EN

6

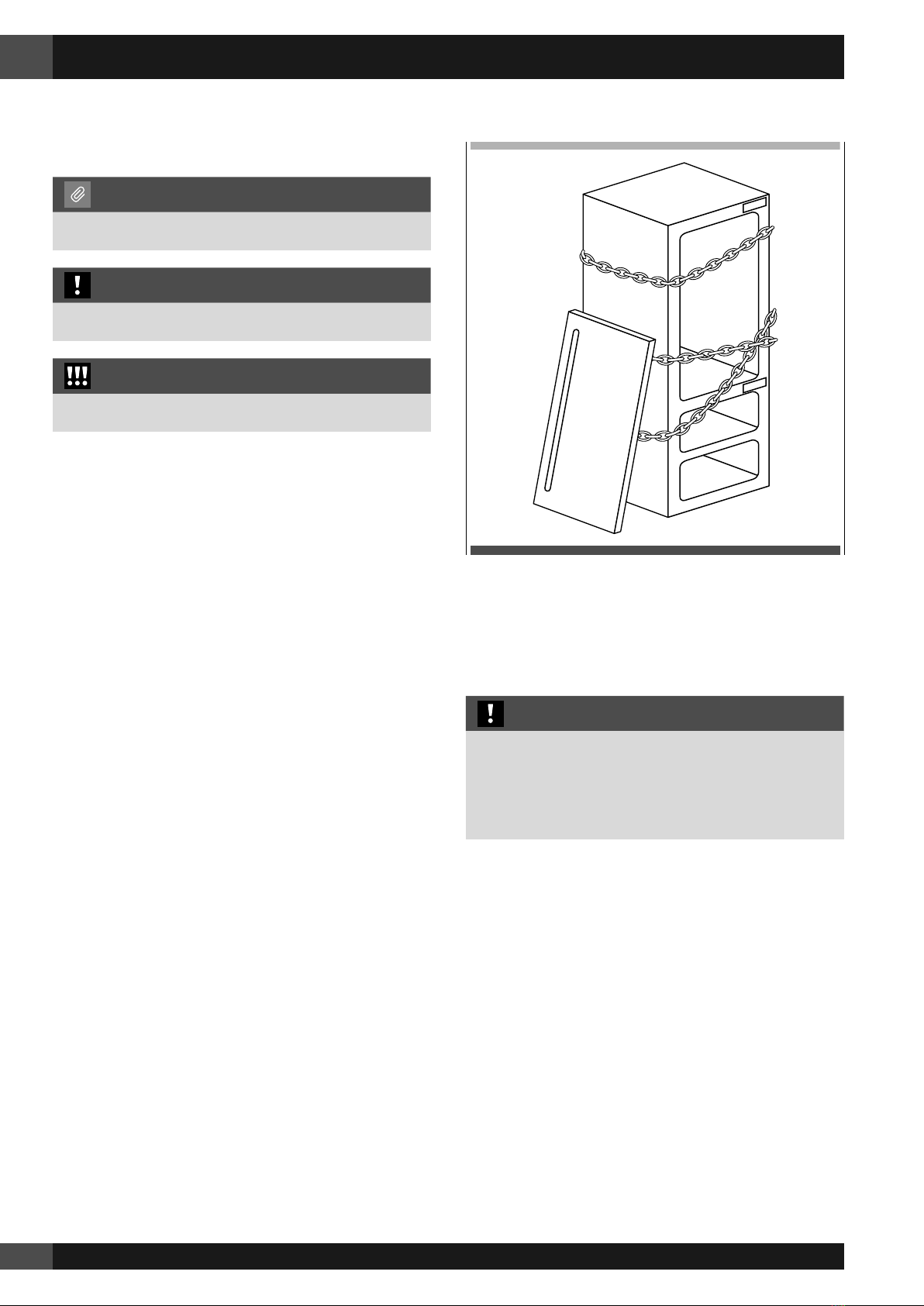

3.1 Transport to installation site and unpacking

WARNING

The appliance is very heavy.

Take maximum care during handling to avoid injury.

IMPORTANT

The appliance should always be transported in an erect

position.

Avoid at all costs leaning it on its front side.

1

4

1

2

3

Since this is a large and heavy appliance, before

transporting the appliance, check the access to the location

where it will be installed (door size, manoeuvring space in

stairwells, etc.).

The appliance is attached to the base of the packaging

(pallet) through four bolts which can be removed using a 19

mm (3/4”) wrench.

It is recommended to use a manual transporting device to

move the appliance to the installation site, and only at this

point to remove the base of the packaging.

The appliance should always be transported in an erect

position.

If this is not possible, transport the appliance laying on its

rear side.

Once at the installation site, the appliance, which is

equipped with four wheels, can be taken off the pallet and

positioned in the installation area.

Operate as follows:

• Take off the four bolts securing [ 1 ] the appliance to the

pallet by means of a 19 mm (3/4”) wrench or socket.

• Remove the fixing brackets [ 3 ] and [ 4 ].

• To release the front fixing bracket [ 3 ], unscrew the rear

wheel adjusting bolt [ 2 ] by means of a 13 mm (1/2”)

wrench or socket. Avoid straining this bolt at its stop

points one way or the other so as to not damage the rear

leveling system.

