1716

ENEN

3.1 Transport to installation site

and unpacking

The appliance is very heavy.

Take maximum care during handling

to avoid injury.

The appliance should always be

transported in an erect position.

Avoid at all costs leaning it on its front

side.

Since this is a large and heavy appliance, before

transporting the appliance, check the access to

the location where it will be installed (door size,

maneuvering space in stairwells, etc.).

The appliance is attached to the base of the packaging

(pallet) through four bolts which can be removed

using a 19 mm (3/4”) wrench.

It isrecommendedto use amanual transporting device

to move the appliance to the installation site, and only

at this point to remove the base of the packaging.

The appliance should always be transported in an

erect position.

If this is not possible, transport the appliance laying

on its rear side.

Once at the installation site, the appliance, which is

equipped with four wheels, can be taken o the pallet

and positioned in the installation area.

Operate as follows:

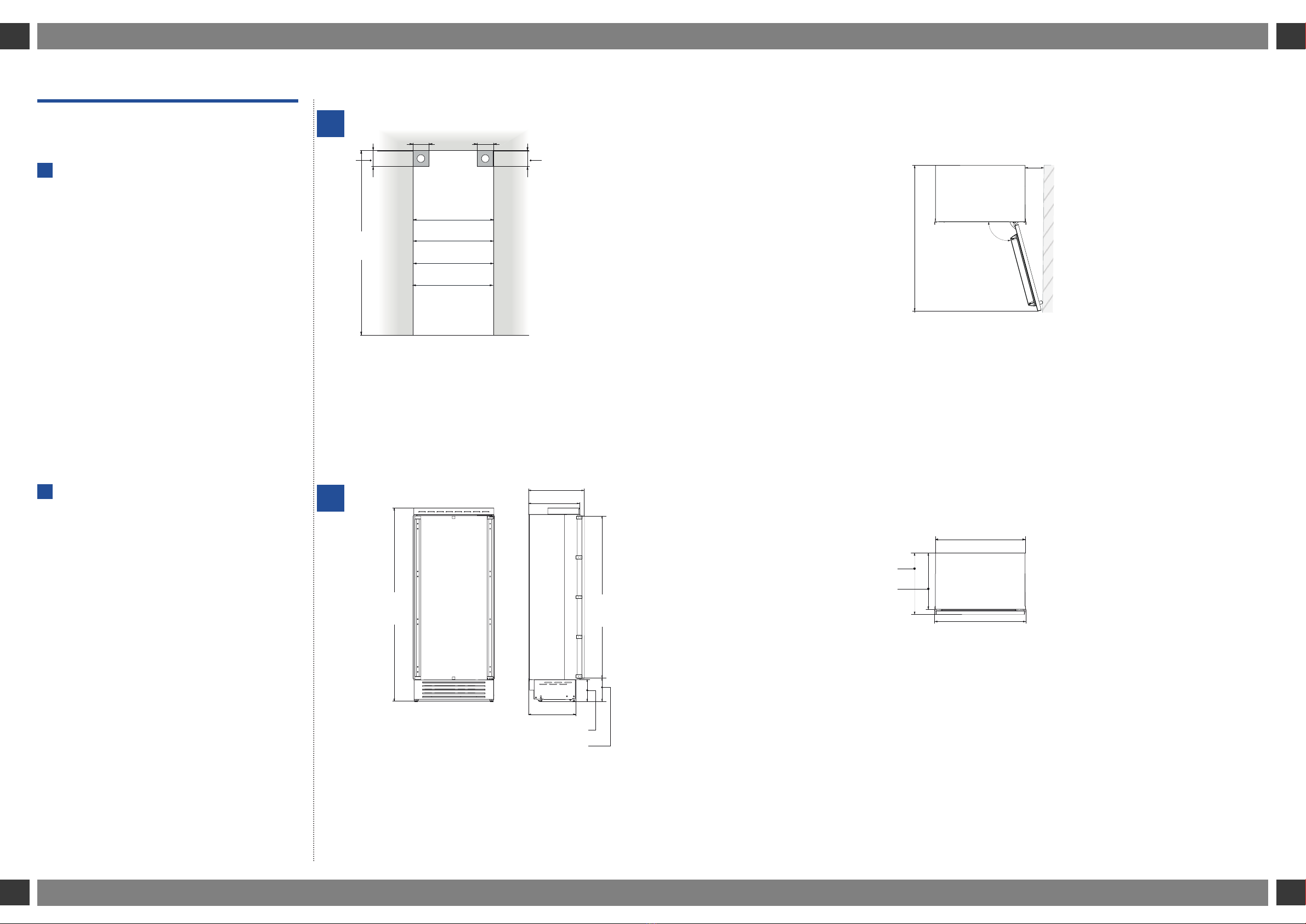

> Take o the four bolts securing [ 1 ] the appliance

to the pallet by means of a 19 mm (3/4”) wrench or

socket.

> Remove the fixing brackets [ 3 ] and [ 4 ] .

> To release the front fixing bracket [ 3 ] , loosen the

rear wheel adjusting bolt [ 2 ] by means of a 13 mm

(1/2”) wrench or socket. Avoid straining this bolt at its

stop points one way or the other so as to not damage

the rear leveling system.

Ensure the front leveling legs are retracted so that

all 4 wheels are able to contact the floor for easiest

maneuvering.

> From the back or side of the unit and by means of a

suitable, heavy duty hand trolley, take o the appliance

and place it on the floor.

Be very careful to avoid any damage to floors.

Delicate floors should be protected with plywood,

hard cardboard or similar material panels.

> At this point, adjust the rear rollers down (clockwise

on the leveling rod [ 2 ]) until they make contact with

the floor and raise the rear of the appliance enough

that it will roll freely

3.2 Electrical and water connection

The supplied water filter cannot make

it safe to drink any water which is not

already suitable for human consumption.

The appliance should be connected only

to a potable water supply system.

Do not use extension cords or adapters.

Once the appliance is fully installed,

connected to the water supply (if

applicable), and operational, in the event

that the water supply must be turned off,

disable the ice maker before the main

water is shut off to prevent the appliance

from entering a ‘NO WATER IN’ alarm

state. Refer to the Use & Care Manual for

how to disable the ice maker.

Electrical or water connections located

directly behind the appliance must be

recessed. Do not put the water shut-off

valve directly behind the appliance.

It should be in an accessible location.

