1

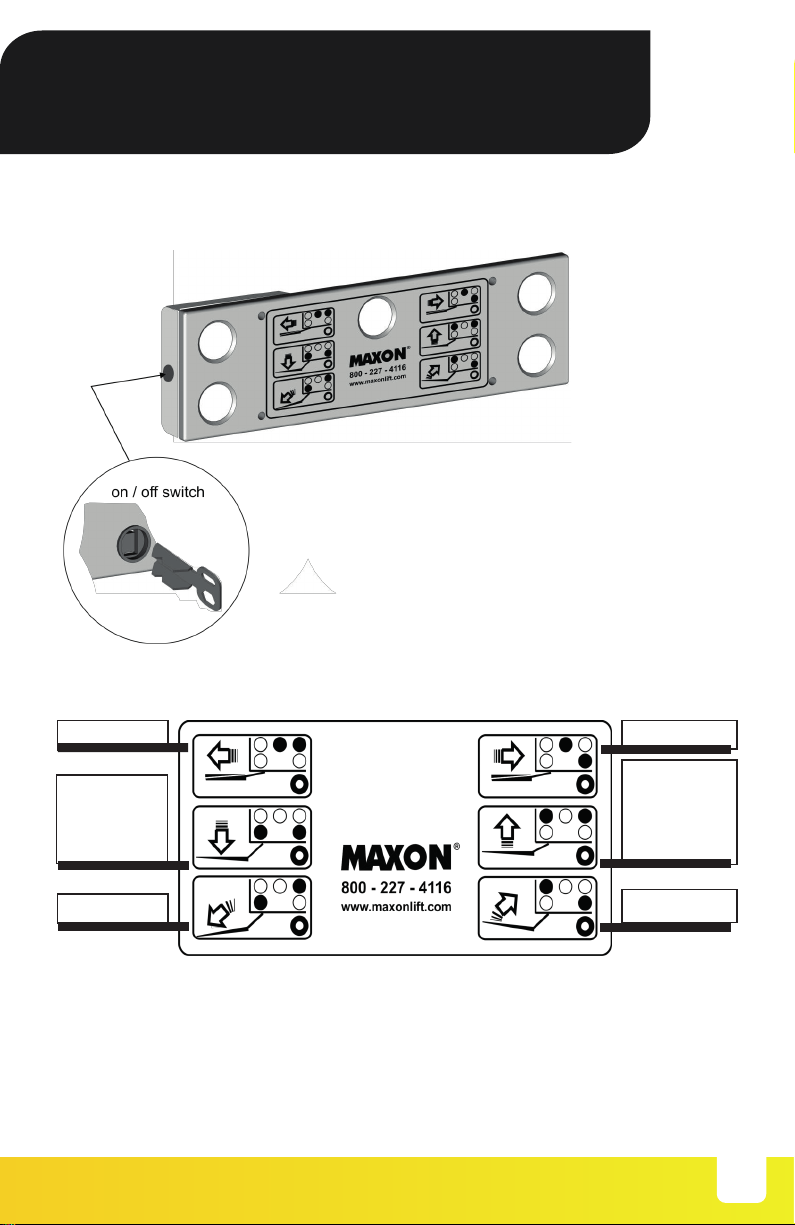

INFORMACIÓN GENERAL

General information

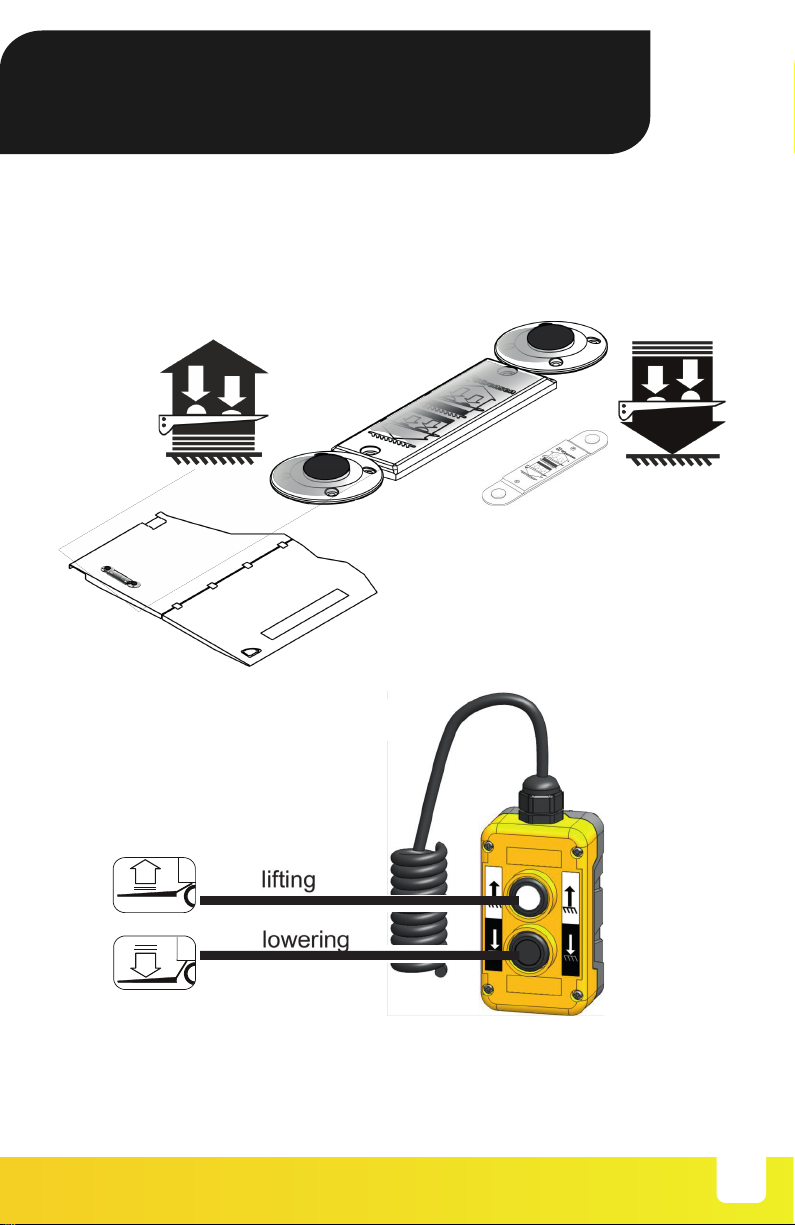

You have decided to purchase a top Slidelift. The Maxon Slidelift is very easy to use and to

maintain. It is equipped with maintenance and grease-free bearings, and does not require

greasing throughout its entire lifetime. The Maxon Slidelift is only to be used for lifting and lowering

of loads, which have to be placed on the platform in accordance with the loading diagram.

The Slidelift must only be operated, maintained and repaired by persons who have been

technically trained and who have especially been informed about the hazards that may occur

during operation. Otherwise, manufacturer's liability for resulting damages is void.

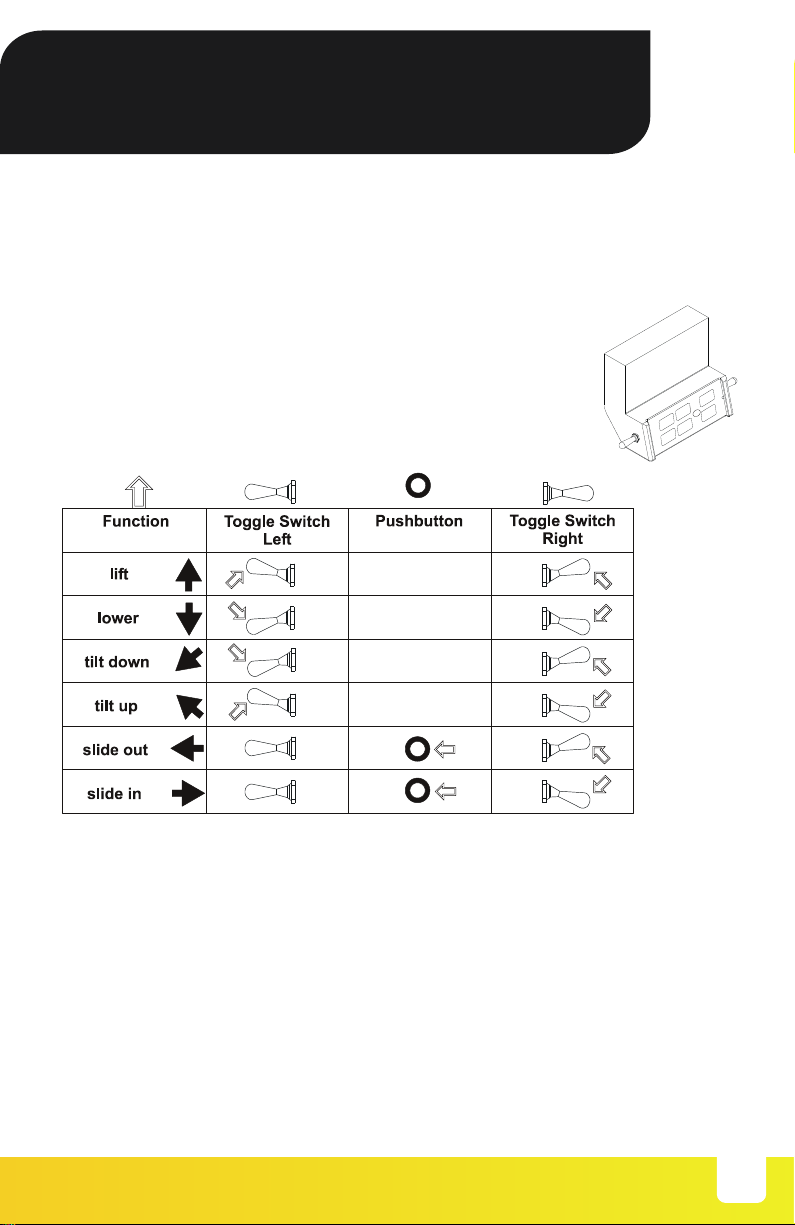

These operating instructions are valid for following lifts:

Daily verifications :

1. Function and completeness of all operating and security equipment

2. Legibility of all operating and information labels (replace if necessary)

3. Damages and completeness on bolts, bolt retainers, cracked or broken bolts and nuts

4. Damages and tightness of hoses, fittings and valves on hydraulic cylinders. Check all

hoses for leaks and tightness

5. Verify deformation of under ride device and energy absorber

6. Damages and function of platform warning lights

7. The function of the battery main switch (option) is to be checked

Recommended checks every month:

1. Check hydraulic fittings for tightness and tightening torque.

2. Check oil level.

If necessary correct with recommended oil.

3. Check wires and cables for damages.

Replace missing cable fasteners.

Correct if there are cutting and shearing risks.

4. Check hydraulic hoses for damages.

Replace missing fasteners.

Correct if there are cutting and shearing risks.

5. Check that al decals are in place and full readable.

Replace missing or damaged decals.

6. Check rubber seals at bearings.

Replace missing or damaged seals.

7. Check that all bearing pins are secured and without damage.

Replace if necessary.