Fujitsu AS G07KGTB Series Original operating manual

Other Fujitsu Air Conditioner manuals

Fujitsu

Fujitsu AIRSTAGE AUXS018GLEH User manual

Fujitsu

Fujitsu ARHG12LLTB User manual

Fujitsu

Fujitsu AIRSTAGE V-II User manual

Fujitsu

Fujitsu ASYG-14LMCA User manual

Fujitsu

Fujitsu ASU9RL2 Service manual

Fujitsu

Fujitsu AIR CONDITIONER DUCT TYPE User manual

Fujitsu

Fujitsu ARY12LUAD User manual

Fujitsu

Fujitsu ASY20MI-KM User manual

Fujitsu

Fujitsu AOUG09LZAH1 Service manual

Fujitsu

Fujitsu AST24PBA User manual

Fujitsu

Fujitsu ABYF24LAT User manual

Fujitsu

Fujitsu AS G09LLCC Series Original operating manual

Fujitsu

Fujitsu AGYG12KVCB Service manual

Fujitsu

Fujitsu Inverter ARTG12LL User manual

Fujitsu

Fujitsu Airstage VR-II ARUM24TLAV User manual

Fujitsu

Fujitsu AUXG36KRLB User manual

Fujitsu

Fujitsu ABYG18LVTB User manual

Fujitsu

Fujitsu AU Series A12LAL User manual

Fujitsu

Fujitsu UTZ-KXGC User manual

Fujitsu

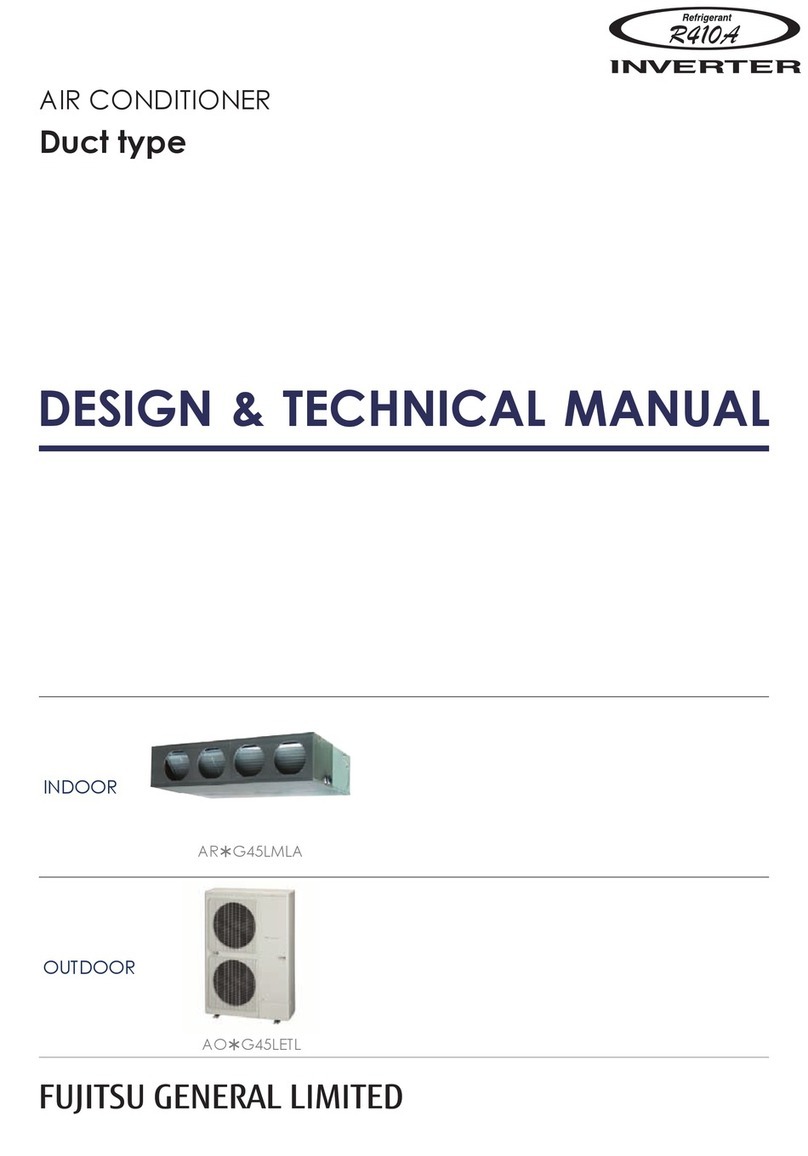

Fujitsu AR G45LMLA Series Service manual

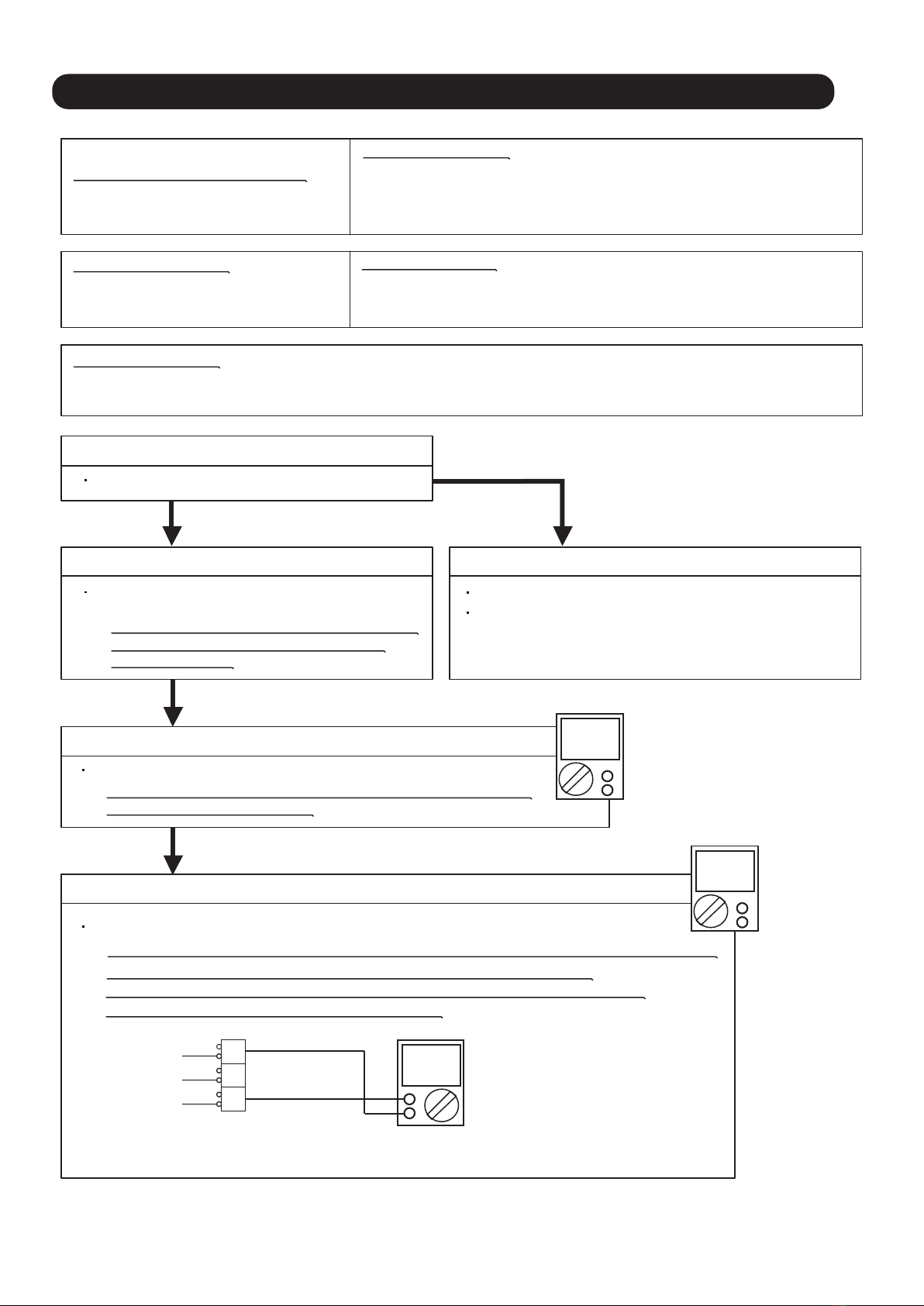

Popular Air Conditioner manuals by other brands

Webasto

Webasto Frigo Top 25 DS Instructions for use

Frigidaire

Frigidaire FAZ12ES2A installation instructions

Mitsubishi Electric

Mitsubishi Electric MSC-GE20VB operating instructions

Mitsubishi Electric

Mitsubishi Electric PLA-M100EA installation manual

Daikin

Daikin Split Sensira R32 Service manual

Carrier

Carrier 42HVM109303 Service manual