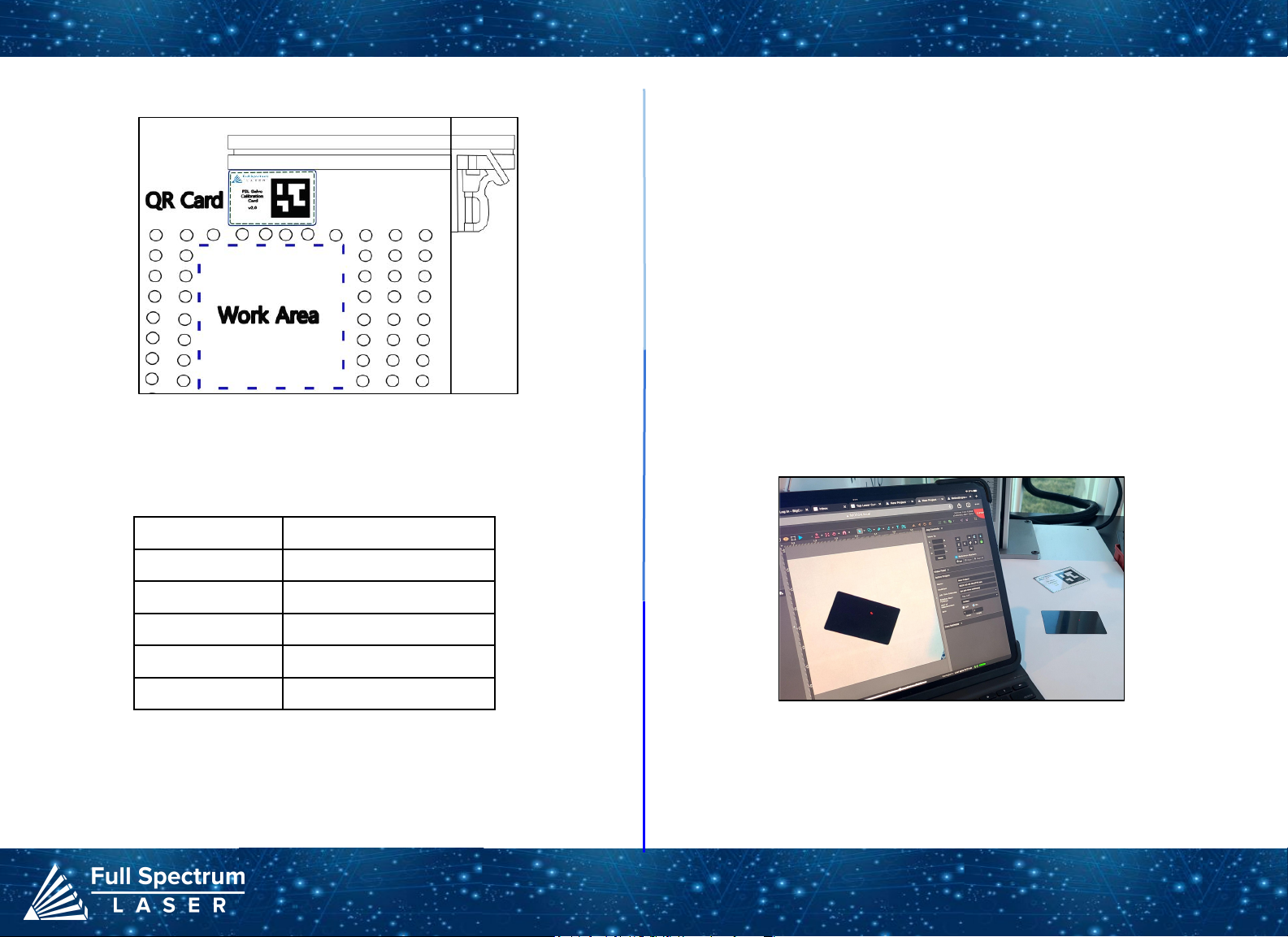

Connect to Software

Create or Import Design

Place Material

Focus Lens

Align Material to Engraving Areas

Adjust Object Properties

Run Job

Project Procedure: Troubleshooting:

For more information on your machine refer to your user manual. For

information on RE3, refer to the RE3 Guide found in our website.

9

Q: What should I do if my laser isn't marking?

A: Check if the laser is properly focused. If the machine is not at the right height, it won't

engrave. Refocus the laser head after changing to a new material. Still having difficulties, make

sure that your material is compatible with your laser engraver.

Q: Why are my marks turning out incorrect?

A: Experiment with different settings to find the ones that work best for your requirements. Here

are some initial guidelines to get started:

● To get darker/lighter engravings, adjust the power or speed.

● To get deeper engravings, decrease the speed or increase passes.

● For clearer engravings, use a picture with a high resolution.

Q: What should I do if my engravings are too shallow?

