www.furuno.com

ll brand and product names are trademarks, registered trademarks or service marks of their respective holders.

Installation Manual

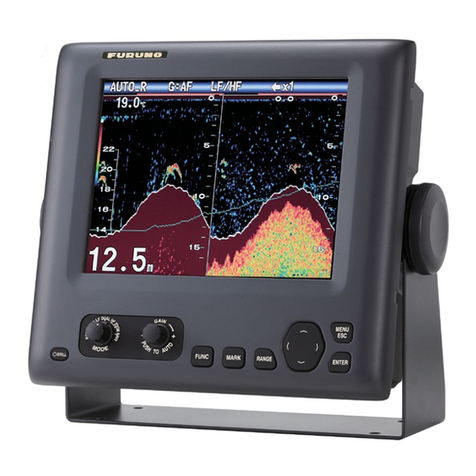

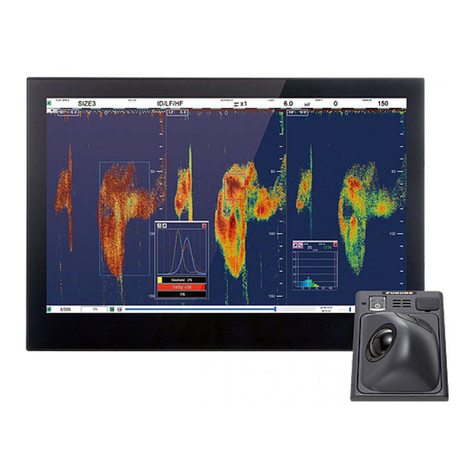

FISH FINDER/ HI-RES FISH FINDER/

FISH SIZE INDICATOR

Model FCV-1900/B/G

(Product Name: FISH FINDER)

