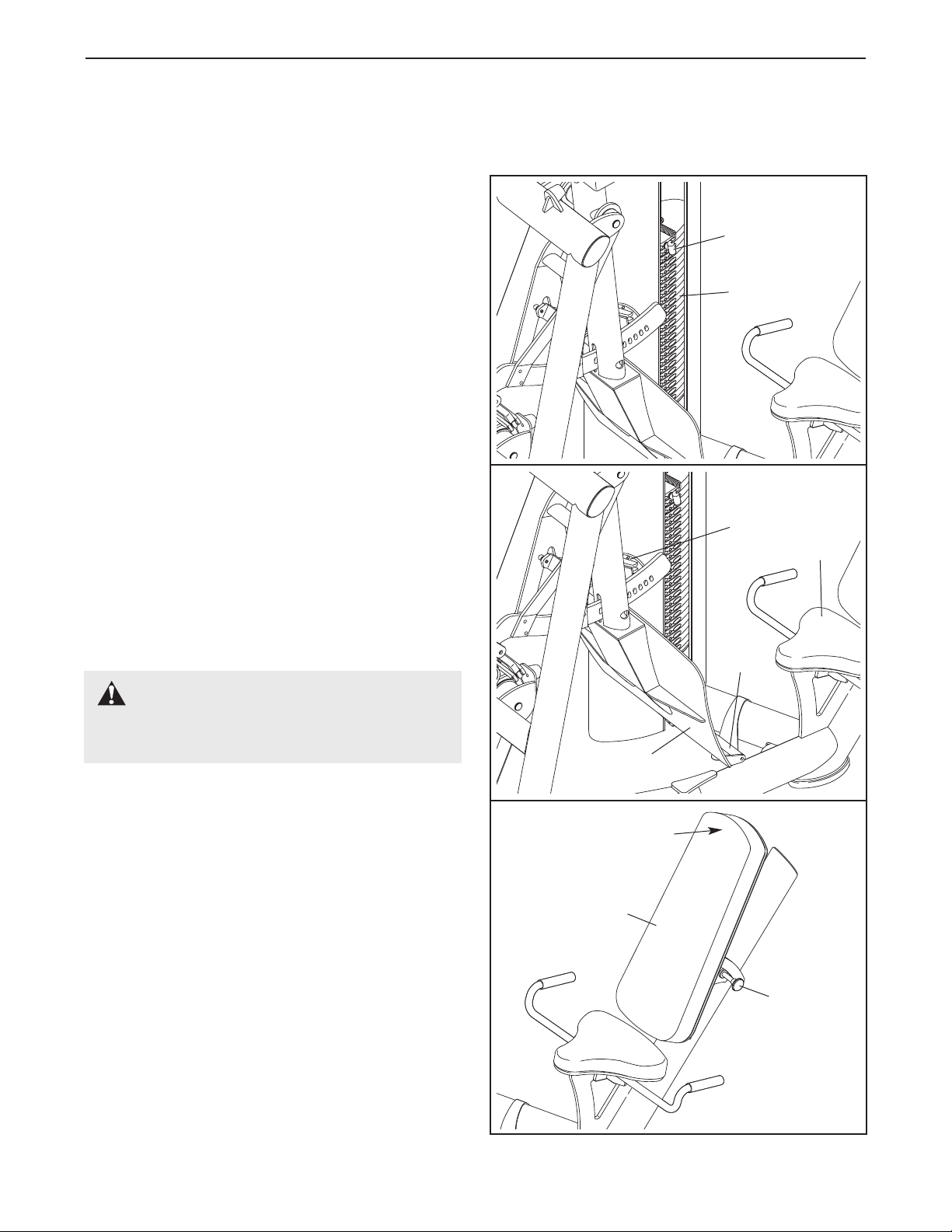

Cables

1. Check each cable for proper tension (see CABLE

ADJUSTMENT on page 8).

2. Check the entire length of each cable by slowly

performing one repetition on the strength equip-

ment; inspect the cable that is exposed on the

exterior of the strength equipment and the cable

inside the tower. Run your fingers along the cable,

paying close attention at the bends and attachment

points. Watch for the following conditions, which

may indicate a worn cable in need of replacement:

A. atorn or split cable sheath that exposes the

cable

B. a kinked or severely bent cable

C. a curled or twisted sheath

D. a stretched cable sheath, showing a thinning

cross-section

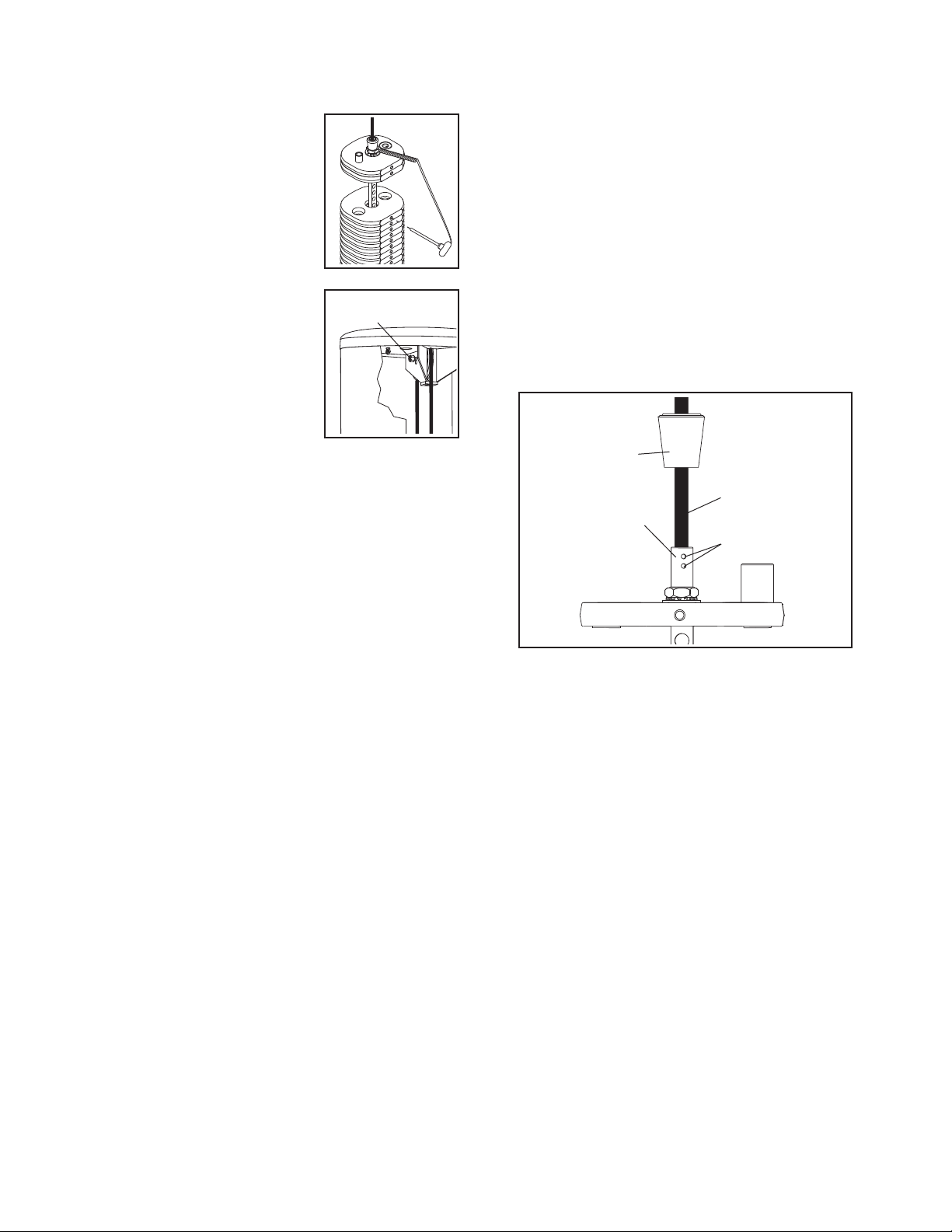

WEIGHT STACK SERVICING

Servicing the weight stack involves replacing the two

guide bushings and weight insert in the top weight. To

order these parts, see HOW TO CONTACT CUS-

TOMER CARE on the back cover of this manual.

1. Remove the wingnuts under the tower cap and

remove the tower cap from the tower.

2. Remove the guide rod nuts and washers from the

top of each guide rod.

3. Lift the coupler cover and loosen the four set

screws—this will release the cable.

4. Lift the guide rods out of the top of the tower.

5. Remove the rod nut, rod star washer, and rod

washer from the top of the weight rod. Lift and

rotate the top weight, and remove it through the

front opening of the tower.

6. Use a punch to drive the two existing guide bush-

ings and the weight insert out of the top weight.

7. Hold one of the new guide bushings square to the

face of one of the holes in the top weight, place a

protective piece of wood on top of the guide bush-

ing, and lightly tap the guide bushing until it is flush

with the surface. Insert the other guide bushing

and the weight insert in the same way.

8. Replace the top weight. Next, tighten the rod nut,

rod star washer, and rod washer onto the weight

rod.

9. Reattach the cable to the top weight coupler.

Retighten the four set screws into the threaded

holes. Tighten the set screws equally until they

contact the cable. Then, tighten each screw alter-

nately 1/4 turn, until all are set to 150 inch/pounds

(17 Newton-meters).

10. Clean and lubricate the guide rods by wiping them

with a soft cloth containing a lightweight motor oil,

10W-40 or 10W-30 weight. Apply only a light coating

over the entire length. Do not use TEFLON®or sili-

cone-based lubricants.

