II. Mounting

When mounting the system on a wall, mark out the approx. location of each wall bracket. Fix a bracket to

the wall and using a level and ruler, mark out the appropriate location for the second bracket. Brackets

should ideally have the pivot/hinge at the bottom and screw to close the bracket at the top. Hold the

Chamber in firmly to the brackets and they do up one of the clamps to secure the system. A second set of

hands can assist to make this easier.

III. Installing Connections

The UV systems are manufactured with male BSP threads either in 1” (GT7-8K) or ½” (GT7-4K). The

smaller GT7-2K unit is ¼” Female. Use appropriate plumbing fittings to install onto the chamber for

adapting to your plumbing.

IV. Filter Protection

As per Australian Plumbing Codes, a pressure limiting valve should be installed to limit the pressure to 500

kPa when the feed pressure exceeds 500 kPa. If Water Hammer is present, install a suitable Water

Hammer Arresting device.

Commissioning & Start-up

I. Quartz Thimble Installation

Due to the fragile nature of the quartz, care must be taken when handling and installing the thimble and

lamp. The below steps are for horizontal installations.

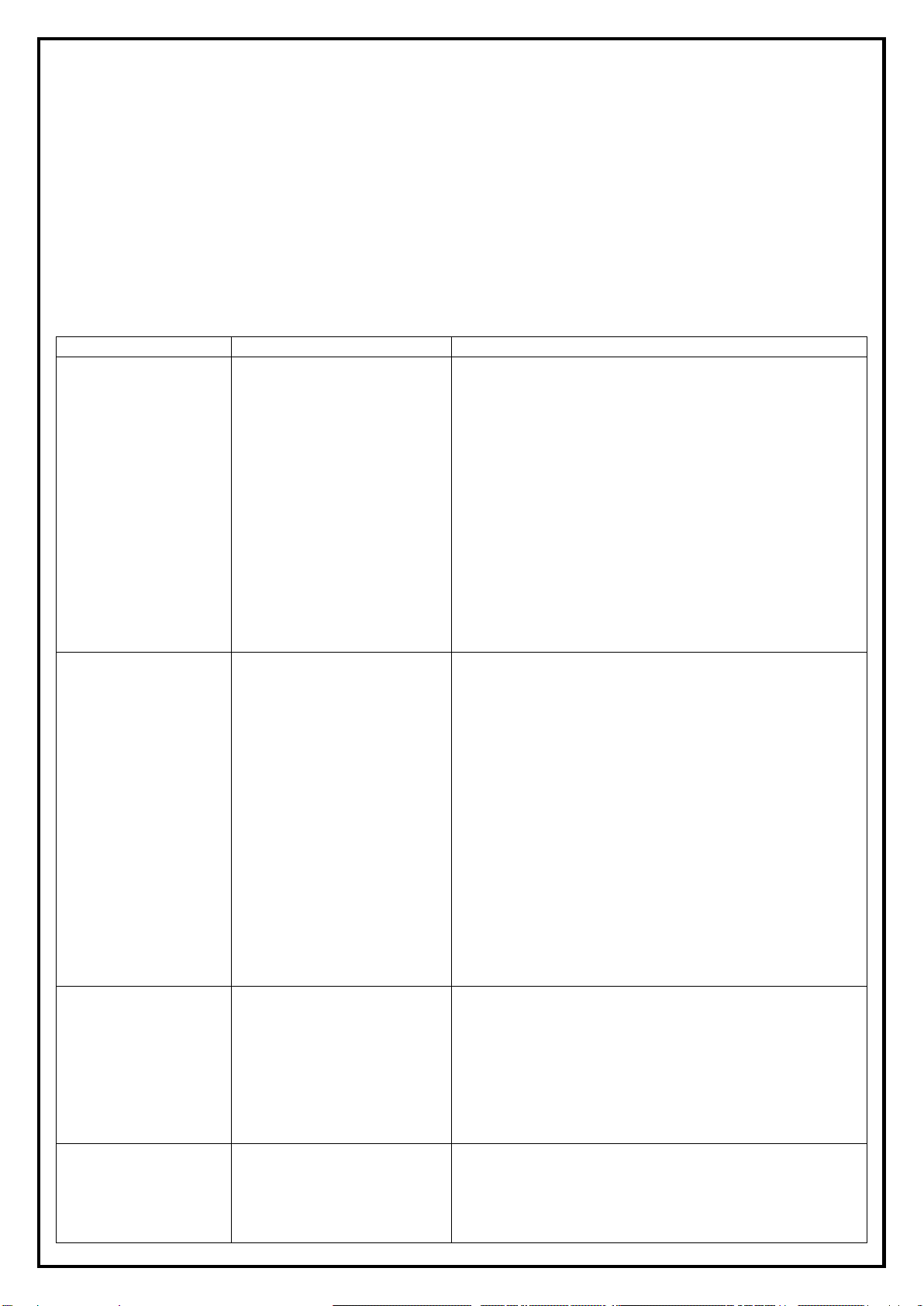

1. Remove the knurled nuts from either end of the SS chamber.

2. Wearing clean gloves or handling using a micro-fibre cloth, remove the thimble from the packaging

and check for any marks or blemishes. Insert the glass thimble into the chamber at the open end.

The thimble will need to go into the chamber by the domed end first. Centre the thimble in the

chamber so there are equal parts protruding from either end of the SS chamber.

3. Place an o-ring over each end of the glass thimble and seat the o-ring firmly against the thread as

shown beside.

4. The closed knurled nut is to go on the domed end and the open knurled nut goes at the open end of

the thimble. Loosely screw on both nuts until you feel resistance. Then simultaneously tighten both

nuts by hand until it is firmly hand tight. NOTE: Firmly hand tightening is sufficient to seal these

chambers without the use of tools – Do NOT apply thread tape or sealant glue to the end threads.

Caution: Overtightening the end nuts may cause the glassware to crack.

5. You can look through the open end of the nut to see if the o-ring is seated correctly. There will likely

be a slight gap between the end edge of the thimble and the recessed stop end of the knurled nut,

this is normal in most cases. If however there is no gap and the thimble is pressed hard up against

the stop end in the knurled nut, either the fittings are too tight OR the domed end of the thimble has

been pushed back inwards which causes the open end to protrude out of the chamber too far. If this

is the case, loosen the domed end and adjust the thimble position.

From this point, the water supply should be turned on to pressurise the chamber and identify if there are

any leaks from the plumbing connections or from the thimble. If leaking occurs from the thimble, it is

possible that it may only be a slow beading leak which will need to be rectified before installing the lamp.

For vertical installations, it is extremely important that there are no slow leaks as over time these will fill up

the thimble with water and cause a short in the lamp which can result in injury or damage to the lamp &

ballast which is not covered under warranty.

If any water is present on the thimble or chamber from the installation process, it will need to be thoroughly

dried before continuing with the installation.

II. Installing the UV Lamp

When, and only when the chamber and thimble are deemed to be water tight and free from leaking can the

lamp be installed. Handle the lamp only by the plastic end caps and support it by both ends.

1. Remove the lamp from its protective wrapping