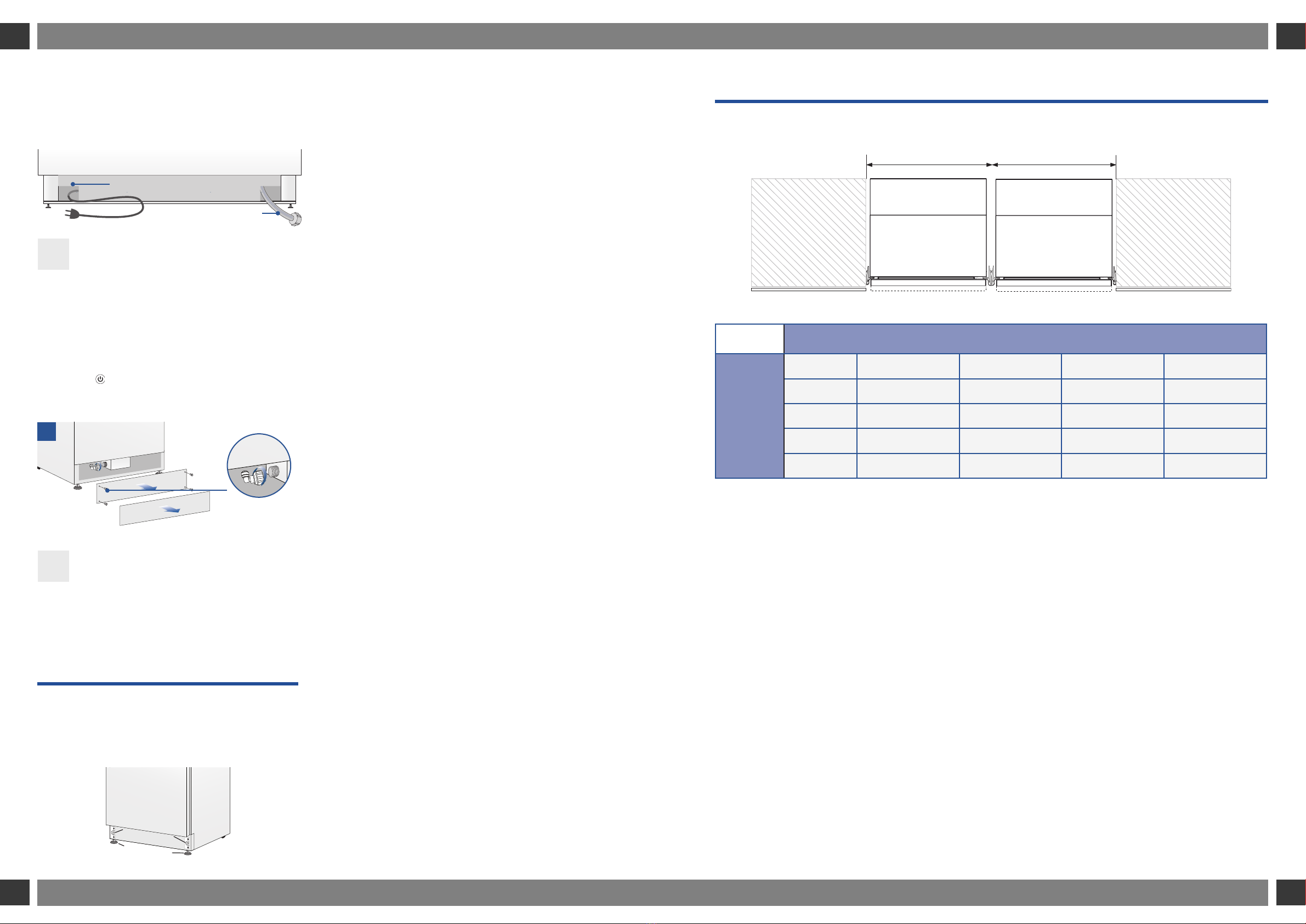

EEEE

E

WWWW

WEW

The appliances are delivered from the factory for

operation at 110V-120V AC - 60Hz (US and Canada).

They are provided with a suitable supply cable and

plug to be connected to an appropriate 15A socket

providing an eective grounding.

A dedicated 15A circuit breaker should also be

installed and should be easily accessible so that it

can be easily switched o before performing any

installation or maintenance.

To connect to the water supply system (for appliances

equipped with ice makers) a 1/4” waterline with

accessible shut-o valve must be supplied.

The appliance is provided with a water adapter

elbow which is suitable for the recommended water

pressure and complies the applicable food and water

regulations.

The water filter cartridge, which is provided with

the appliance, should be installed according to the

accompanying instructions. Please refer to water

filter installation instructions contained in the water

filter kit. The solenoid connection on the appliance

is 3/4” diameter but is metric threaded (NPT).

A standard garden hose threaded connector such as

a braided stainless hose found at typical hardware

stores will strip or damage the solenoid threads. It

is recommended to use only the supplied 1/4” quick

connect elbow adapter for connecting a 1/4” copper

or polyethylene source water line to the appliance.

Do not use extension cords and/or

multiple adapters for the power supply

connection.

