CONTENTS

SYSTEM CONFIGURATION................................................................................1

1. FUNCTION OF EACH UNIT

1.1 Display Unit (MU-100C)..................................................................................3

1.2 Control Unit (CH-252)......................................................................................4

1.3 Transceiver Unit (CH-273) ...............................................................................5

1.3.1 CPU Board (06P0258)............................................................................5

1.3.2 TRX Board (06P0241) ...........................................................................6

1.3.3 PWR Board (06P0242)...........................................................................7

1.3.4 PRA Board (06P0259)............................................................................8

2. FUNCTIONAL DESCRIPTION

2.1 Transmission.....................................................................................................9

2.2 Reception..........................................................................................................9

2.3 Raising/Lowering Transducer.........................................................................12

2.4 Tilting Transducer...........................................................................................13

2.5 Training Transducer........................................................................................15

2.6 Braking Tilt/Train Motor ................................................................................17

3. CHECK AND ADJUSTMENT

3.1 Test Points.......................................................................................................18

3.2 LED Indication................................................................................................21

3.3 Adjustment......................................................................................................22

4. PARTS LOCATION

4.1 Display Unit....................................................................................................24

4.2 Control Unit....................................................................................................26

4.3 Transceiver Unit..............................................................................................26

5. MAINTENANCE

5.1 Replacement of Grease Cotton .......................................................................32

5.2 Soundome (D) Replacement...........................................................................32

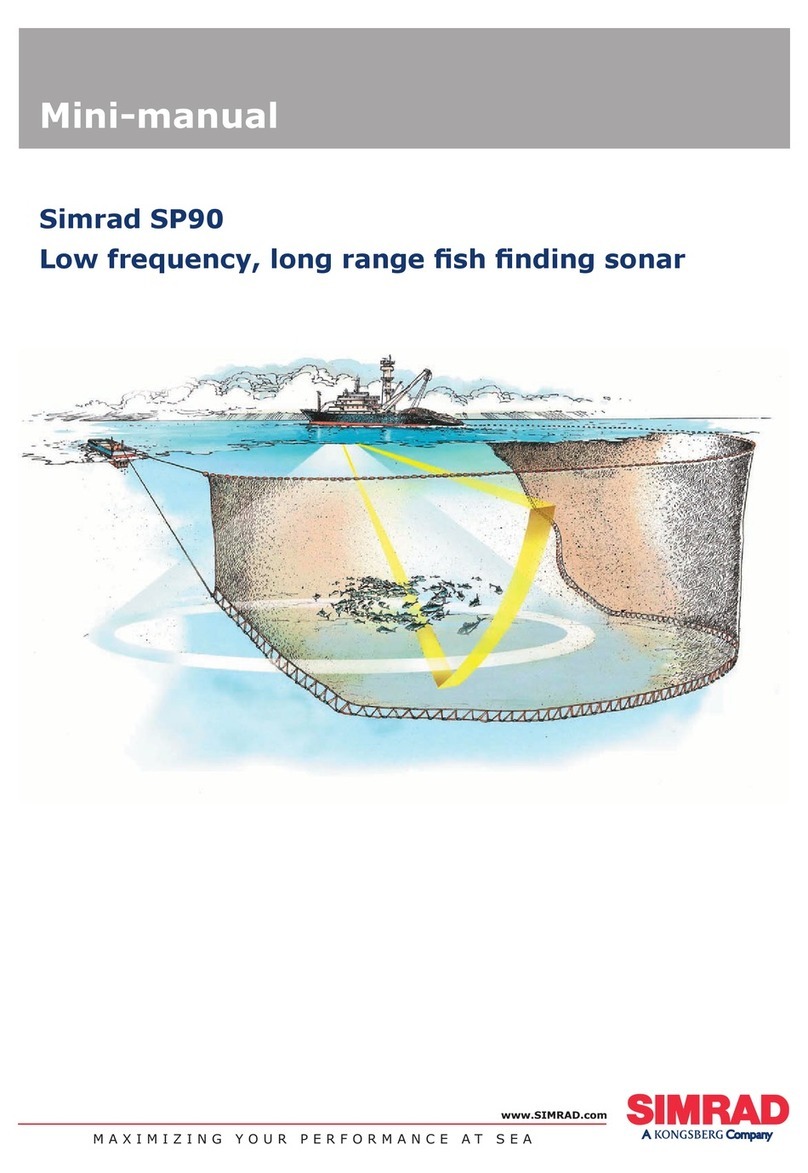

5.3 Transducer Replacement.................................................................................34

5.4 Tilt Gear Box Replacement.............................................................................35

5.5 Slip Ring Replacement....................................................................................36

5.6 Carbon Brush Replacement ............................................................................37

5.7 Tilt Code Disk Alignment...............................................................................38

6. TROUBLESHOOTING

6.1 Flow Chart ......................................................................................................40

Appendix A CH-250 vs CH-270..............................................................................46

Mechanical Parts List ................................................................................... 48

Exploded view .............................................................................................D-1

Schematic Diagram .......................................................................................S-1