SAFETY INSTRUCTIONS ................................................................................................ i

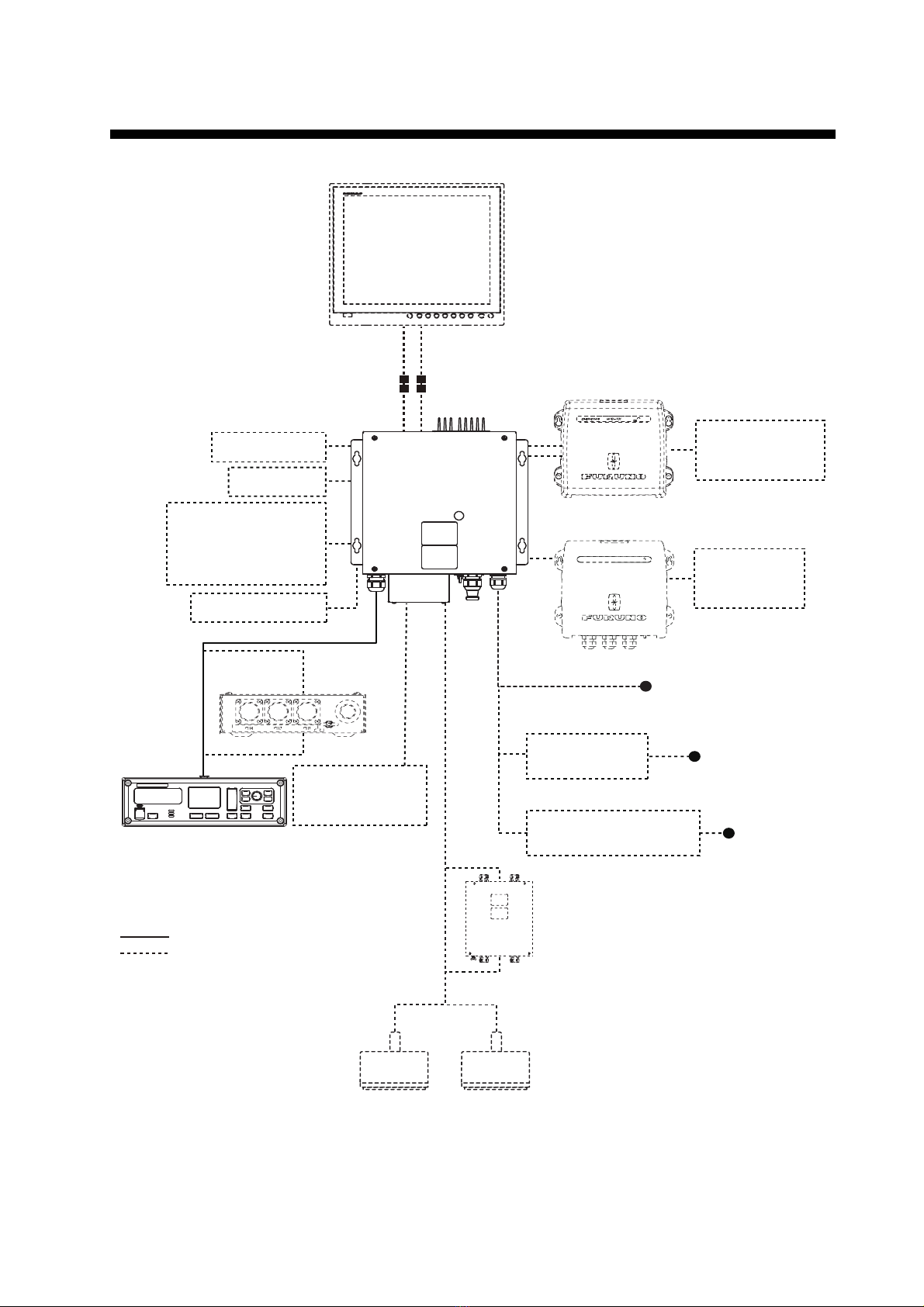

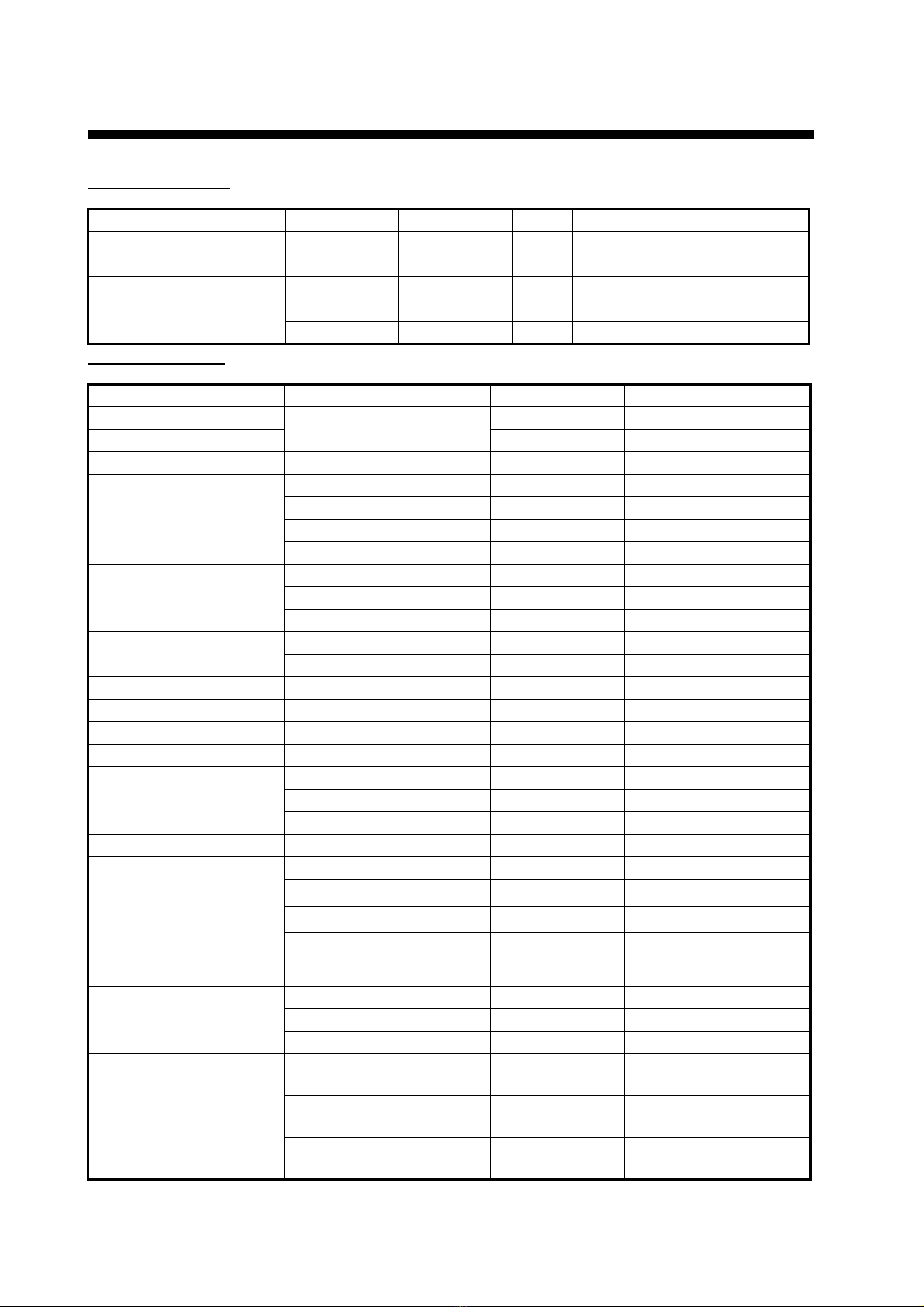

SYSTEM CONFIGURATION ........................................................................................... ii

EQUIPMENT LISTS........................................................................................................ iii

