- (01-04) -

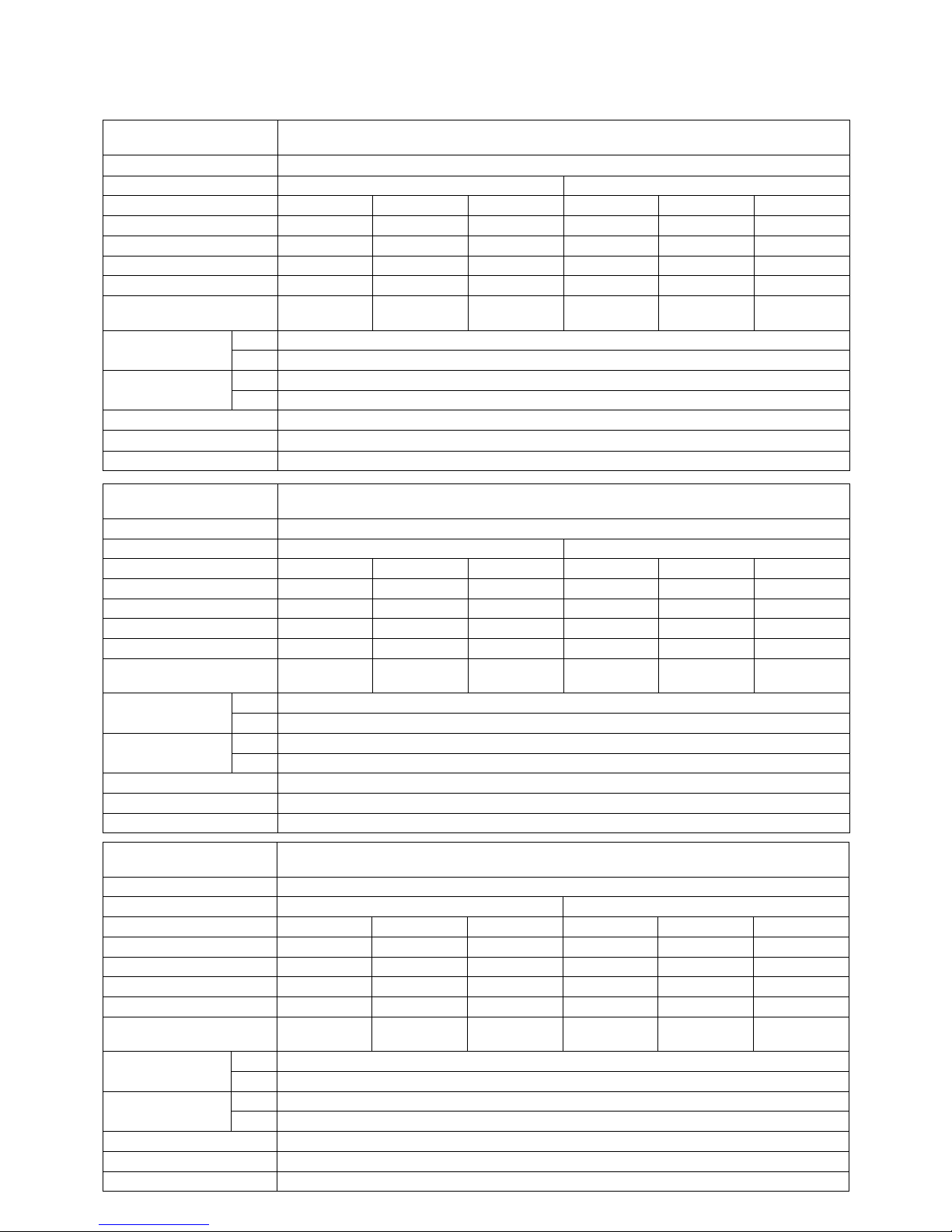

SPECIFICATIONS

Model

No.

Power

Source Notch Frequency

Heat Exchange Ventilation Normal Ventilation

Product

Weight

Input Current Air

Volume

External

Static

Pressure

Temperature

Exchange

Efciency

Enthalpy

Exchange

Efciency (%)

Noise Input Current Air

Volume

External

Static

Pressure

Noise

(Hz) (W) (A) (m3/h) (Pa) (%) Cooling Heating (dB) (W) (A) (m3/h) (Pa) (dB) (kg)

UTZ-

BD025B

220-240V

a.c.

Extra High

50 112-128 0.51-0.53 250 105 75 63 70 30.0-31.5 112-128 0.51-0.53 250 105 30.0-31.5

29

High

50 108-123 0.49-0.51 250 95 75 63 70 29.5-30.5 108-123 0.49-0.51 250 95 29.5-30.5

Low

50 87-96 0.40-0.41 190 45 77 65 72 23.5-26.5 87-96 0.40-0.41 190 45 23.5-26.5

This noise of the product is the value which was measured at the acoustic room. Actually, in the established condition, that undergo inuence

by the echoing of the room and so that become bigger than the display numerical value .

PERFORMANCE

Use conditions

Outdoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Indoor air conditions

Temperature range -10˚C ~ 40˚C

Relative humidity 85% or less

Installation requirements

Same as the indoor air conditions

*

Indoor air here means air in air-conditioned

living rooms.

