Thank you for your purchase.

Thank you for purchasing this Fu Sheng Co., Ltd product.

To ensure safe and efficient use, please install and operate this equipment in

accordance with the instructions provided in this manual.

Product specifications are subject to change without notice. Please be aware that

recent changes to product specifications may not be reflected in the content of

this manual.

CONTENTS

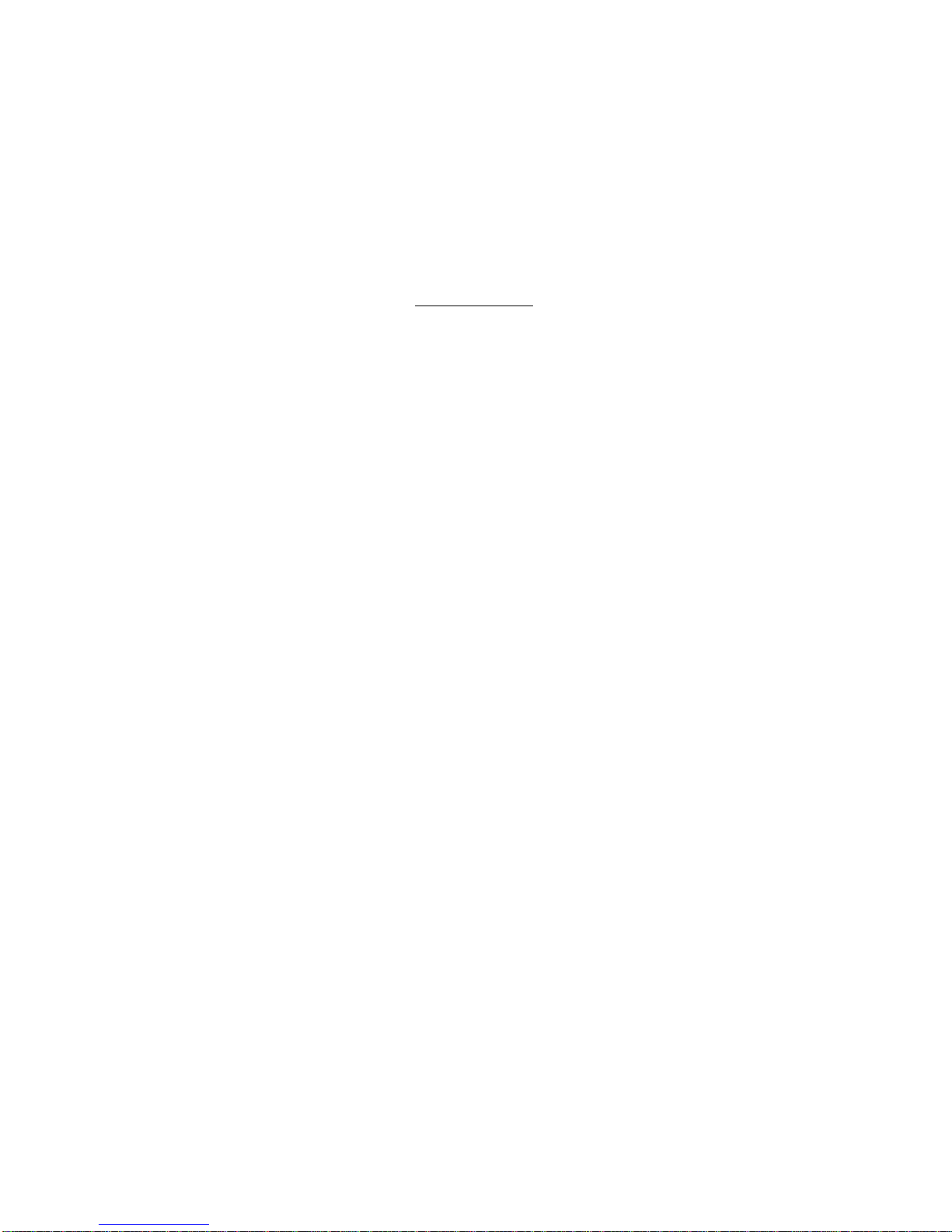

Important Notes...................................................... 1(1)