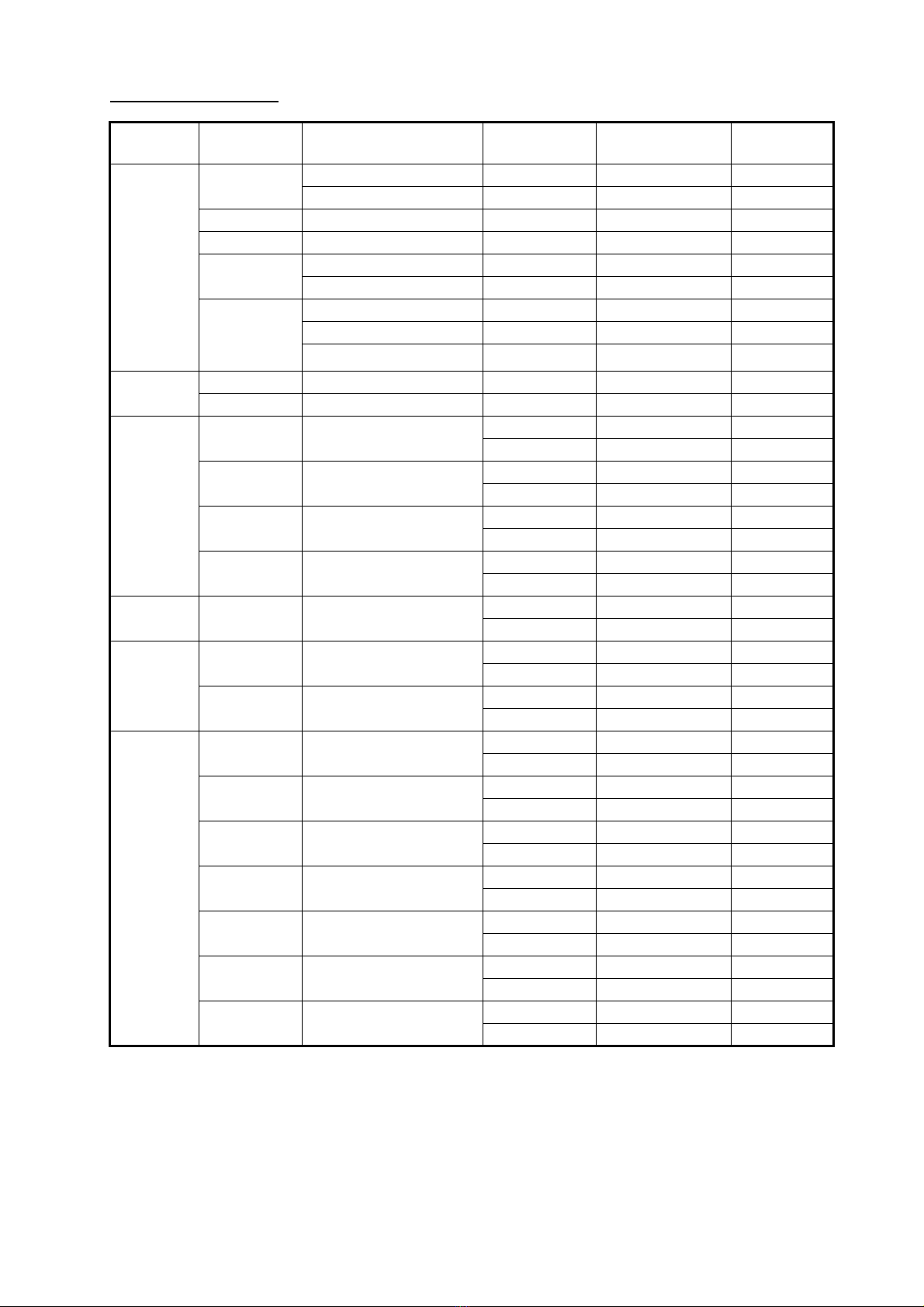

1. MOUNTING................................................................................................................. 1

1.1 Processor Unit ......................................................................................................................1

1.2 Control Unit ...........................................................................................................................2

1.3 Transducer............................................................................................................................3

1.4 External Monitor....................................................................................................................3

1.5 Interface Unit.........................................................................................................................3

1.6 Ethernet HUB........................................................................................................................4

1.7 Booster Box ..........................................................................................................................5

1.8 Temperature Sensor .............................................................................................................5