Ensure the front leveling legs are retracted so that

all 4 wheels are able to contact the floor for easiest

maneuvering.

• From the back of the unit and by means of a suitable,

high duty hand trolley, take off the appliance and place

it on the floor.

Be very careful to avoid any damage to floors. Delicate

floors should be protected with plywood, hard cardboard

or similar material panels.

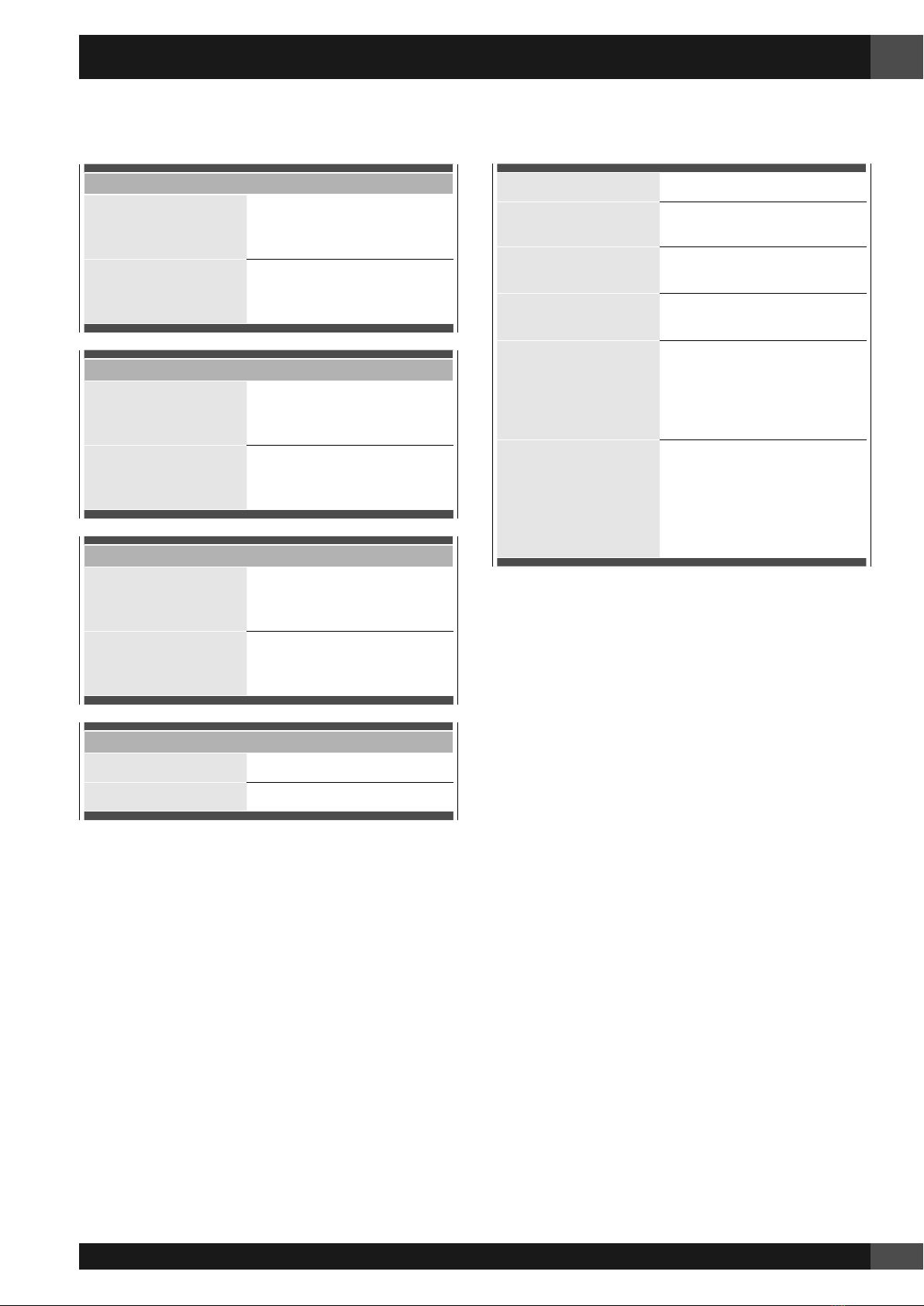

3.2 Electrical and Water connection

NOTE

The Built-in filter cannot make it safe to drink any water

which is not already suitable for human consumption.

WARNING

The appliance should be connected only to a potable

water supply system.

IMPORTANT

Do not use extension cords or adapters.

Once the appliance is fully installed, connected to the

water supply (if applicable) and operational, in the event

that the water supply must be turned off, touch the button

on control panel to disable the ice maker before the

main water is shut off to prevent the appliance from

entering a ‘NO WATER IN’ alarm state.

EW

E W

EW

E W

The appliances are delivered from the factory for operation

at 110V-120V AC - 60Hz (US and Canada).

They are provided with a suitable supply cable and plug to

be connected to an appropriate 15A socket providing an

effective grounding.

A dedicated 15A circuit breaker should also be installed and

should be easily accessible so that it can be easily switched

off before performing any installation or maintenance.

3. Preparing The Installation