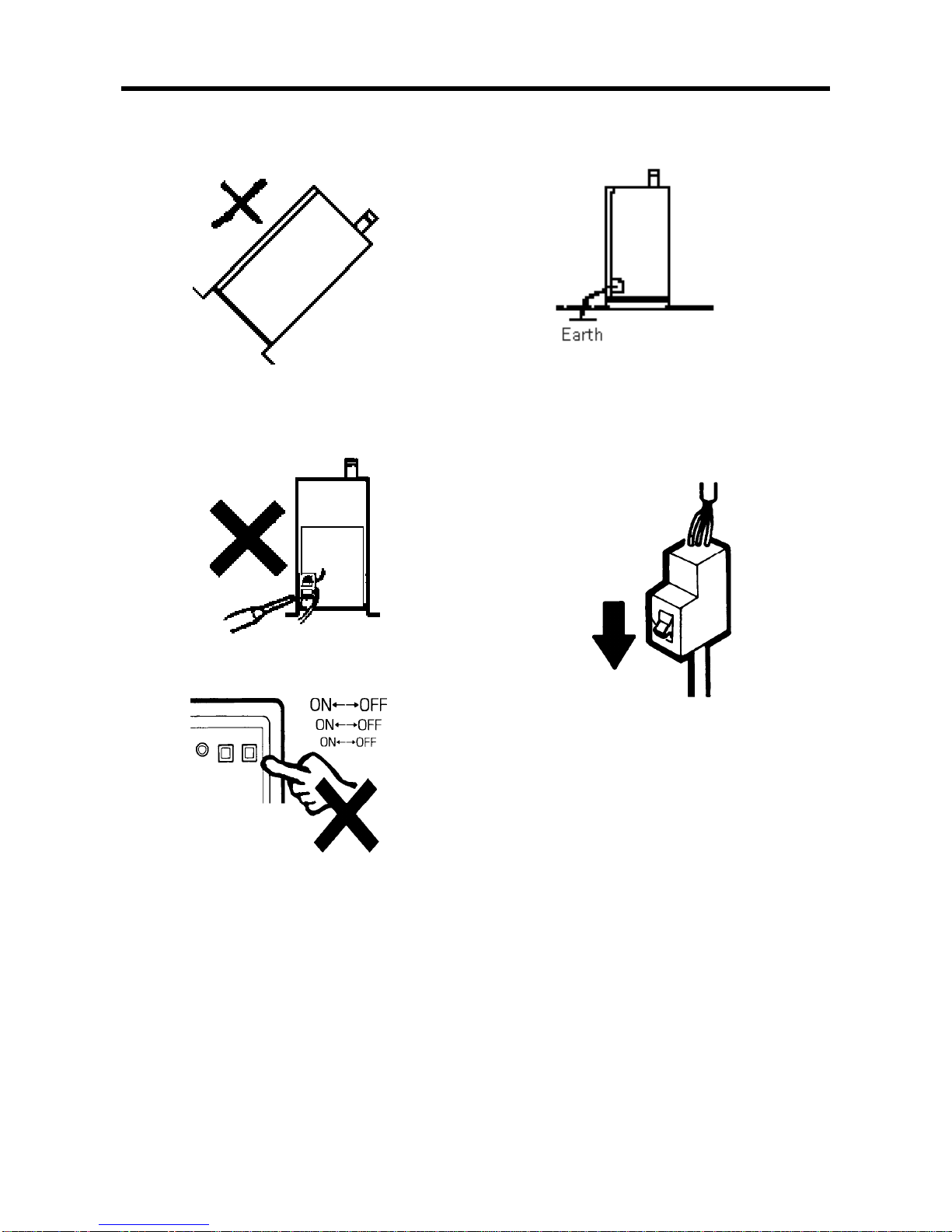

Names of Parts and Functions.......................................... 2(1)

1.Appearance.................................................. 2(1)

2.Control panel................................................ 2(1)

3.Switch board................................................. 3(1)