11. Reinsert the guide rods through the top of the tower

and into the weight stack. Note: If the weight stack

has shifted, use a short bar to realign the holes in

the weight plates. Hold the weight plates while

inserting the guide rods.

12. Reattach the guide rods to the top of the frame with

the two guide rod nuts and washers.

13. Insert the weight pin into the top weight. Slowly per-

form a repetition, lifting the top weight as far as

possible. Then, slowly lower the top weight. If the

top weight sticks, loosen one of the guide rod nuts.

Slowly perform another repetition. Retighten the

guide rod nut. Check the full travel again and read-

just the guide rod nuts as necessary.

14. Slowly perform a repetition using a light load and

have someone make sure that the cable is not

derailed from a pulley or rubbing on a cable

guard.

15. Replace the tower cap and retighten the wingnuts

onto the bolts.

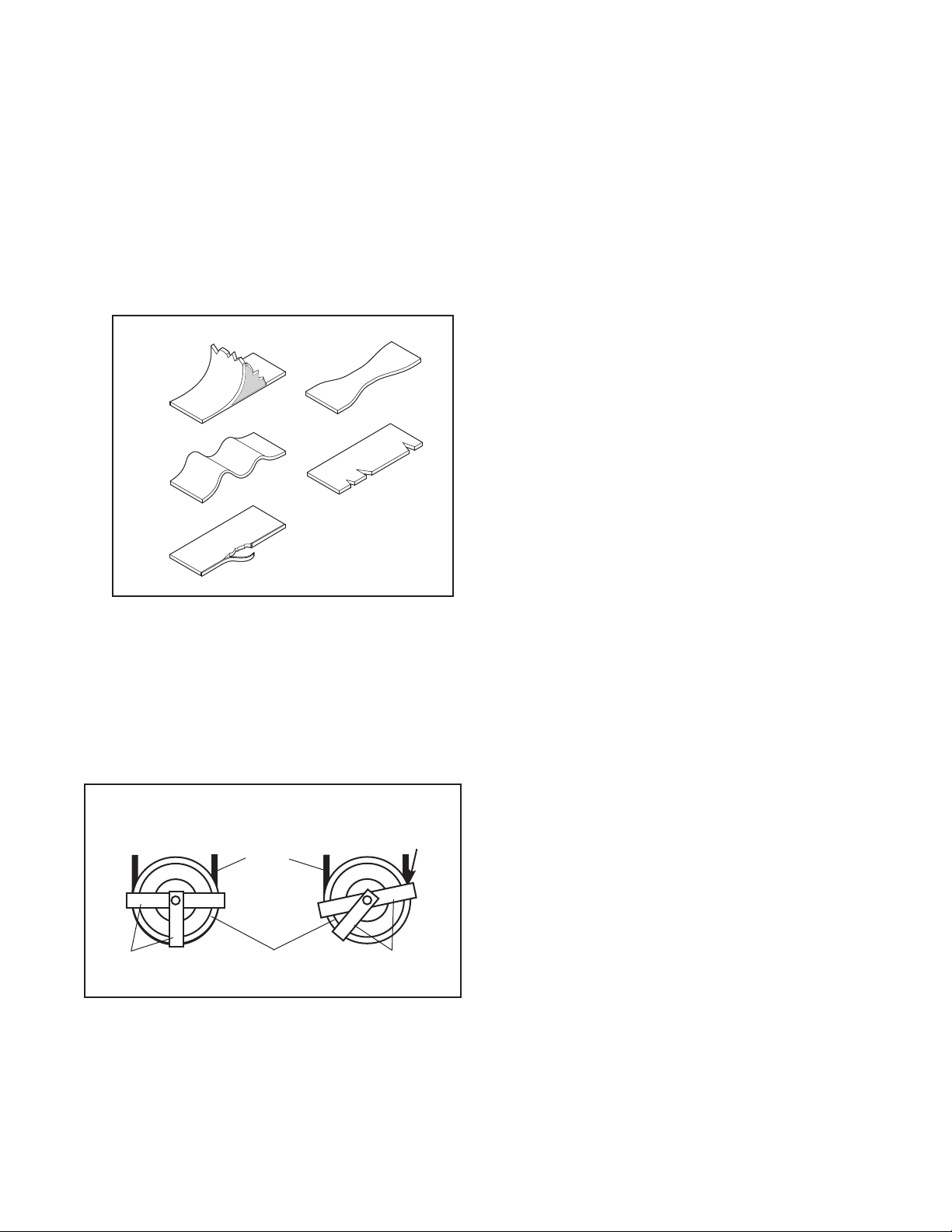

Weight

Insert

Guide

Bushing

Guide

Bushing

Top Weight

Top Weight

Coupler

WARNING: Do not force the

guide rods into the weights; doing so will

damage the bushings and weight inserts.

A

B

D

C