8

This appliance is not intended for use by young or infirm persons unless supervised by

a responsible person to ensure that they can use the appliance safely. Young children

should be supervised to ensure that they do not play with the appliance.

¥ To reduce the risk of fire or explosion, never spray flammable liquids in a confined area. It is normal

for the compressor motor and pressure switch to produce sparks during use. If sparks come into

contact with petrol vapours or solvents, they may ignite the vapours and cause a fire or explosion.

¥ Always operate the compressor in a well ventilated area. Do not smoke while spraying. Do not spray

where sparks or flames are present. Keep the compressor as far away from the spray area as possible.

¥ The solvents trichloroethane and methylene chloride can chemically react with the aluminium used

in some paint spray guns and form an explosion. If these solvents are used, ensure that only stainless

steel spray equipment is connected. The compressor is not affected by the use of these solvents.

¥ Never directly inhale the compressed air produced by a compressor and do not use it for charging

breathing tanks.

¥ Do not use welding equipment in close proximity to the compressor. Do not weld anything to the air

tank of the compressor: this could dangerously weaken the tank and will void the warranty.

¥ Do not use the compressor outdoors when it is raining or on a wet surface; either situation could

cause an electric shock.

¥ Always shut off the compressor after use and before servicing.

¥ Check the maximum pressure rating of any tools or accessories that you intend using with the

compressor. The output pressure of the air from the compressor must be regulated so that it never

exceeds the rated pressure of the tool or accessory.

¥ To avoid the risk of burns and injury from moving parts, do not operate the compressor with the

safety shield removed. Allow hot parts to cool before handling or servicing.

¥ Be certain to read all the labels on the containers of paint or other materials to be sprayed. Closely

follow all safety instructions. Use a respirator mask if there is a chance that you might otherwise inhale

the spray material. Carefully check the effectiveness of any respirator mask you intend using.

¥ Always wear safety goggles or glasses when using the air compressor. Never point the nozzle of an

accessory towards any part of your body or towards another person.

¥ Keep the compressor at least 300mm from the nearest wall to ensure adequate ventilation for cooling

purposes.

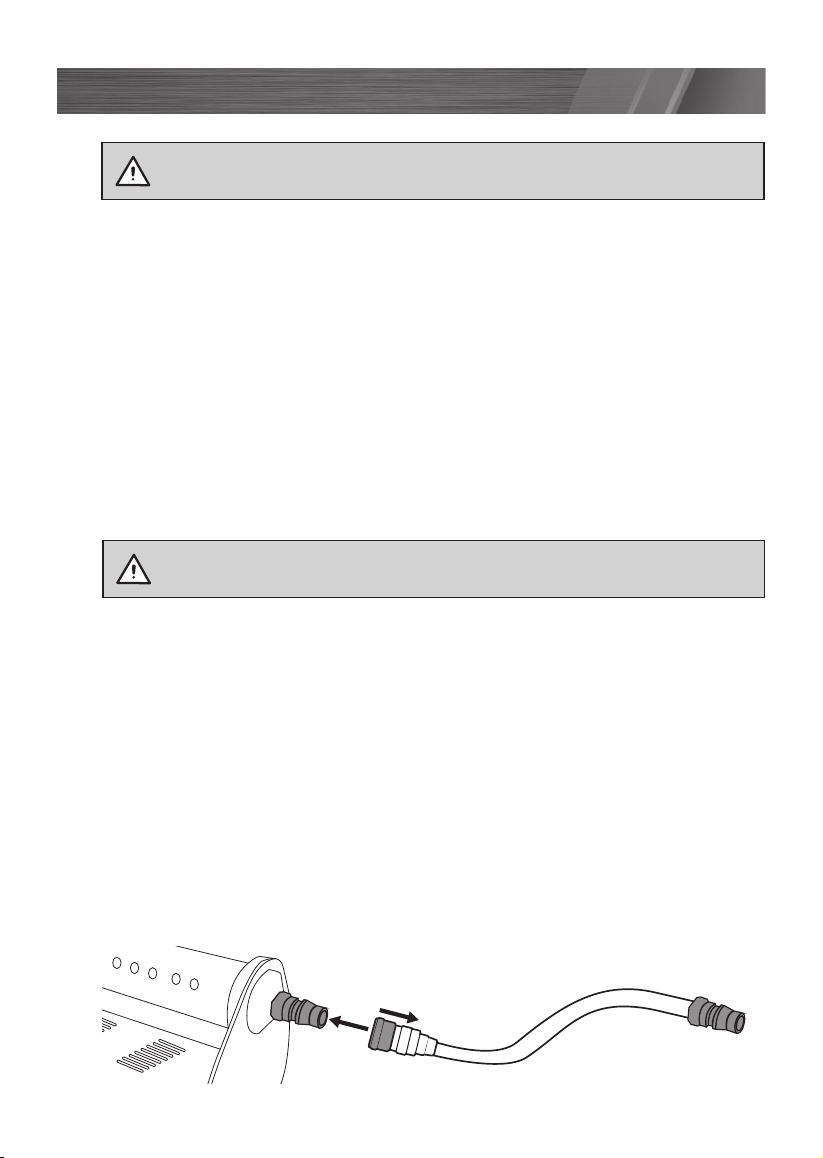

¥ Protect the air hose and cordset from damage. Inspect for weak or worn spots regularly and replace if

necessary.

¥ After long working periods external metal parts could be hot.

¥ Always press the on/off button down to switch off the compressor before switching off the power or

removing the power plug.

¥ After using the compressor, switch off the on/off button, disconnect the power supply.

Wear goggles, wear ear muffs, wear a breathing mask

Never apply the outlet air of this compressor directly on to any part of a persons body. Do not attempt to

block the air outlet with your finger or any part of your body.

The tool must be used only for its prescribed purpose. Any use other than those mentioned in this Manual

will be considered a case of misuse. The user and not the manufacturer shall be liable for any damage or

AIR COMPRESSOR SAFETY WARNINGS

WARNING! Before connecting a tool to a power source (mains switch, power

point, receptacle, outlet, etc.) be sure that the voltage supply is the same as that

specified on the nameplate of the tool. A power source with a voltage greater

than that specified for the tool can result in serious injury to the user, as well as

damage to the tool. If in doubt, do not plug in the tool. Using a power source

with a voltage less than the nameplate rating is harmful to the motor.