2. OPERATING DIRECTIONS

2.1 Purpose of use

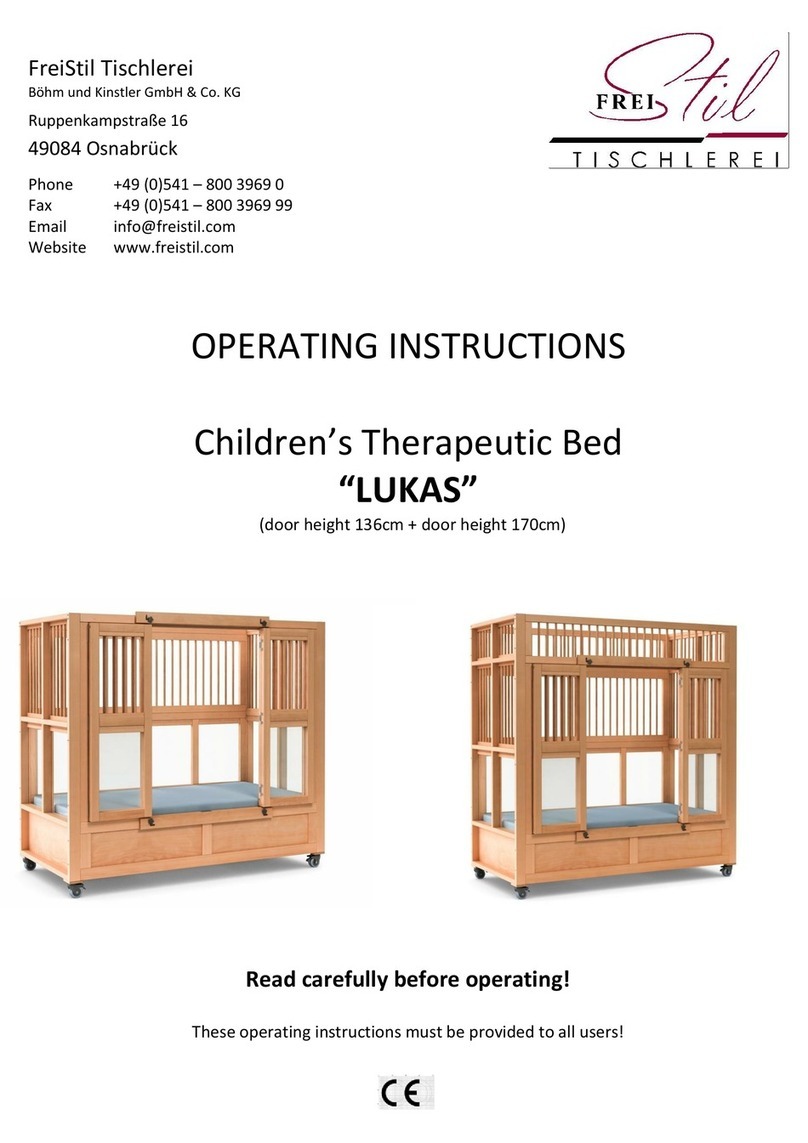

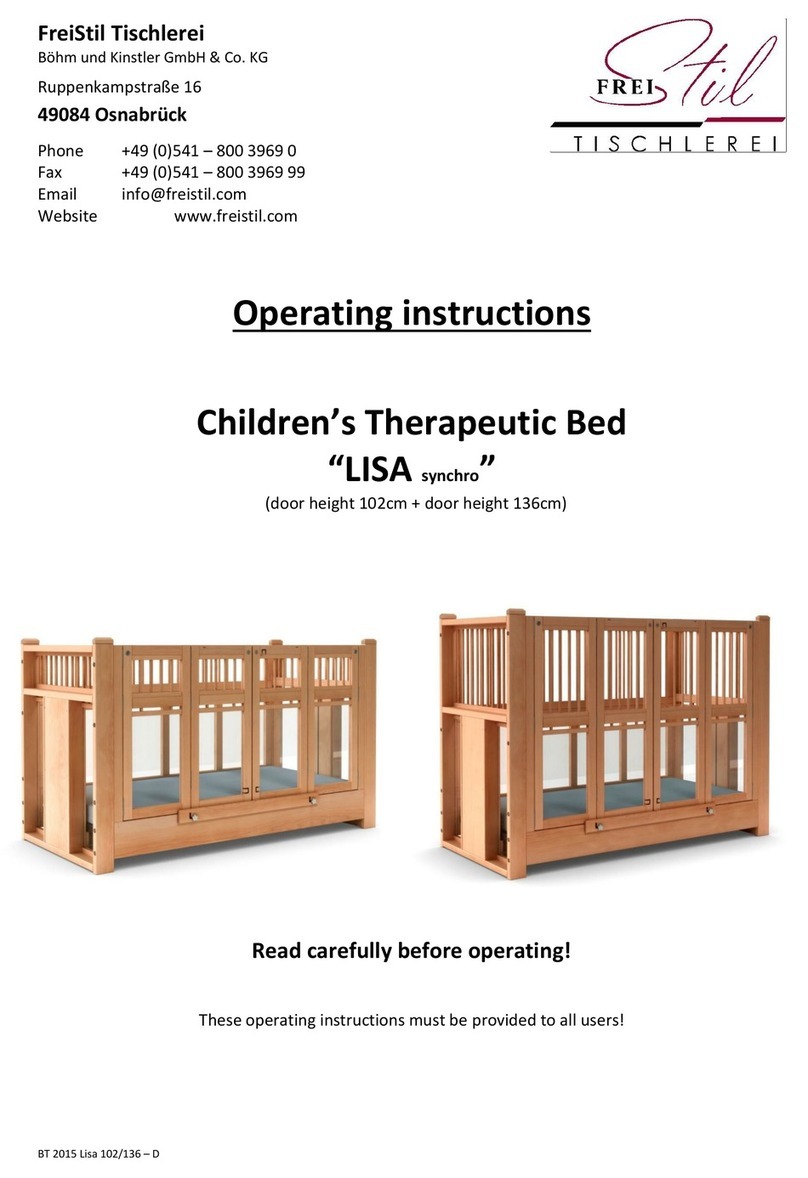

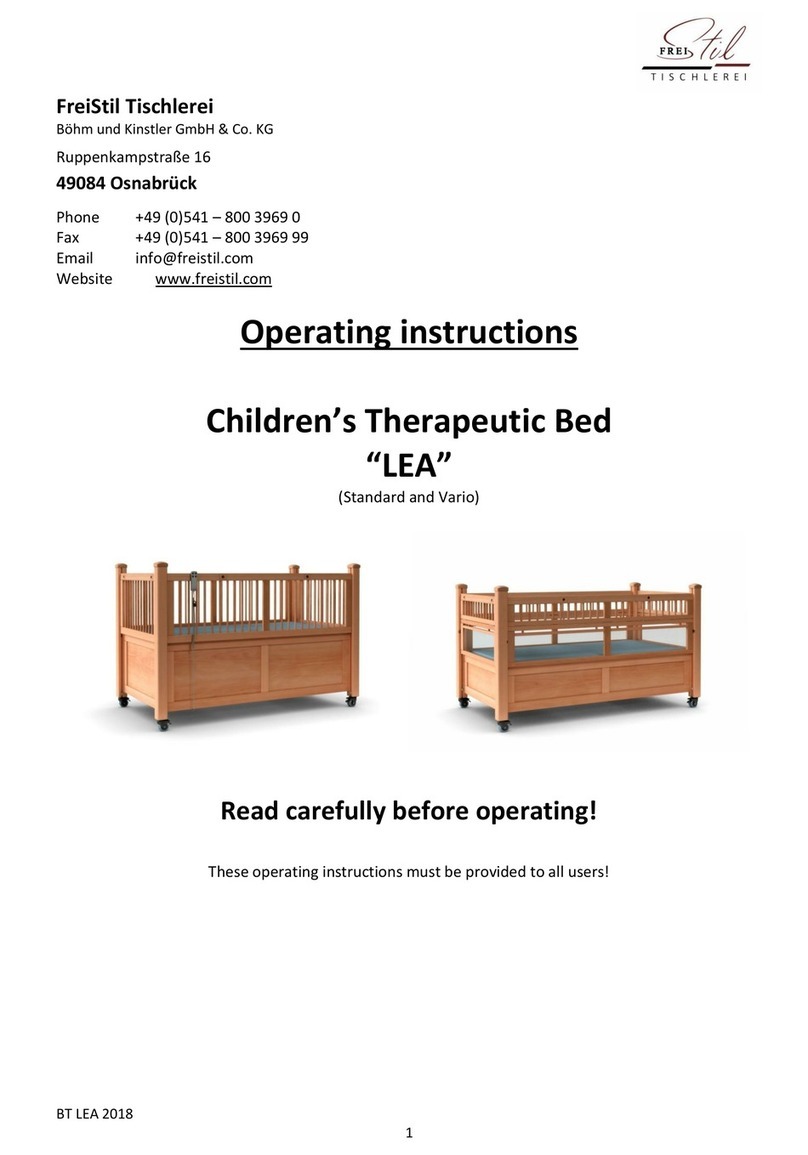

The children’s therapeutic bed „LEA” is designed for private use at home as well as for domestic

care. It’s medical objective is to provide the alleviation, treatment and surveillance of illness and

injuries by the various resting positions for the child. The multifunctional options increase the benefit.

For safety reasons the bed is not for use for medical treatments using electricity, since this model is

not conceived as a hospital bed. It is licensed for one (1) person only and the maximum patient

weight (see specification label) must not be exceeded. The bed is for indoor use only and has to be

protected from high humidity. All technical functions can be controlled by a lockable IPX4-manual

control unit with magnetic key.

All components of the bed are only permitted for use according to its intended purpose.

Overload may cause damage and is not permitted.

2.2 Important notes for operational safety