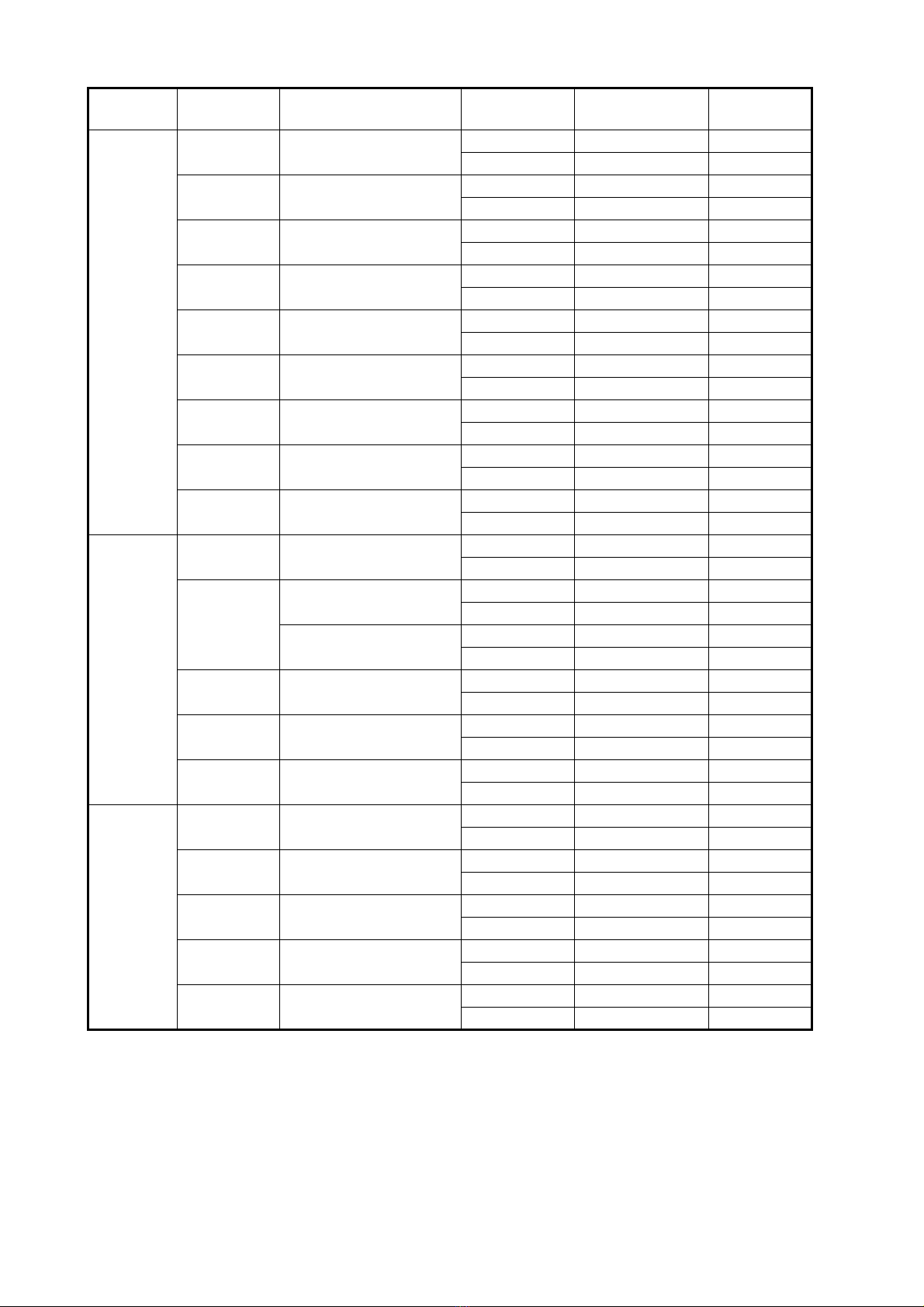

2. WIRING....................................................................................................................... 6

2.1 Interconnection .....................................................................................................................6

2.2 Processor Unit ......................................................................................................................7

2.3 Interface Unit.......................................................................................................................12

2.4 Net Sonde ...........................................................................................................................15

2.5 Ethernet HUB......................................................................................................................16

2.6 Booster Box ........................................................................................................................16

2.7 Input/Output Sentences ......................................................................................................17

