Storage:

Keep the pump in a protected place and at the following climatic conditions:

- Temperature from: -20 °C to 40 °C

- Relative humidity from: 10% to 80%

- For higher humidity use an anti-rust oil on exposed parts

Warning

Use anti-rust oil with fire point over 200 °C

Warning

Dispose the used anti-rust oil in accordance with local regulations.

INSTALLATION

Warning

THE PUMP IS DELIVERED WITHOUT OIL. OIL MUST BE ADDED TO THE PUMP PRIOR TO OPERA-

TION. USE SYNTHETIC EP 220 OIL.

QUALIFIED PERSONNEL

Only qualified and trained personnel who are familiar with the FRUITLAND products should work on, repair

or operate the pump. Original parts supplied by or approved by FRUITLAND must only be used for repair and

main-tenance. Failure to comply with the instructions provided in this manual, may lead to the following

dangers:

- Increased temperature rise beyond the safe operating temperature of the pump and as a burning hazard.

- Danger due to the shaft rotation and other mechanically moving parts.

- Noise generated beyond acceptable limits - hearing protection must be worn in close proximity to the pump.

- This pump is suitable only for applications as described in this manual. Other applications must be approved

by the factory.

If the pump is placed on an irregular base, before tightening it to the frame, check that all four feet touch the

base properly and, if need, use appropiate shims.

The drivetrain coupling or belts must be installted as prescribed by their respective manufacturers.

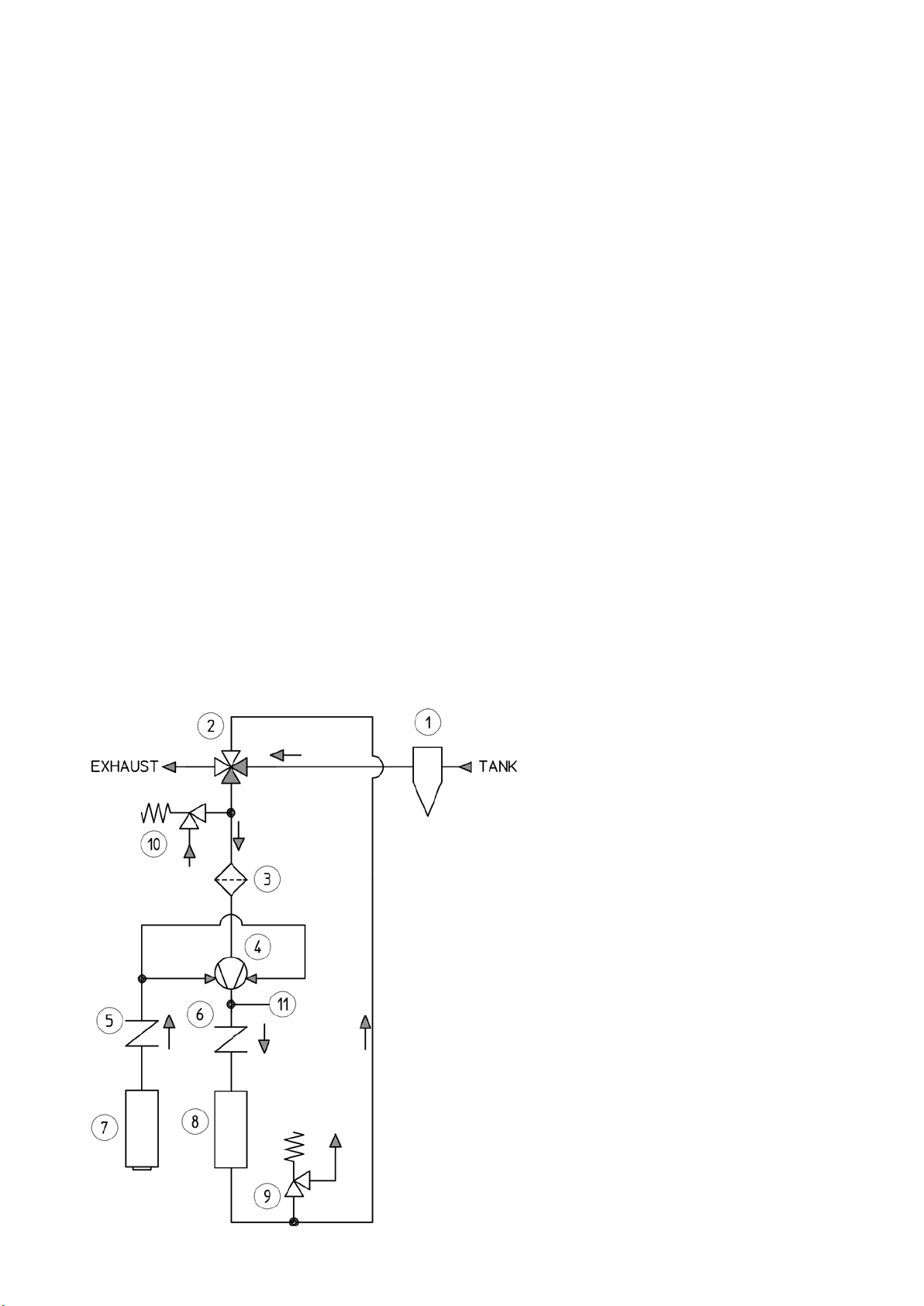

Under no circumstances must liquids, dust or any kind of solid matter enter the pump. If this happens it will

likely cause catastrophic failure of the pump. It is necessary to protect the pump with appropriate safety

valves and filters. The pump must be used for the purpose for which it was designed. Any other uses must

be approved by the factory.

Don not use this pump to handle flammable gas or liquids. Contact FRUITLAND for special

applications. Never remove safety guards or filters. Check all guards and filters every time prior to operating

the pump.