I. Set-up and initial operation have to be carried out by authorized distributors. A functional test

has to be carried out prior to handing the bed over to the customer. Attention has to be paid

to: the smooth running of all functions, the installation of power supply according to the

regulations, the firm installation of the lifting unit within the bed frame as well as the fitting of

the bed base to the lifting unit. This also applies to further operation of the children’s

therapeutic bed.

Improper installation of mains connection may cause serious damage (electric shock)

to people.

II. The maximum weight of the patient must not exceed 100 kg. People of any age with limited

perceptive faculty may operate the system under supervision only.

III. The lowest position of the bed base is the safest position and should be used in any case,

unless therapy + nursing require a different position.

After treatment always return the lifting unit to its lowest position.

IV. While moving the lifting unit make sure that no parts of the body

get in or under the moving elements. DANGER OF BEEING

CRUSHED!

V. The therapeutic bed for children „LEA” is designed for dry rooms

and must be used and stored in such rooms only.

The system may only be operated by state-of-the-art 230 Volt plugs. Cables + plugs have to

be dry. Make sure that cables are not crushed or do not rub against anything. Pay attention to

the proper laying and fixing of all cables at the positions advised.

VI. To avoid overload and defects of the electric engine the power-on time must not exceed a

maximum time of 2 minutes.

The electric adjustment for the head-end or the head- and foot-end must only be used

for lifting/ lowering the upper body or legs of the patient (patient must be in proper

position!). Overload causes damage and is not permitted!!!

Overloading the mechanical components causes damage and therefore is not permitted

(see Operational Manual TOP 2.3 + 2.4 as well as specification label).

VII. Liability for any kind of damages and injuries is explicitly excluded in case of misuse, improper

use, wrong operation or inexpert installation/repair. Furthermore all kinds of guarantees are

also excluded in such a case.

OM Lea – 06