Instructions for movements

Movements are only permitted on perfectly flat and smooth

surfaces, and in the total absence of wind.

To move the mobile scaffold, the brackets must be lifted,

but not more than 12 millimetres.

Movements can only take place longitudinally or diagonally to

plan. With unilateral widening of the base with the wall support,

movement is only permitted if carried out parallel to the wall.

Mobile scaffold towers can only be manually moved and only on compact,

smooth surfaces free of obstacles.

Nobody or no objects must remain on the mobile platform during movement.

Furthermore, nobody must be within the range of one and a half times the height of the

mobile scaffold.

During movement, do not exceed walking speed.

Avoid all destabilising impacts, therefore pay attention to obstacles on the ground and in

the air. Always keep at least five metres from high voltage cables.

The surface on which the tower is moved must be capable of supporting the weight.

After each movement, braking and stabilising the mobile scaffold is

compulsory. Also check it is perfectly vertical.

It is forbidden to exceed 30 kg horizontal load

per person, pushing with work equipment, such as drills, etc.

Ladder Component Assembly

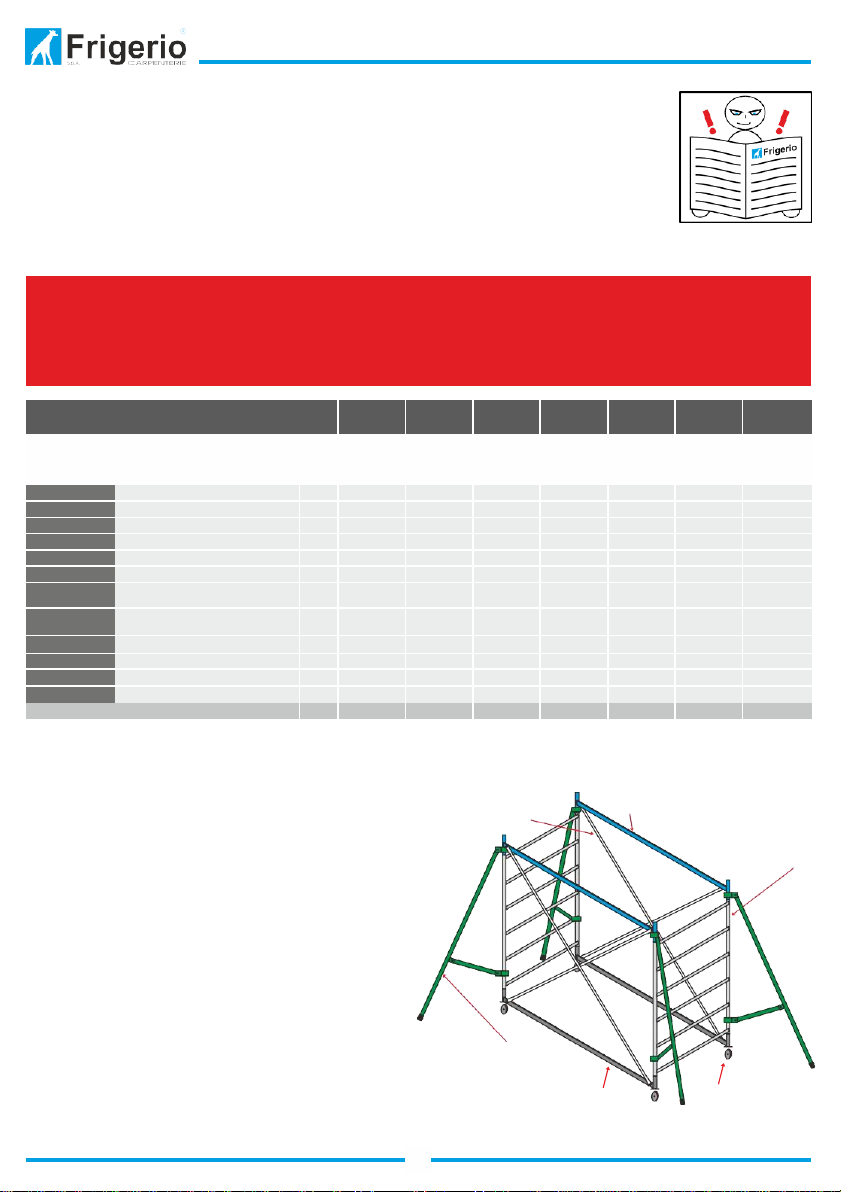

The ladder component (optional) allows you to work on seriously uneven surfaces, up to 80 cm, such as indoor

stairs. The component is composed of two legs with adjustable telescopic extension using a through pin.

The legs are fastened using the

specific clamps on the vertical

tubes of the base section and can

be orientated as necessary.

Firmly tighten the clamps on the

uprights of the support bar of the

base span (see drawing to side).

To ensure against vertical sliding,

the clamps must be fastened under

the horizontal crossbeams.

Level by sliding the telescopic tubes

and block them using the relevant

pins. Assemble the stabilising

brackets as per the configuration

used.

Note:

when the ladder component is being used, it is compulsory to anchor the mobile scaffold.