www.furuno.com

ll brand and product names are trademarks, registered trademarks or service marks of their respective holders.

Installation Manual

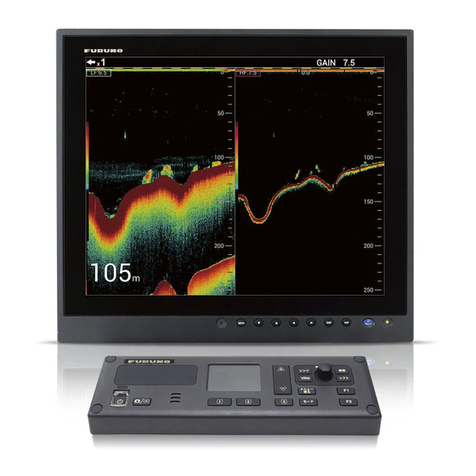

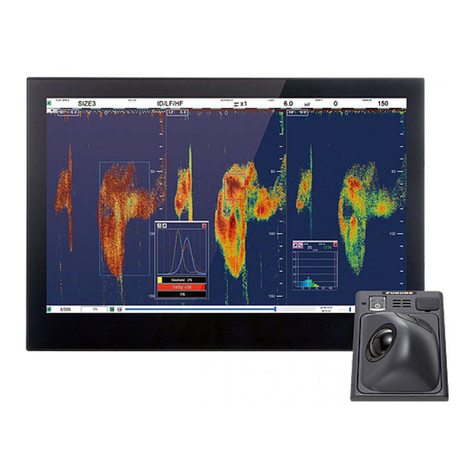

FISH SPECIES AND BIOMASS SOUNDER

Model FSS-3BB

(Product Name: FISH FINDER)