A: You may need to increase the power and/or decrease the speed. Multiple passes can also

add more depth. You can also use a smaller lens to engrave in more detail. For precise

engravings, ensure that the laser is fully focused by performing a laser focus test every time

you switch to a new material.

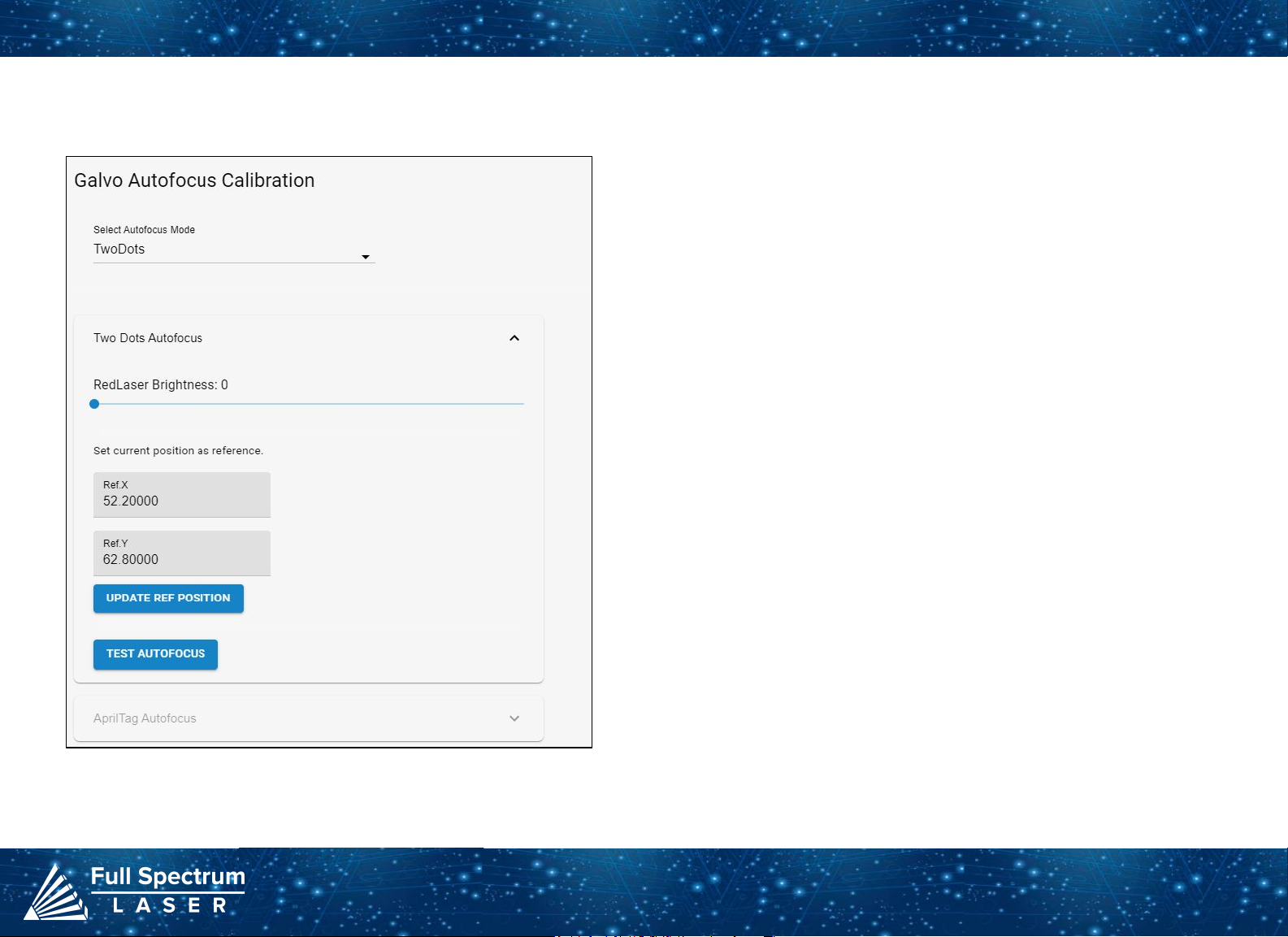

Q: How can I solve issues with focusing my laser?

A: If using auto-focusing with the QR tag, ensure that the QR tag is visible in the camera during

the entire process. If the tag goes off-screen, the machine won't focus. If it doesn't work, try

manual focusing.

Q: What should I do if my engravings look wobbly and uneven?

A: If you've recently calibrated your camera, check that you did it on a flat, smooth, and level

surface. Otherwise, recalibrate on a different surface. Another reason could be that your

material is not flat while engraving, it can come out uneven. Flatten and/or weigh down your

material before engraving to avoid this issue.

If your having an issue not listed here, visit our Help Center. We provides comprehensive

videos, and useful resources for troubleshooting to helping you get the most out of your

investment in our products.