1

ADVERTENCIA

1. Incorrect operation of this Liftgate can result in serious personal

injury. Comply with WARNINGS and Liftgate operating instructions

in this manual. Do not allow untrained persons or children to operate

the Liftgate. If you need to replace an Operation Manual, additional

copies are available from:

MAXON Lift Corp.

11921 Slauson Ave

Santa Fe Springs, CA 90670

(800) 227-4116

NOTE: For latest version manuals (and replacements), down-

load manuals from Maxon’s website at www.maxonlift.com.

2. Do not exceed rated load capacity of the Liftgate which is 2000 LB for

model TE-20, 2500 LB for model TE-25 and 3000 LB for model TE-

30.

3. Do not allow any part of your body to be placed under, within, or

around any portion of the moving Liftgate or its mechanisms, or in

a position that would trap them between the platform and the floor

of truck body (or between platform and the ground) when Liftgate is

operated.

4. Consider the safety and location of bystanders and location of

nearby objects when operating the Liftgate. Stand to one side of

platform while operating the Liftgate. Be certain that the area the

Liftgate will move through during operation is clear of all obstacles.

5. Comply with all attached instruction decals and warning decals.

11. Above all, USE GOOD COMMON SENSE when operating this

Liftgate.

8. Do not move vehicle unless Liftgate is correctly stowed.

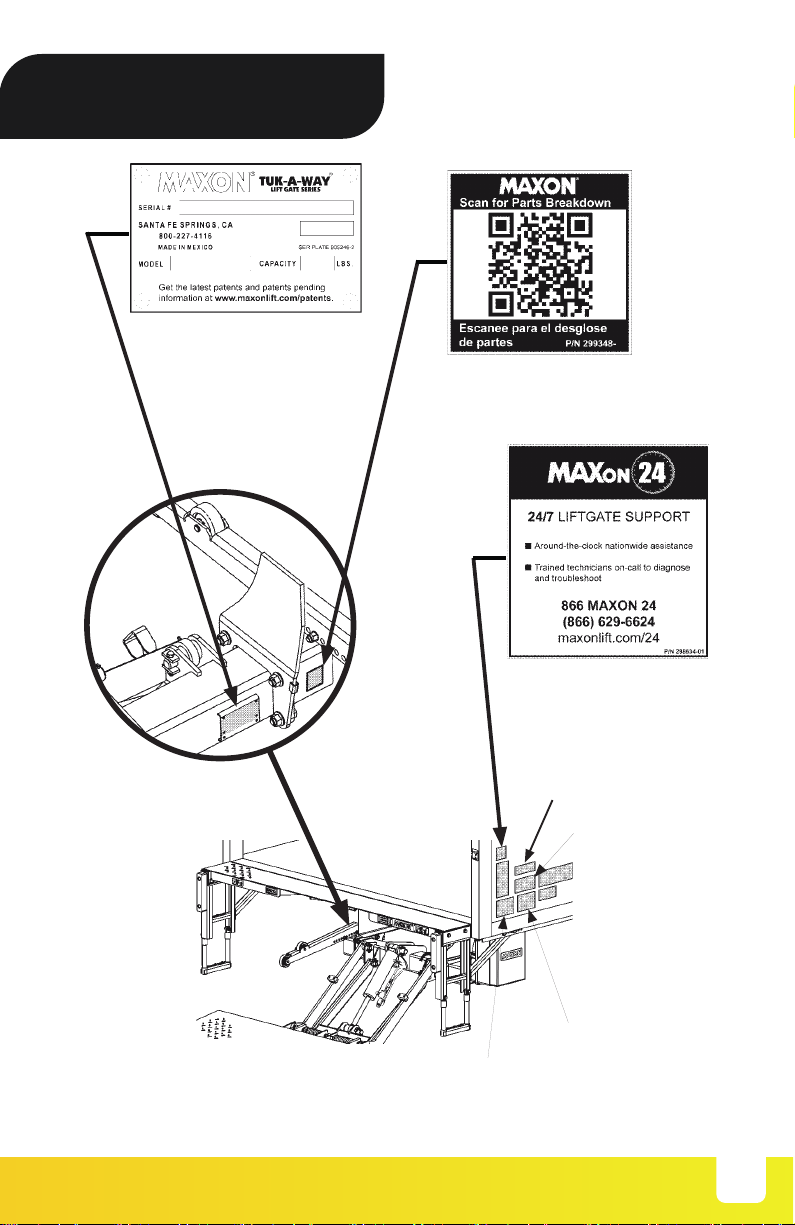

6. Keep decals clean and legible. If decals are illegible or missing,

have them replaced. Get free replacement decals from Maxon.