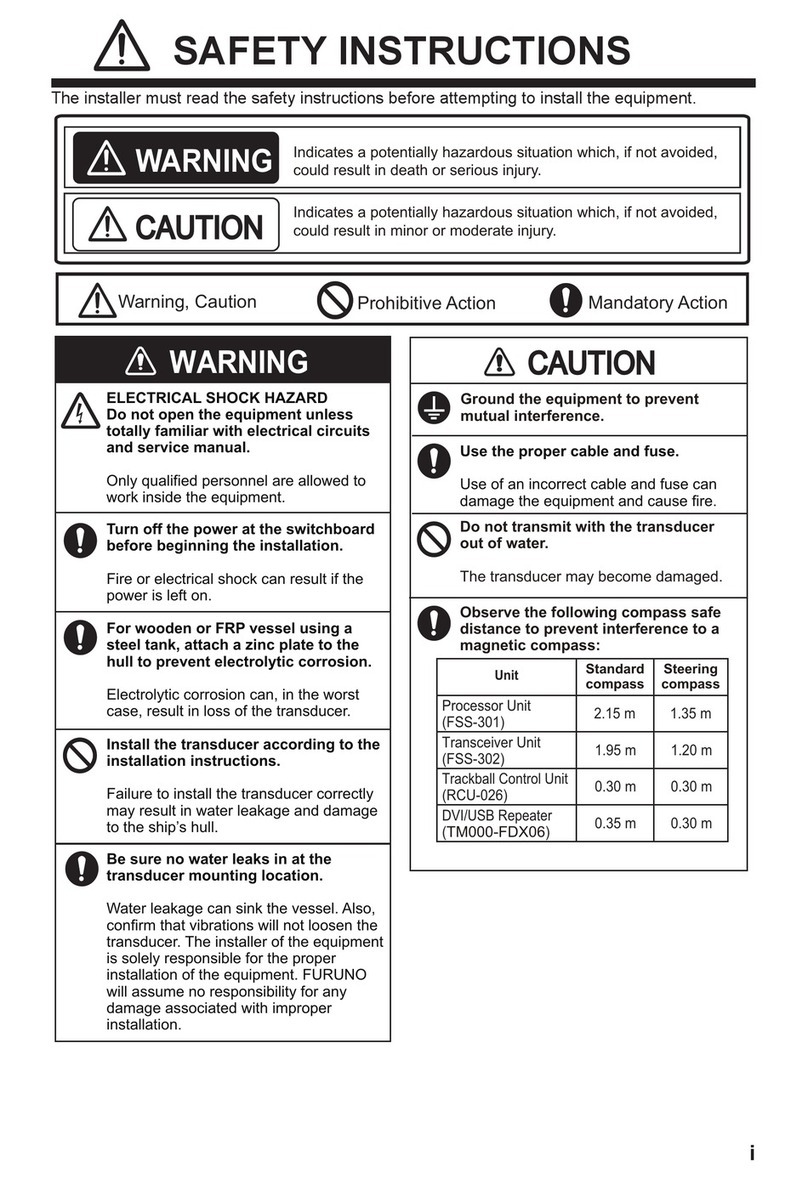

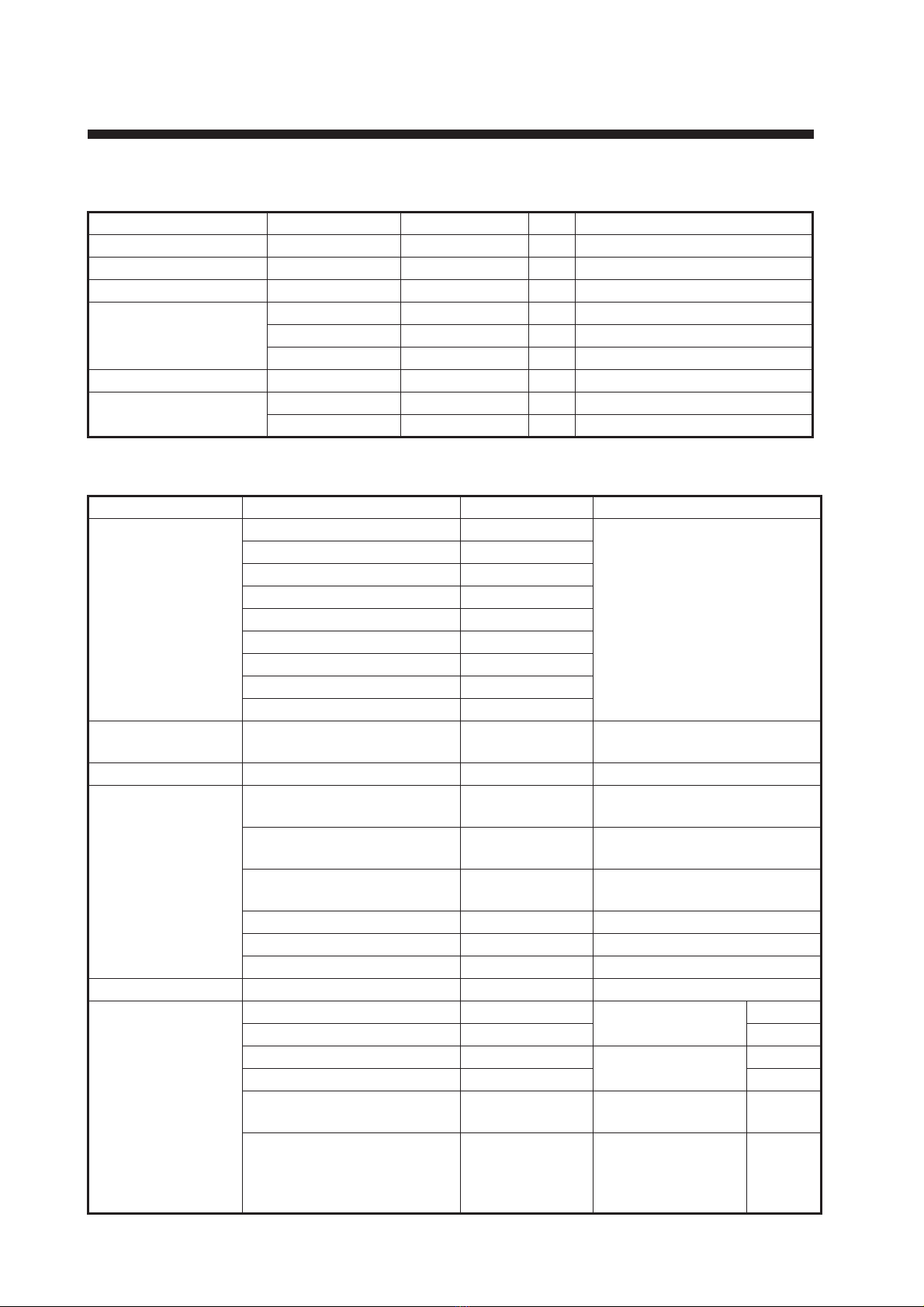

SAFETY INSTRUCTIONS ................................................................................................ i

SYSTEM CONFIGURATION .......................................................................................... iii

EQUIPMENT LISTS........................................................................................................ iv

1. MOUNTING..............................................................................................................1-1

1.1 Processor Unit ...................................................................................................................1-1

1.2 Transceiver Unit.................................................................................................................1-3

1.3 Trackball Control Unit ........................................................................................................1-4

1.4 Transducer.........................................................................................................................1-7

1.5 DVI/USB Repeater (Option)...............................................................................................1-9

1.6 Monitor Unit (Local Supply)..............................................................................................1-11

2. WIRING....................................................................................................................2-1

2.1 Processor Unit ...................................................................................................................2-2

2.2 Transceiver Unit.................................................................................................................2-6

2.3 Trackball Control Unit ......................................................................................................2-10

2.4 DVI/USB Repeater (Option).............................................................................................2-12

2.5 Input/Output Sentences (NMEA0183) .............................................................................2-14

3. INITIAL SETTINGS..................................................................................................3-1

3.1 Initial Setting Menu ............................................................................................................3-1

3.2 How to Set the Service Menu ............................................................................................3-5

3.3 Communication Port Setting ............................................................................................3-11

3.4 [Calibration] Menu............................................................................................................3-13

3.5 [Stabilization] Menu..........................................................................................................3-15

3.6 How to Take a Still Image of the RX Monitor...................................................................3-17

3.7 Model Data for the IDENTI-FISH™Graph .......................................................................3-17

3.8 Reset to Default Setting...................................................................................................3-18

APPENDIX 1 JIS CABLE GUIDE .............................................................................AP-1

PACKING LISTS ......................................................................................................... A-1

OUTLINE DRAWINGS ................................................................................................ D-1

INTERCONNECTION DIAGRAMS.............................................................................. S-1