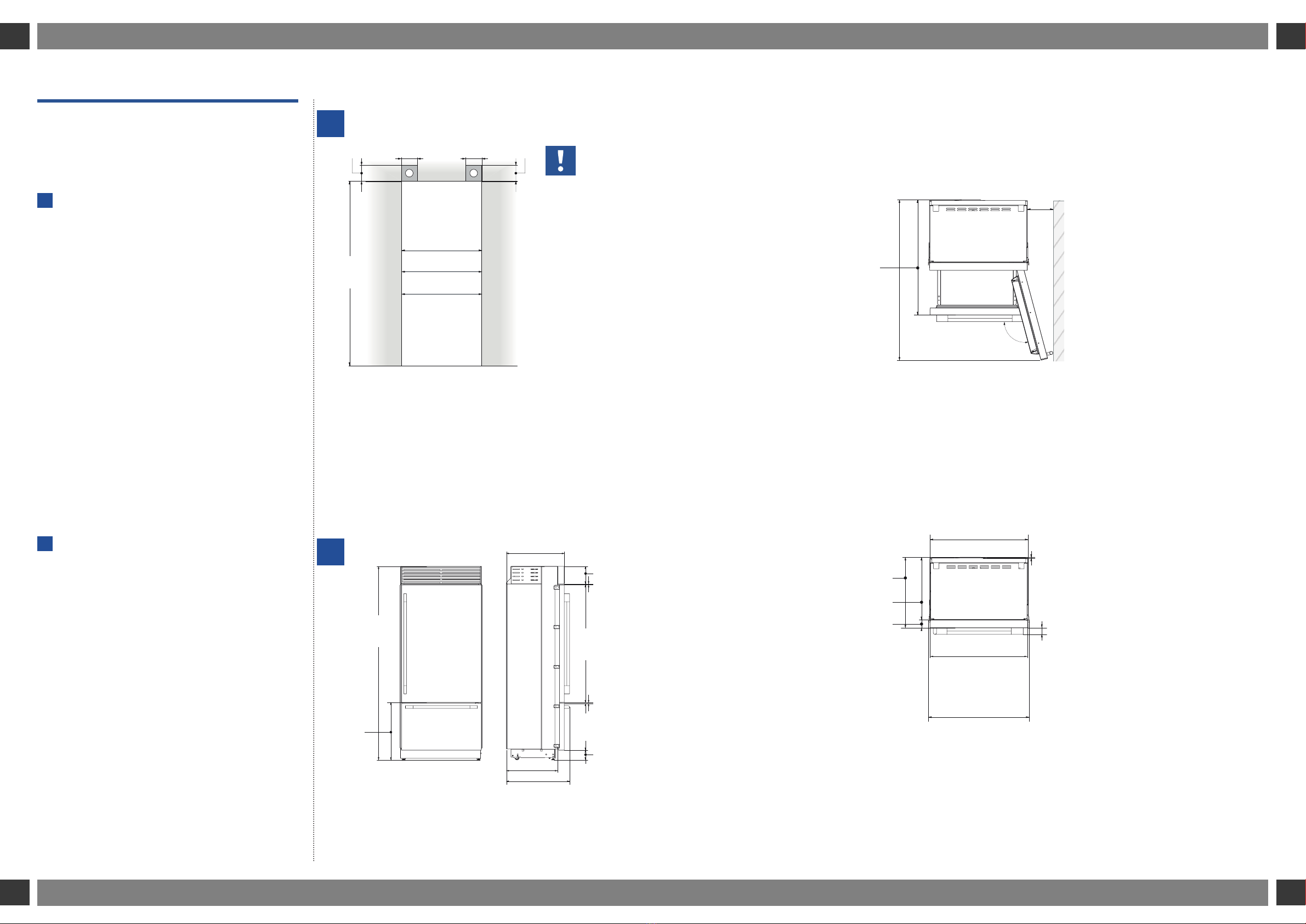

ELECTRICAL AND WATER SUPPLY

BEHIND THE UNIT

BOTTOM COMPRESSORS

UNIT

TOP COMPRESSORS

UNIT

3.3 Energy: Alternatives and Home

Automation

If energy is supplied through an alternative

energy power source (solar, geothermal, etc..)

or if home automation systems are installed

with carrier signals in the power lines, it may

be necessary to install an isolation transformer

(not supplied) to prevent interference with the

appliance’s electronics.

Operate as follows:

> Unwind the electric cable and connect it directly to

the wall socket.

> Make sure the appliance is in the Stand-by condition

and that all lights are o; should it be not so press

the Unit button to switch it o.

> Connect the water cable behind the appliance [ 1 ].

fig.1 Back of appliance

Water connection

Electrical connection

BOTTOM COMPRESSOR UNITS

1

• OVERHEAD VIEW •

3. PREPARING THE INSTALLATION

1

4

1

2

3

E

W

E

W

ELECTICAL & WATER

CONNECTION