7. Never drive a forklift on the Liftgate platform.

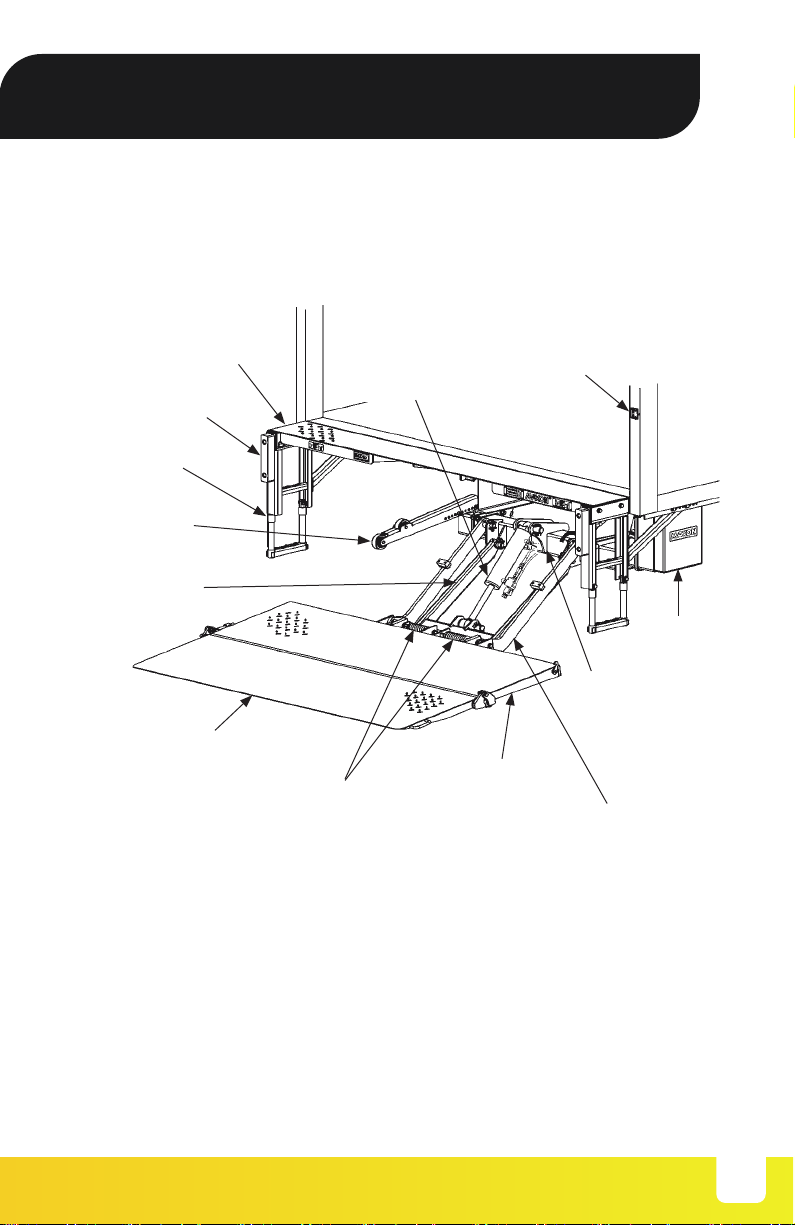

10. A correctly installed Liftgate will operate smoothly and reasonably

quiet. The only noticeable noise, during Liftgate operation, is from

the power unit while the platform is raised. Listen for scraping,

grating and binding noises and have the problem corrected

before continuing to operate the Liftgate.

9. Correctly stow platform when not in use. Extended platforms

could create a hazard for people and vehicles passing by.

12. Never use a cell phone while operating the Liftgate.