Its use in refrigerators or other places

where temperature can uctuate greatly is

prohibited even if a temperature range is

acceptable.

Example Indoor air conditions

During cooling period

Temperature 27˚C

Relative humidity 50%

During heating period

Temperature 20˚C

Relative humidity 40%

• The Input, the current and the exchange

efficiency are values at the time of the

mentioned air volume.

• The noise level shall be measured 1.5m

below the center of the unit.

• The temperature exchange efficiency

averages that of when cooling and when

heating.

MOTOR

SPECIFICATIONS

Type 4 Poles open type

induction motor

Rating Cont.

Insulation Class class E

Temperature Rise under 75 K

Sorrounding Temperature

-10˚C ~ 40˚C

Insulation Resistance

over 1MΩ (by DC500V)

Withstand Voltage AC 1,500V for 1min

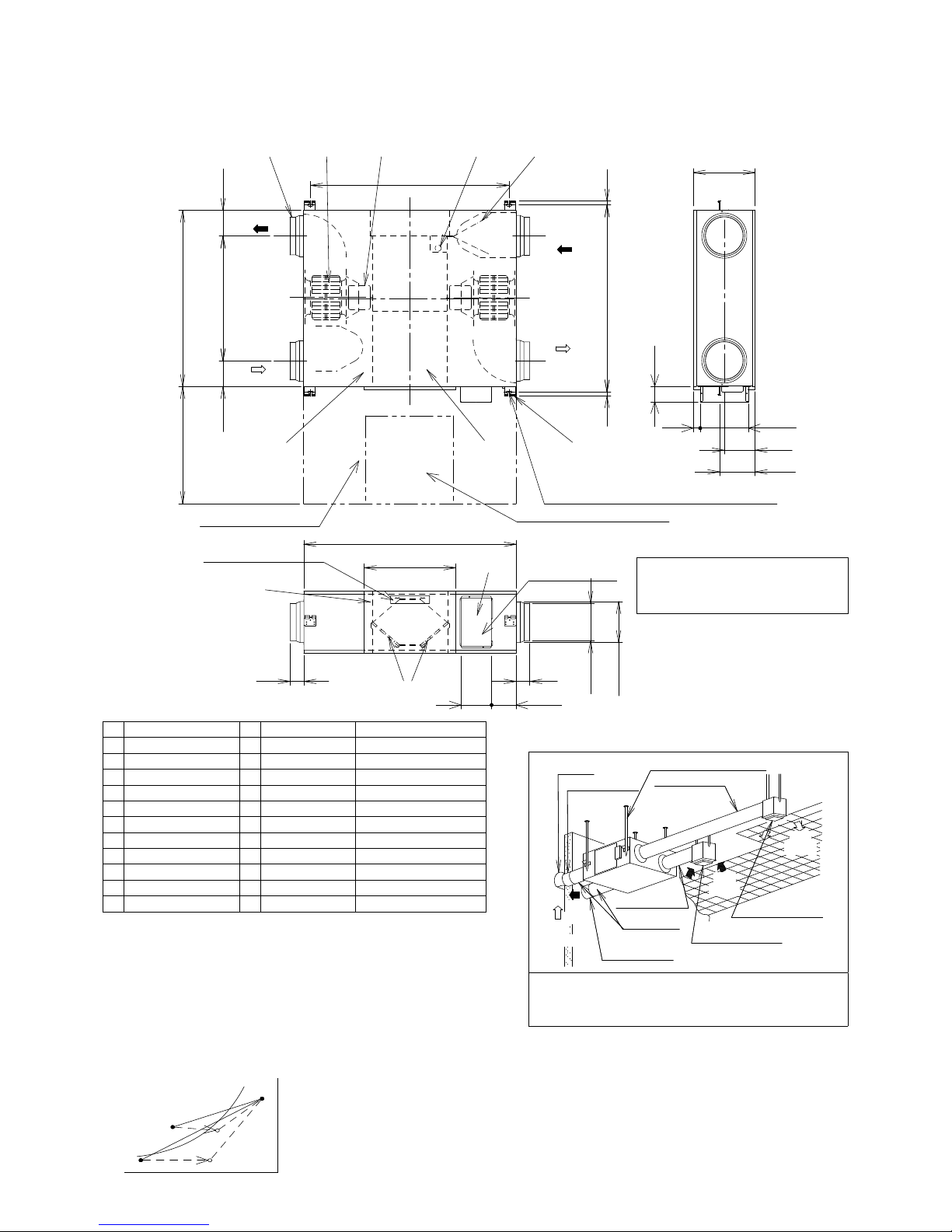

300

0 50 100 150 200 250 300 350

50

100

150

200

250

0 20 40 60 80 100 120 140 160 180 200 220

Air Volume (m3/h)

Air Volume (ft3/min)

External Static Pressure (Pa)

80

50

60

70

Exchange Efciency (%)

Duct resistance Curve

P-Q Curve

220 - 240V ~ 50HzEfciency Curve

T

e

m

pe

ra

t

u

r

e

E

nt

h

al

p

y

(i

n

h

e

a

t

i

n

g

)

E

nt

h

al

p

y

(i

n

c

o

o

li

n

g

)

Extra High

Equivalent pipe length

High

Low When friction coefcient of pipe (duct) : =0.02

100m

80

60

20

40