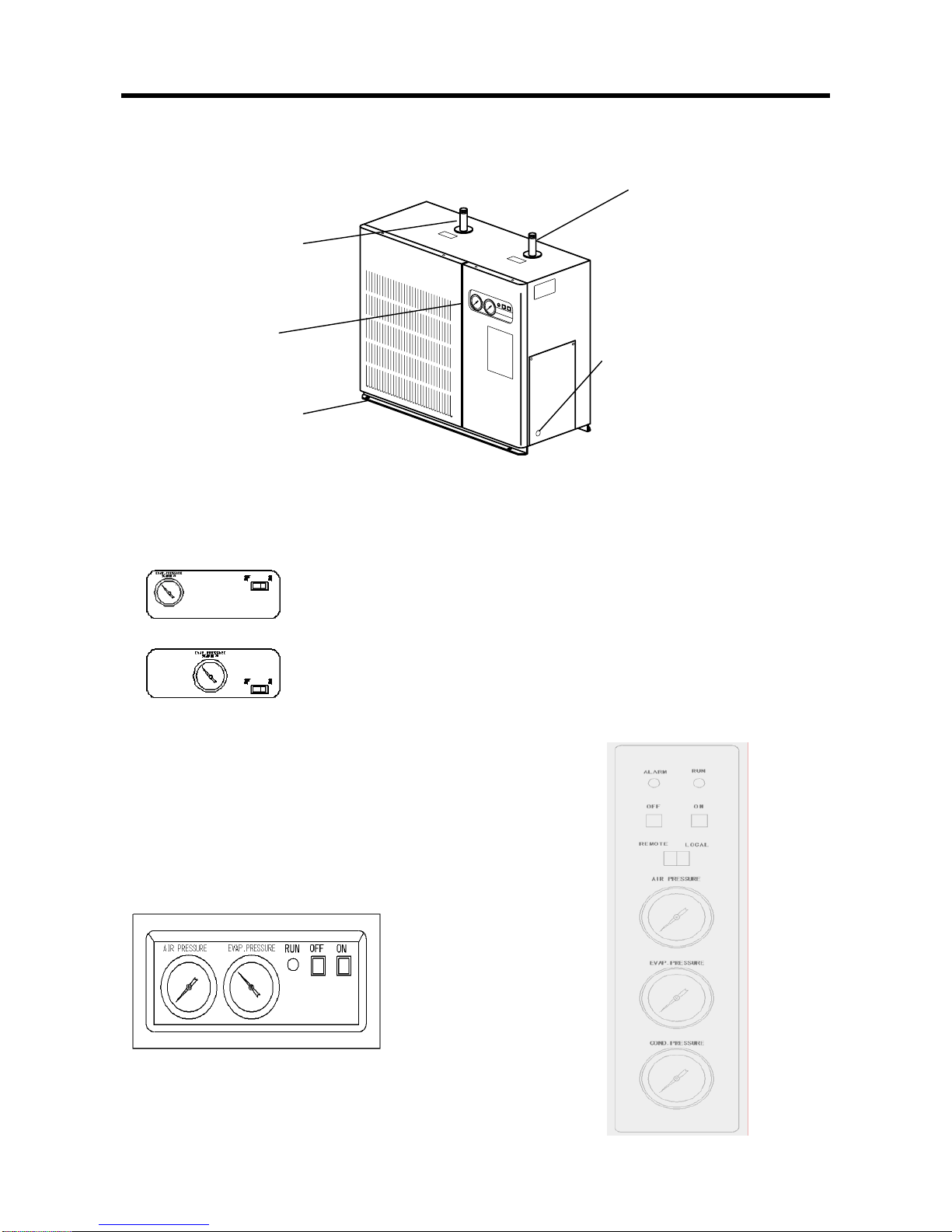

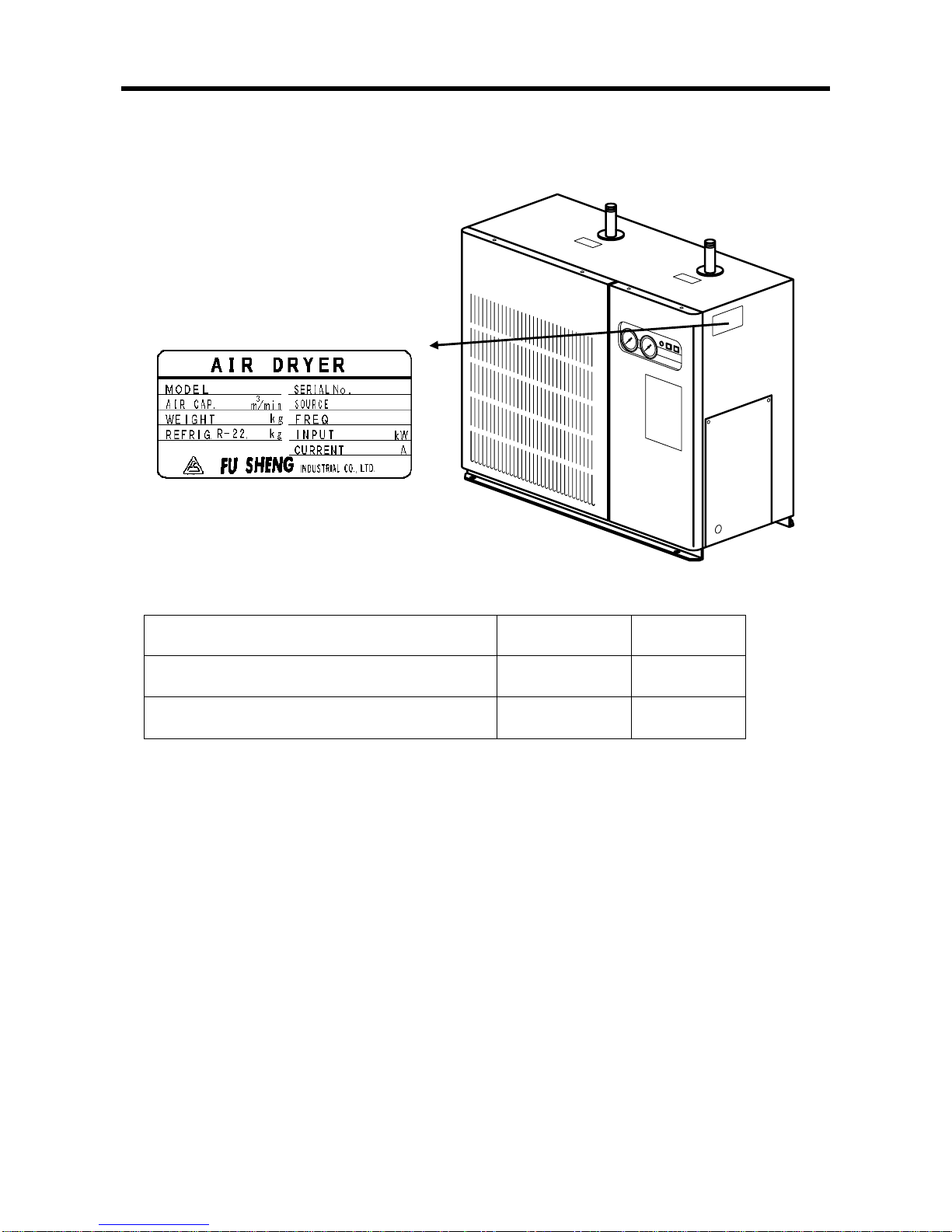

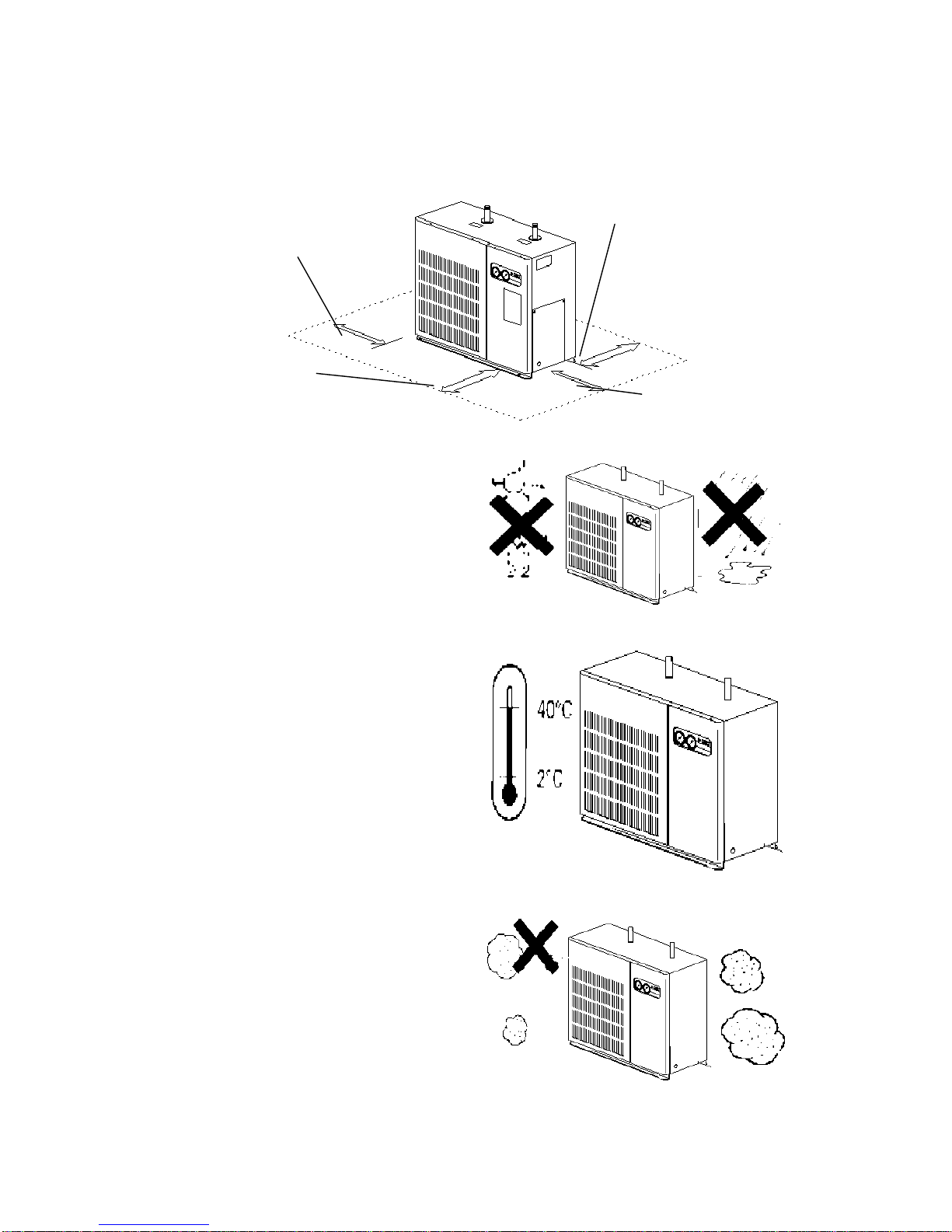

Installation Notes..................................................... 4(1)

1.Checking Model.............................................. 4(1)

2.Space for Installation.......................................... 5(1)

3.Forbidden places.............................................. 5(1)

Preparation for Operation............................................. 6(1)

