ii

SAFETY INSTRUCTION

WARNING

Do not open the cover of

the equipment.

This equipment uses high

voltage electricity which can

shock or burn.

Only qualified personnel

should work inside the

equipment.

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury can

result.

Immediately turn off the power at the

ship's mains switchboard if water or

foreign object falls into the equipment

or the equipment is emitting smoke or

fire.

Continued use of the equipment can cause

fire, electrical shock or serious injury.

Do not operate the unit with wet hands.

Electrical shock can result.

Use the correct fuse.

Use of the wrong fuse can cause fire or

damage the equipment.

WARNING

ELECTRICAL SHOCK HAZARD

Only qualified personnel

should work inside the

equipment.

This equipment uses high

voltage electricity which can

shock or burn.

Turn off the power at the ship's mains

switchboard before beginning the

installation. Post a warning sign near

the switchboard to ensure that the

power will not be applied while the

equipment is being installed.

Serious injury can result if the power is

not turned off, or is applied while the

equipment is being installed.

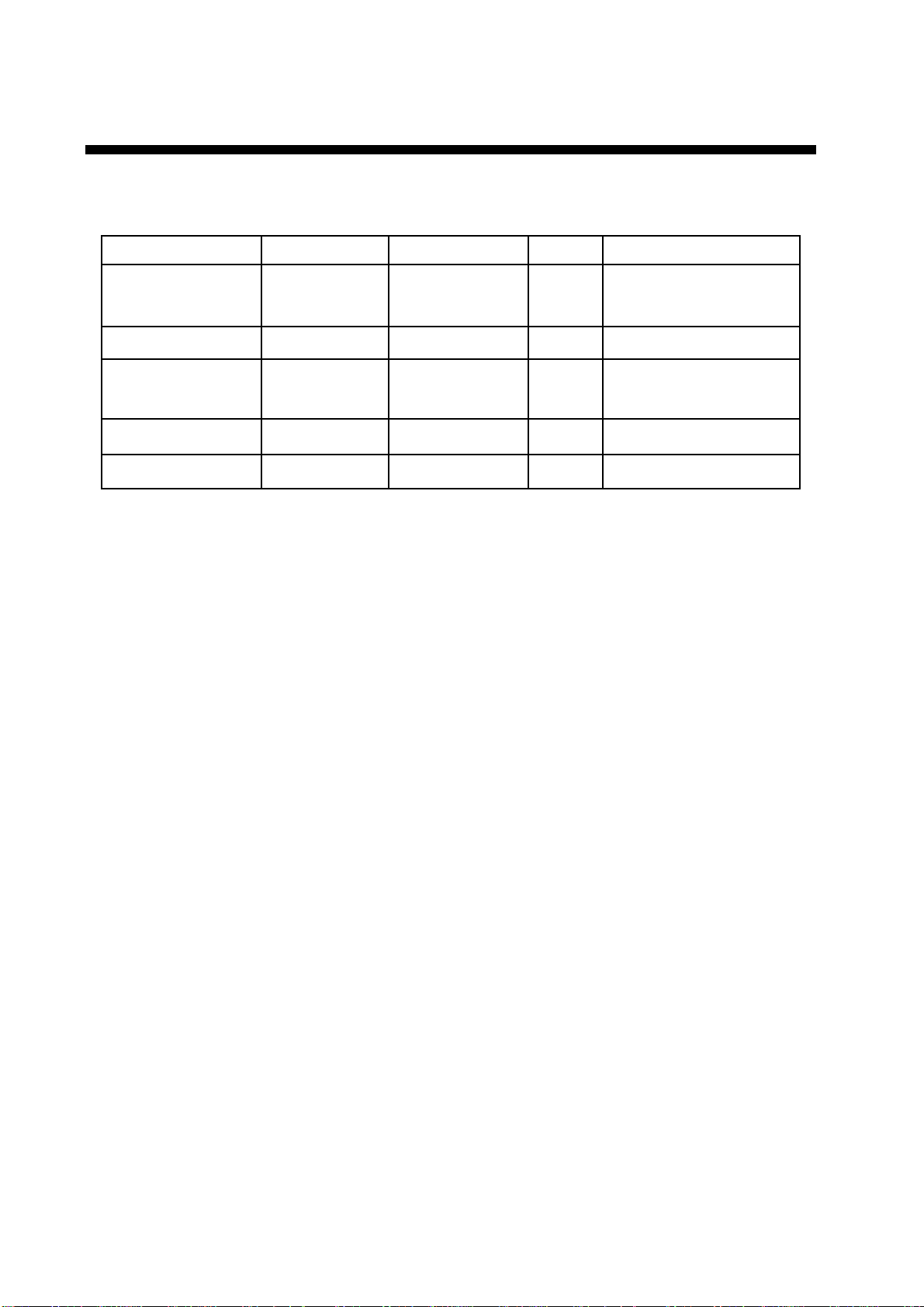

CAUTION

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

CAUTION

PP-505 1.1 m 0.8 m

standard

compass

steering

compass

Safety Information for Operator Safety Information for Installer

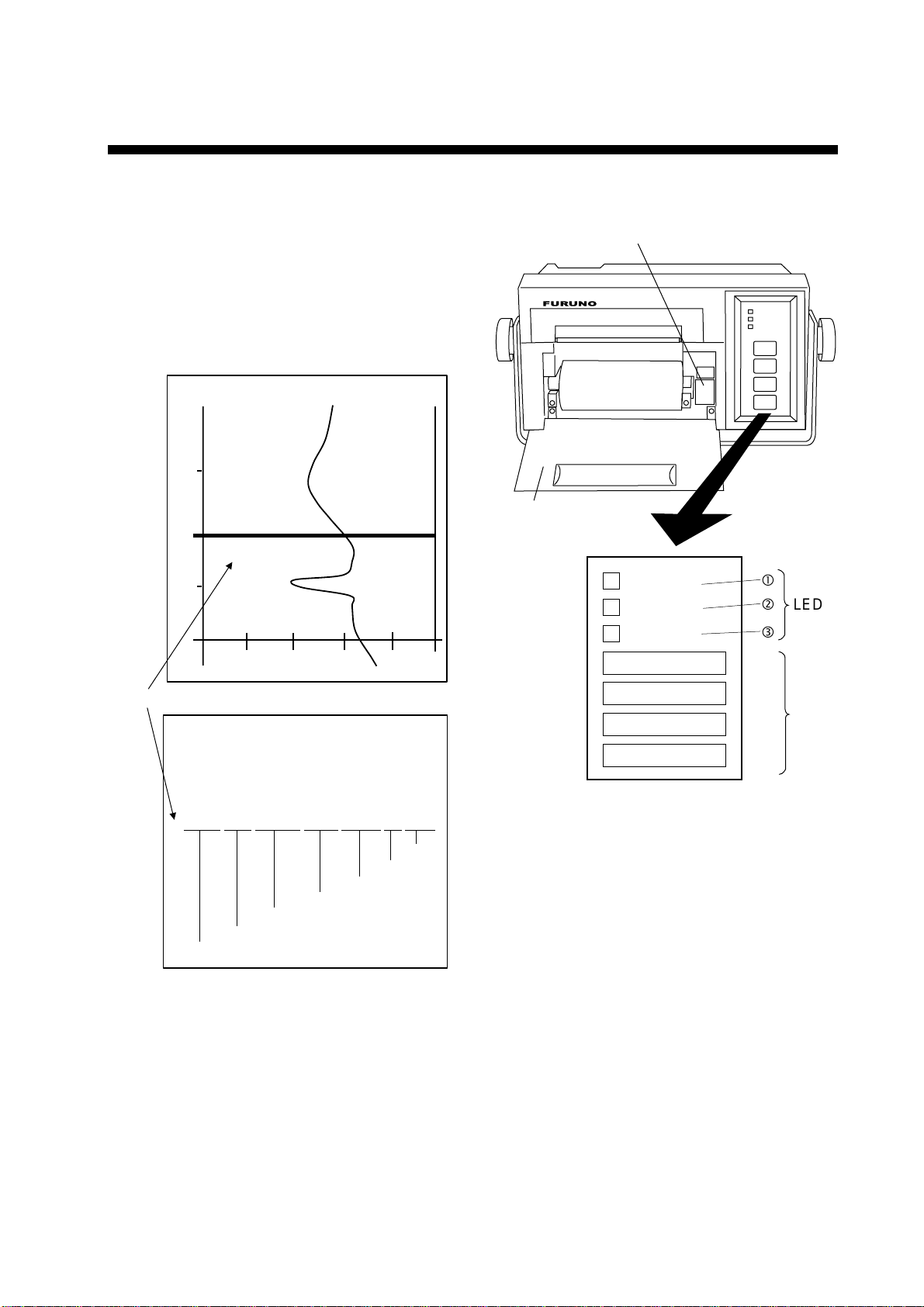

A warning label is attached

to the printer. Do not remove

the label. If the label is missing

or damaged, contact your dealer

about replacement.

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

Name: Warning Label (1)

Type: 86-003-1011

Code No.: 100-236-231

WARNING LABEL

WARNING

Indicates a condition that can cause death or serious

injury if not avoided.

CAUTION

Indicates a condition that can cause minor or moderate

injury if not avoided.

Warning, Caution Mandatory Action

Prohibitive Action

Read these safety instructions before you operate the equipment.