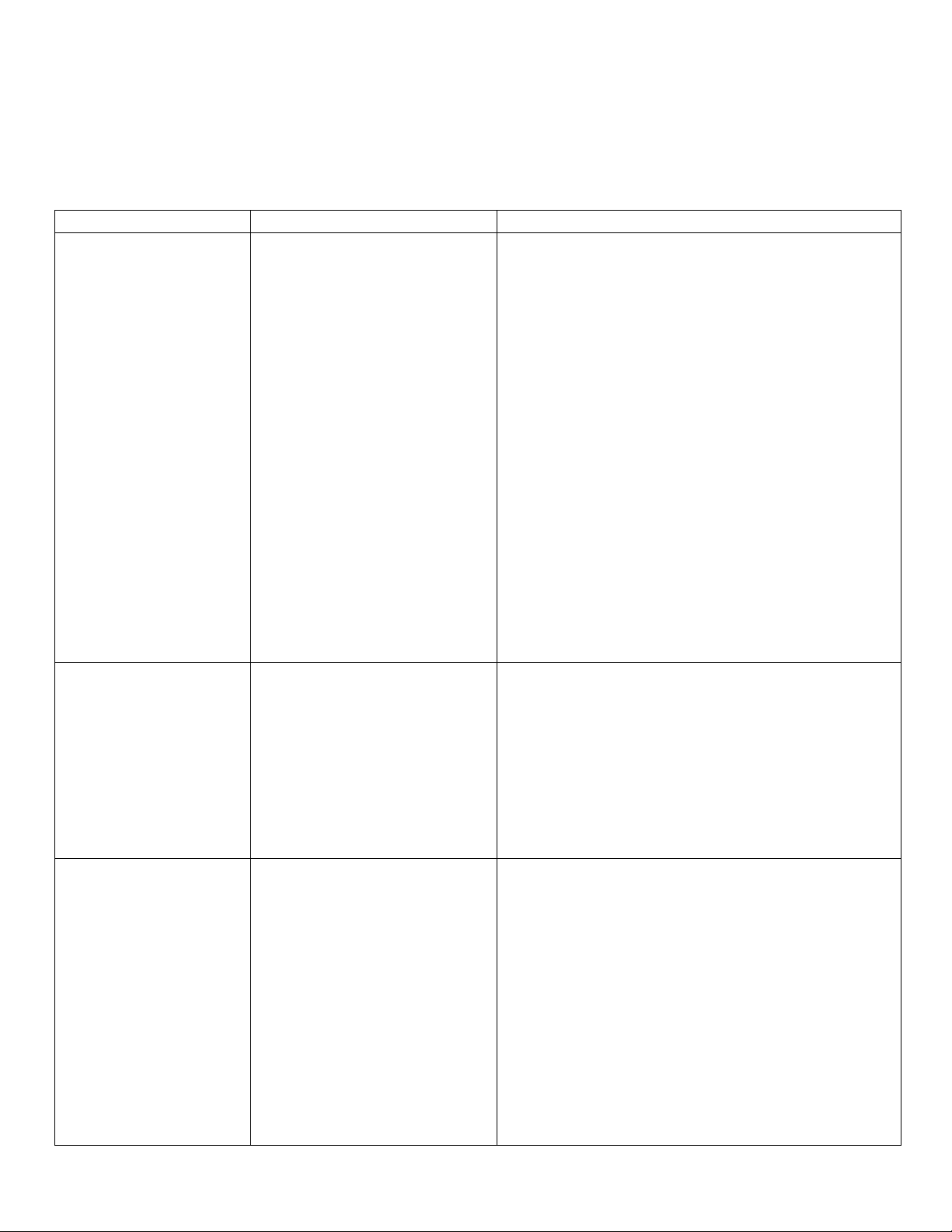

Park Smart System Diagnostic Table

TRUCK MUST BE IN PARKED MODE TO

PERFORM DIAGNOSTIC TESTS!

CORRECTIVEACTION / SEE APPENDIX

Unit Runs - But Does Not

Blow Cold Air

1. Airflow blockage.

2. Compressor Fuse or Relay.

3. Compressor controller

connections.

4. Compressor controller board.

5. High pressure switch

6. Evaporator Sensor/Freeze

switch defective

7. Compressor thermal switch

8. Defective compressor

9. Blend door position.

10. Evaporator blower

11. Loss of charge (refrigerant

system not serviceable).

1. Clear any blockage from recirculation grill or louvers. Also

check condenser inlet and outlet for restriction (under

truck).

2. Check F1 fuse and PARKED MODE LS3 relay. See

appendix F and D

3. Confirm all wire harness plugs are connected.

4. Check Control PCB Assembly. See appendix I

5. Check pressure switch. See appendix E

6. Check freeze switch. See appendix G

7. Check thermal switch. See appendix H

8. Check power to compressor. See appendix I

9. Check blend door operation. See appendix M

10. Check Evaporator blower. See appendix K

11. If all tests check OK a loss of charge may have occurred.

1. Poor electrical connection.

2. Condenser fan inoperative.

3. Air flow blockage causing high

pressure or freeze condition.

1.

Check all electrical connections.

2.Check condenser fan. See appendix J

3.Check for restricted airflow under truck at condenser inlet

and outlet and at louvers and recirculation grill. Check

pressure switch and/or freeze switch. See appendix E and G

Unit Blows Cold Air, But

Low Airflow

1. Check all duct work

connections.

2. Air flow restricted

3. Evaporator Blower motor

inoperative.