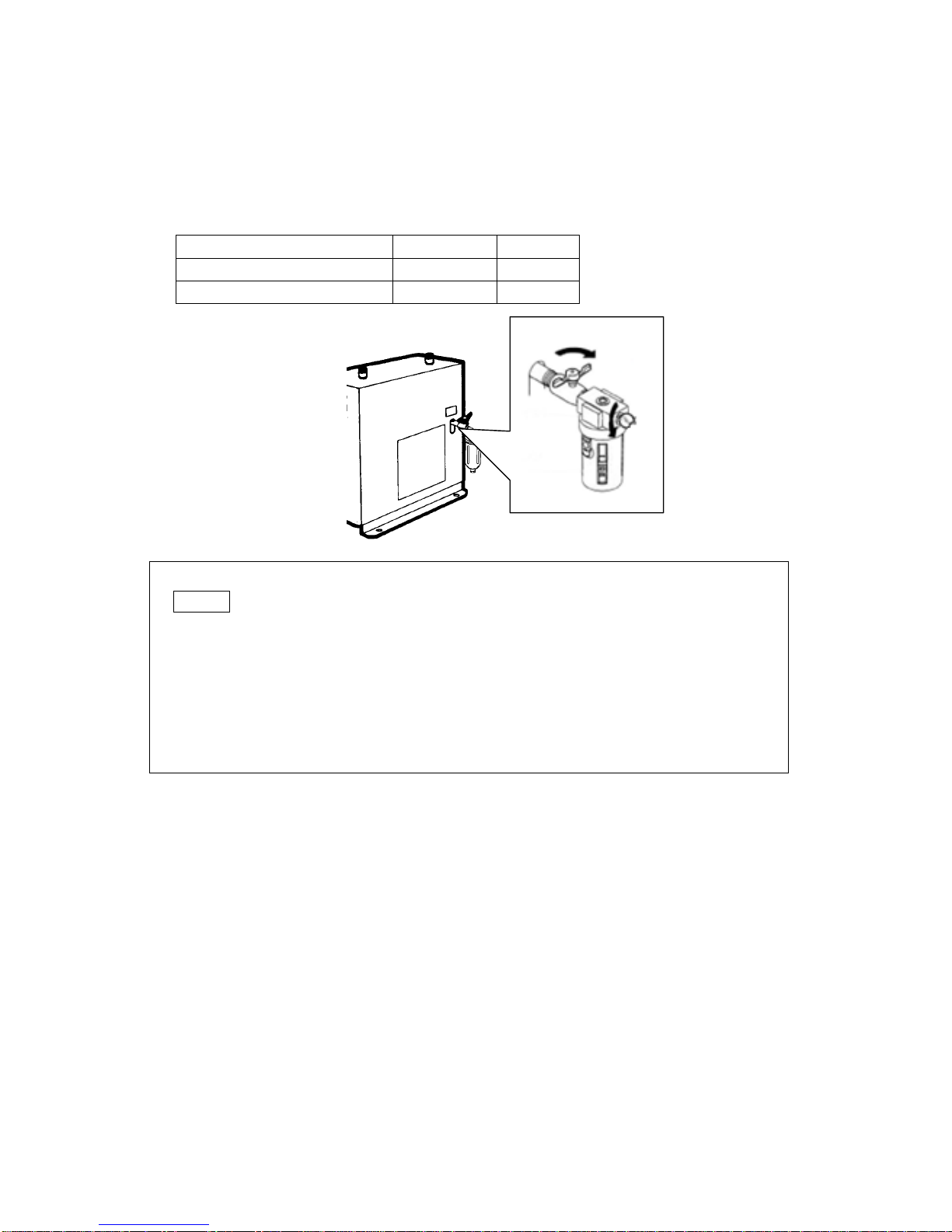

1.Piping....................................................... 6(1)

2.Installation of Accessories....................................... 7(1)

3.Wiring........................................................ 9(1)

Operation............................................................ 10(1)

1.How to Start.................................................. 10(1)

2.How to Stop.................................................. 11(1)

Safety Devices......................................................... 12(1)

Daily Maintenance and Checks........................................... 13(1)

1.Daily Checks................................................... 13(1)

2.Maintenance................................................... 13(1)

1)Cleaning of Condenser...................................... 13(1)

2)Cleaning of Auto Drain Trap(ET3000 4000).................... 14(1)

3)Cleaning of Auto Drain Trap(AD-5).......................... 15(1)

Troubleshooting....................................................... 16(1)

After-Sale Service.................................................... 16(1)

Before Long Disuse.................................................... 17(1)

Table of Specifications.................................................. 18

Specification.......................................................... 20

Part list............................................................. 30