9

Part 1 - General Information

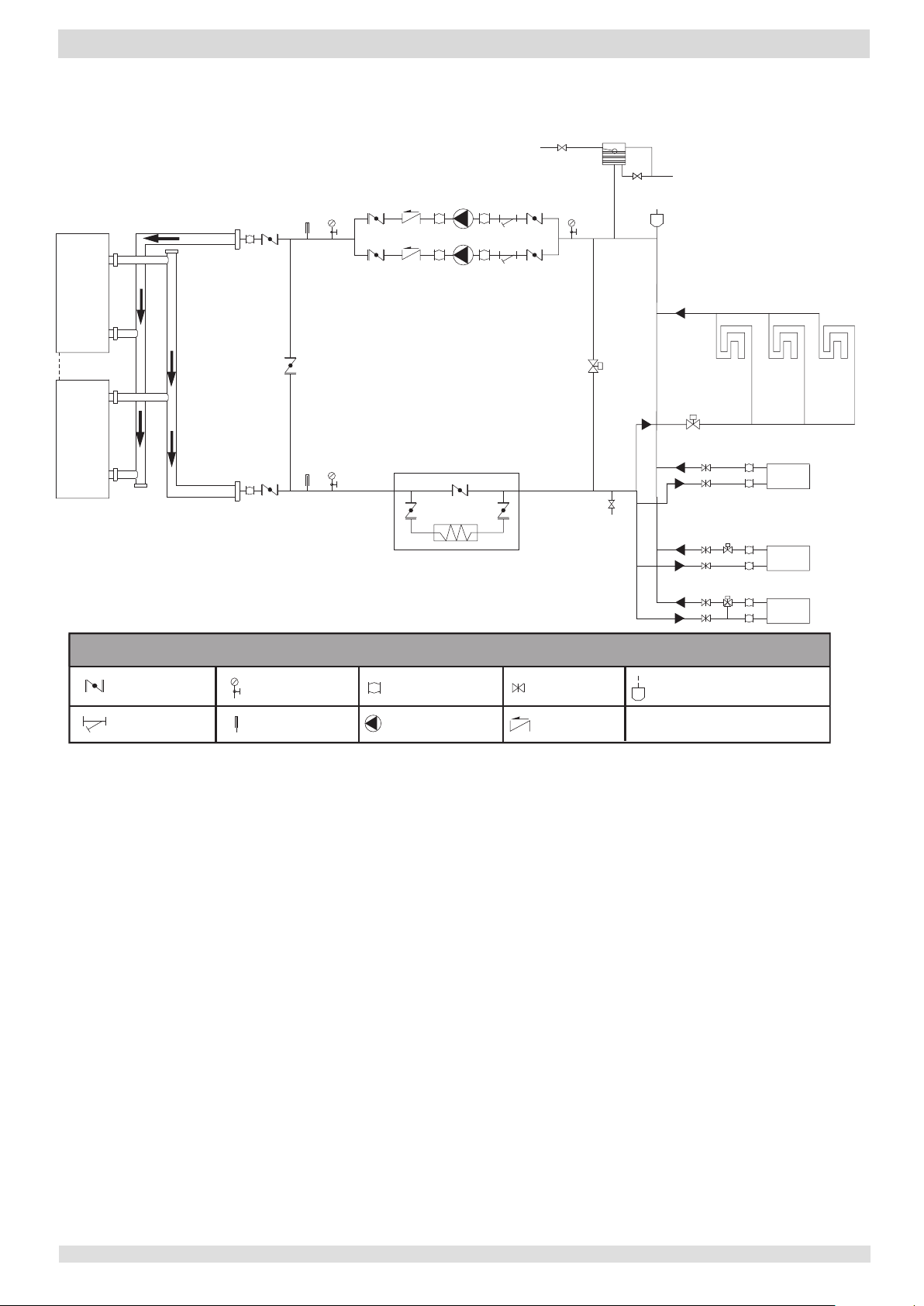

4 System Design And Unit Selection

4.1 Selection Procedure

Step 1: Total heat load calculation

Step 2: System configuration

Step 1: Total heat load calculation

Calculate conditioned surface area

Select the heat emitters (type, quantity, water temperature and heat load)

Decide whether to enable or disable auxiliary electric heater

Determine required total heat load on outdoor units

Set capacity safety factor

Select power supply

Provisionally select Aqua thermal Series unit capacity1 based on nominal

capacity

Correct capacity of the outdoor units for the following items:

Outdoor air temperature / Outdoor humidity / Water outlet temperature2 /

Altitude / Anti-freeze type

Is corrected Aqua thermal capacity ≥ Required total heat load on outdoor

units3

Aqua thermal system

selection is complete

Yes No

Notes:

1. Up to 16 units can be connected together, giving a system cooling/heating capacity range from 90kW to 1440kW.

2. If the required water temperatures of the heat emitters are not all the same, the Aqua thermal’s outlet water temperature setting should be set at the

highest of the heat emitter required water temperatures. If the water outlet design temperature falls between two temperatures listed in the outdoor

unit's capacity table, calculate the corrected capacity by interpolation.

3. Select Aqua thermal which satisfies both total heating and cooling load requirements.