9

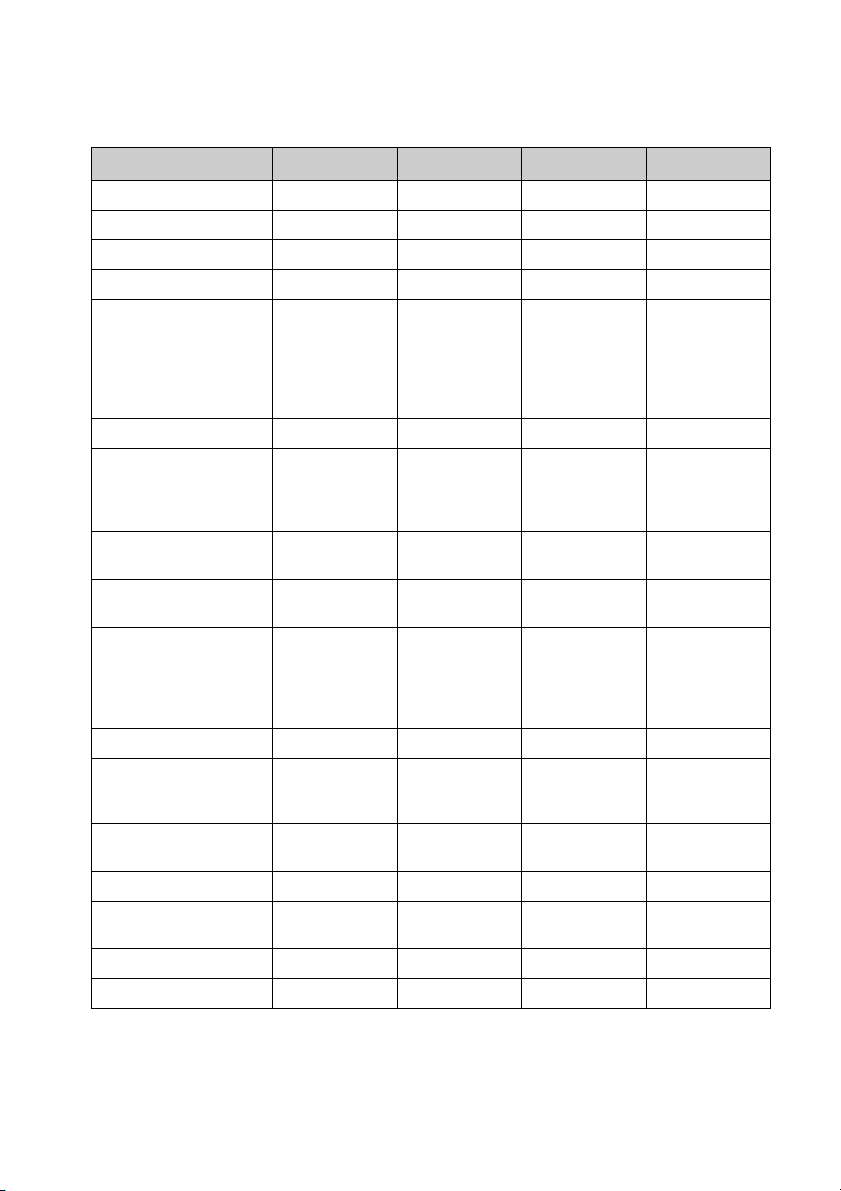

2. Technical data / Transport / Commissioning

2.1 Technical data

FRIAMAT

®

FRIAMAT

®

E FRIAMAT

®

L FRIAMAT

®

LE

Input voltage range AC 200 V.-. 260 V AC 200 V.-. 260 V AC 200 V.-. 260 V AC 200 V.-. 260 V

Frequency range 44 Hz... 66 Hz 44 Hz... 66 Hz 44 Hz... 66 Hz 44 Hz... 66 Hz

Current consumption AC 16 A max. AC 16 A max. AC 16 A max. AC 16 A max.

Power 3.5 kW 3.5 kW 3.0 kW 3.0 kW

Generator rated output 1~

d20 - d160 AC 2.4 kW AC 2.4 kW AC 2.4 kW * AC 2.4 kW *

d180 - d630 AC 4.0 kW AC 4.0 kW

(mechanical governor)

d180 - d630 AC 4.0 kW AC 5.0 kW

(electronic governor)

Equipment fuse 16 A slow acting 16 A slow acting 16 A slow acting 16 A slow acting

Casing Enclosure class Enclosure class Enclosure class Enclosure class

IP 54 DIN 40 050 IP 54 DIN 40 050 IP 54 DIN 40 050 IP 54 DIN 40 050

Protection class I Protection class I Protection class I Protection class I

DIN 57 700 DIN 57 700 DIN 57 700 DIN 57 700

Connection cable 5 m with 5 m with 5 m with 5 m with

contoured plug contoured plug contoured plug contoured plug

Fusion cable 4 m with Ø 4 mm 4 m with Ø 4 mm 4 m with Ø 4 mm 4 m with Ø 4 mm

fittings plug fittings plug fittings plug fittings plug

Bar code Code 2/5 Code 2/5 Code 2/5 Code 2/5

interleaved to interleaved to interleaved to interleaved to

ANSI HM 10.8M - ANSI HM 10.8M - ANSI HM 10.8M - ANSI HM 10.8M -

1983, ISO CD 1983, ISO CD 1983, ISO CD 1983, ISO CD

13950/08.94 13950/08.94 13950/08.94 13950/08.94

Working temperature range -20 °C ... +50 °C** -20 °C ... +50 °C** -20 °C ... +50 °C** -20 °C ... +50 °C**

Fusion current monitoring Short circuit 110 A Short circuit 110 A Short circuit 110 A Short circuit 110 A

Open circuit Open circuit Open circuit Open circuit

0.25 x I

N

0.25 x I

N

0.25 x I

N

0.25 x I

N

Printer interface Parallel - Parallel -

(D-Sub 25) (D-Sub 25)

Fusion voltage max. AC 48 V max. AC 48 V max. AC 48 V max. AC 48 V

Dimensions 370x280x480 mm 370x280x480 mm 350x260x450 mm 350x260x450 mm

W x D x H

Weight 19 kg 19 kg 14 kg 14 kg

Weight with transport box 23 kg 23 kg 18 kg 18 kg

*: The FRIAMAT®L / LE is only suitable for domestic connections and distribution pipes up to

d110, plus saddle components of all sizes

** : When fusing fittings from other manufacturers always take heed of the details given on the

working temperature range.