1. Make sure all ducts are connected, sealed and secure.

2. Check for airflow at louvers and recirculation grill.

3. Check evaporator blower motor. See appendix K

Unit Runs Correctly, But

Less Than Expected Run

Time

1. Ground terminal(s).

2. AUX batteries weak or not

charged correctly.

3. Separator not functioning

correctly.

4. Trucks main batteries poor

condition

5. High amperage draw

6. Defective Outside air

temperature sensor.

1. Inspect and tighten ALL connections.

2. Check AUX batteries for condition and state of charge.

See appendix A

3. Check separator connections and operation. See

appendix B

4. Check Main truck batteries for condition and state of

charge. See appendix A

5. Use DC ammeter to check amps when running.

Excessive amperage could signal compressor or internal

component issue. Amperage ranges 40A to 75A

depending on conditions

6. Energy management will stop and amp usage will

increase.

7. See appendix O.

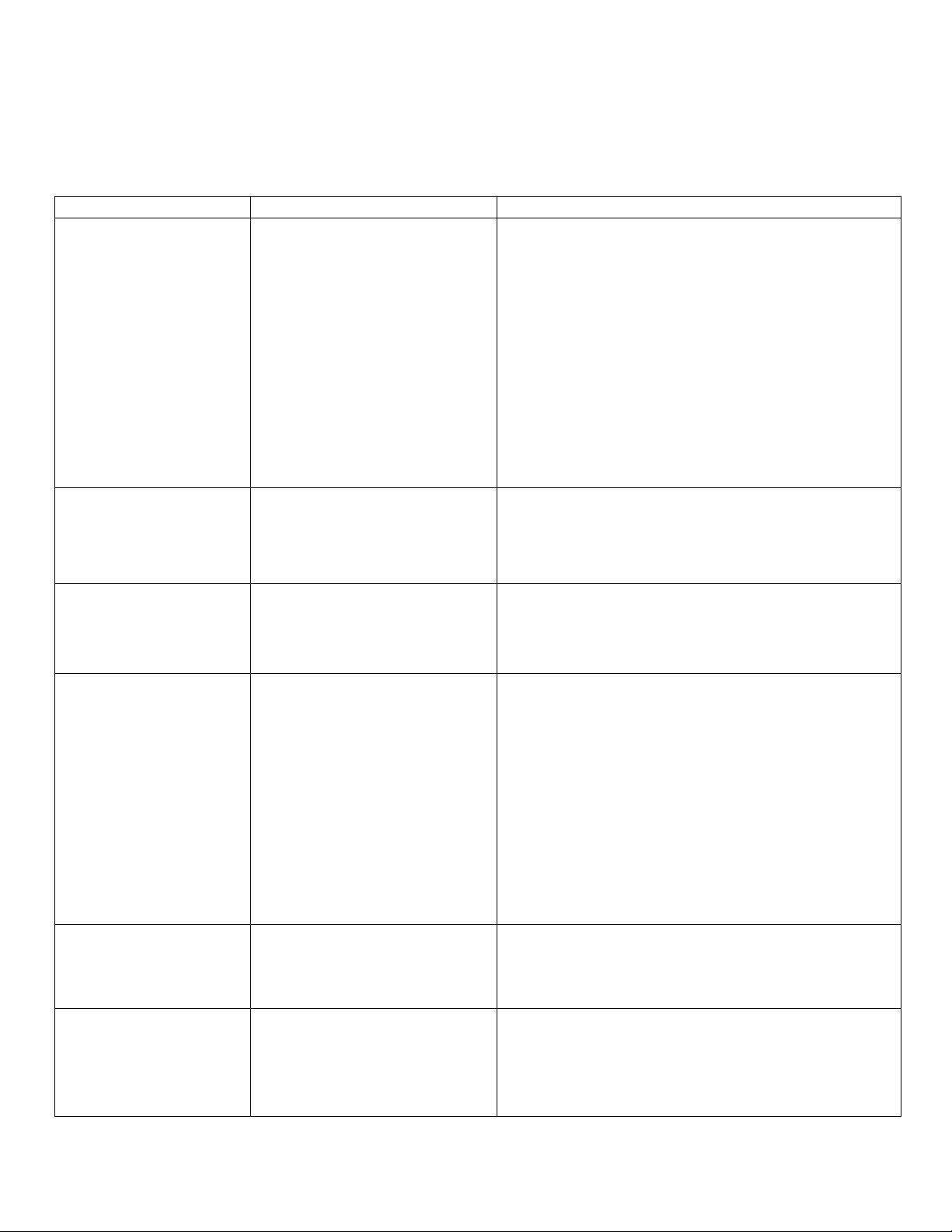

Unit is Noisy or Vibrates

1. Evaporator Blower motor.

2. Condenser fan motor.

3. Compressor mounting.

1. Check evaporator blower. See appendix K

2. Check condenser fan. See appendix J

3. Check rubber compressor mounts. See appendix L

Unit runs but does not blow

hot air

1. Heater power and ground

2. Heater fuse

3. Wiring harness

4. Heater enable signal

1. Check for power at the heater pins 1 & 2

2. Check heater fuse F3. See page 5.

3. Check wiring harness connectors and physical condition

4. Check for heater enable 12V at heater pin 7 from control

PCB assy, pin C15

NOTE: Heater diagnostics can be performed using Espar’s EDITH diagnostics lap top based program. You must have the ISO

cable adapter for the ParkSmart Hydronic heater. It is proprietary to Freightliner and other cable adapters will not interchange!