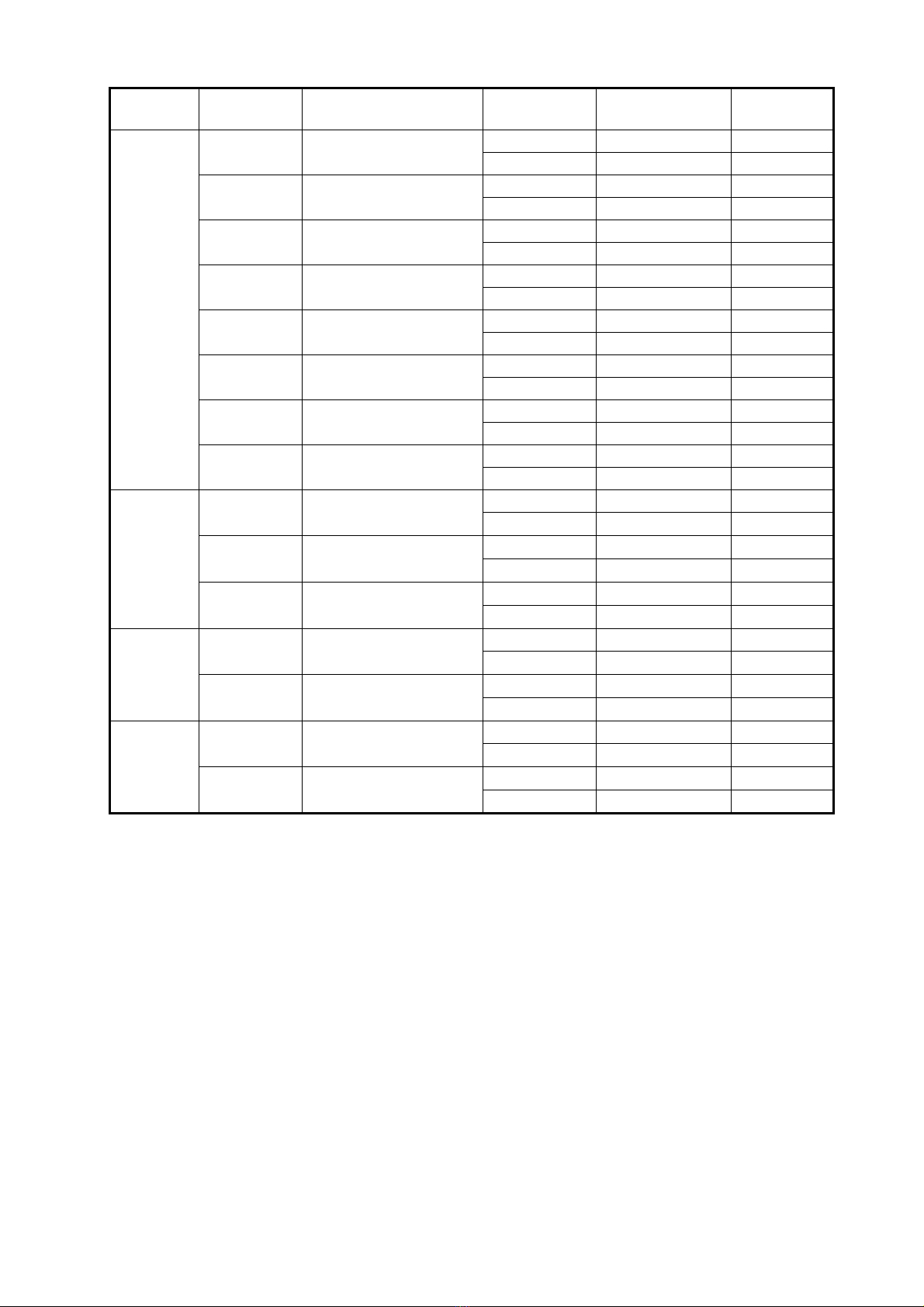

3. INITIAL SETTINGS................................................................................................... 18

3.1 Installation Menu.................................................................................................................18

3.2 Monitor Setting....................................................................................................................19

3.3 Transducer Setting..............................................................................................................20

3.4 NMEA Port Setting..............................................................................................................23

3.5 Communication Port Monitor ..............................................................................................24

3.6 Calibration Setting...............................................................................................................25

3.7 Stabilization Setting ............................................................................................................26

3.8 Telesounder Setting............................................................................................................27

3.9 Reset to Default Setting......................................................................................................27

3.10 Upgrading to FCV-1900B/1900G........................................................................................27

APPENDIX 1 JIS CABLE GUIDE .............................................................................AP-1

APPENDIX 2 INSTALLATION OF TEMPERATURE SENSORS .............................AP-2

PACKING LISTS ......................................................................................................... A-1

OUTLINE DRAWINGS ................................................................................................ D-1

INTERCONNECTION DIAGRAM ................................................................................ S-1