Furuno FSV-84 User manual

Other Furuno Sonar manuals

Furuno

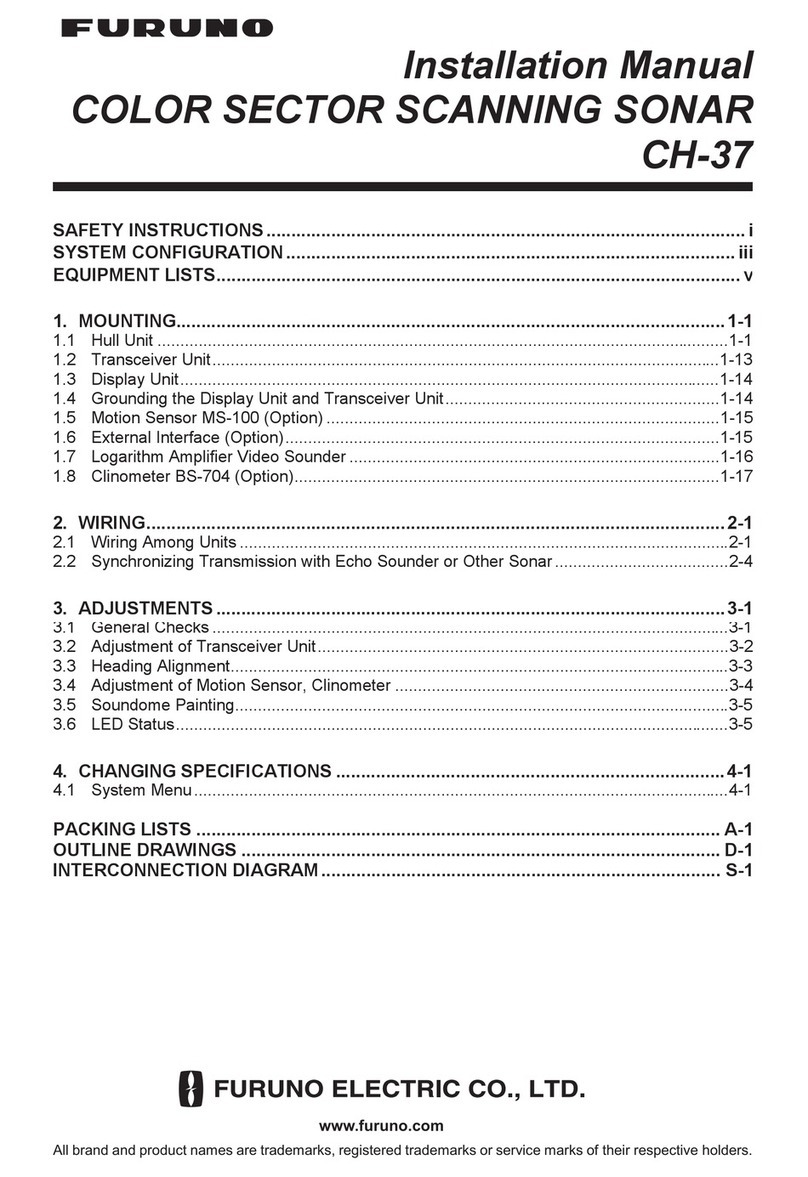

Furuno CH-37 User manual

Furuno

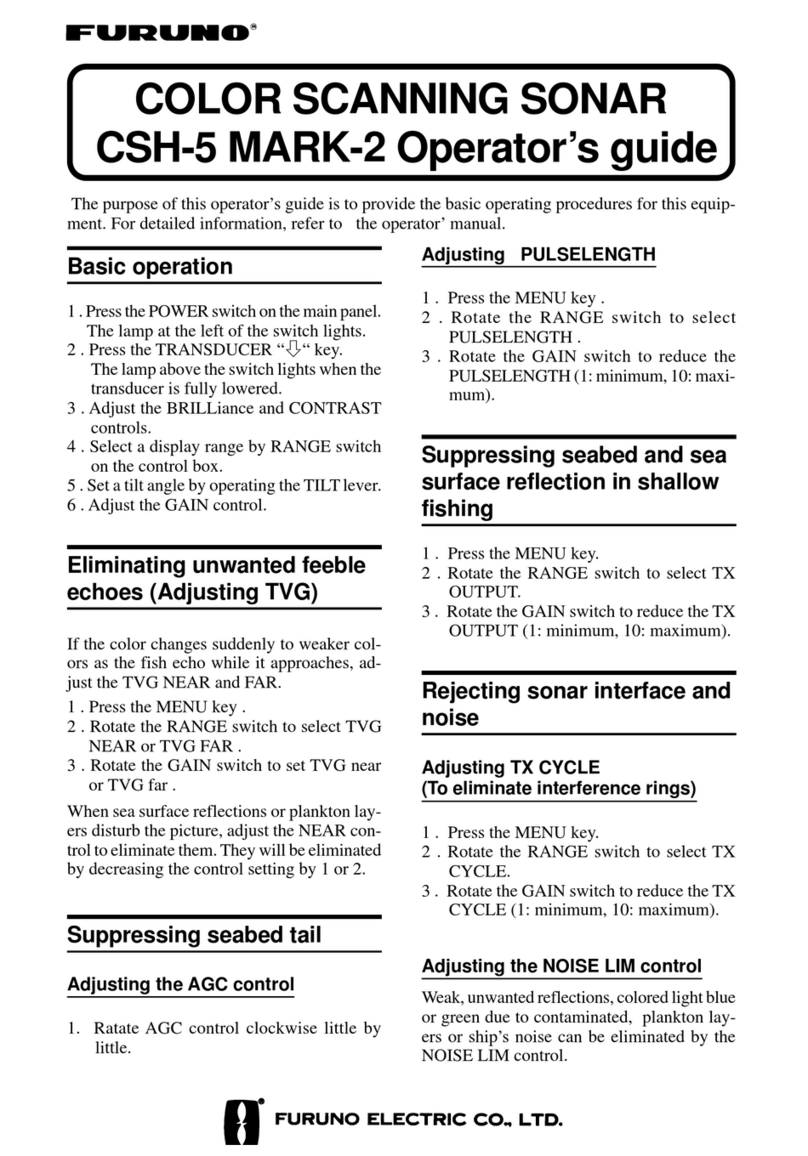

Furuno CSH-5 MARK-2 Manual

Furuno

Furuno DS-60 User manual

Furuno

Furuno CH-500 User manual

Furuno

Furuno CH-300 User manual

Furuno

Furuno CSH-5L User manual

Furuno

Furuno CH-250 User manual

Furuno

Furuno CH-270 User manual

Furuno

Furuno CH-18 User manual

Furuno

Furuno CSH-5L User manual

Furuno

Furuno FSV-85-MARK-2 User manual

Furuno

Furuno FSV-35S User manual

Furuno

Furuno 3D Sonar Visualizer F3D-S User manual

Furuno

Furuno FSV85MK2 User manual

Furuno

Furuno CH-32 User manual

Furuno

Furuno CSH-8LMARK-2 User manual

Furuno

Furuno FSV-30 User manual

Furuno

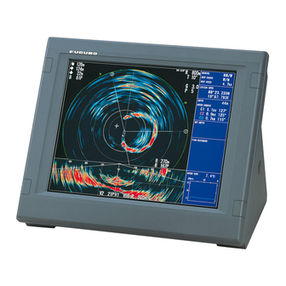

Furuno CSH-7 User manual

Furuno

Furuno COLOR SCANNING CSH-55 User manual

Furuno

Furuno CH-37BB User manual

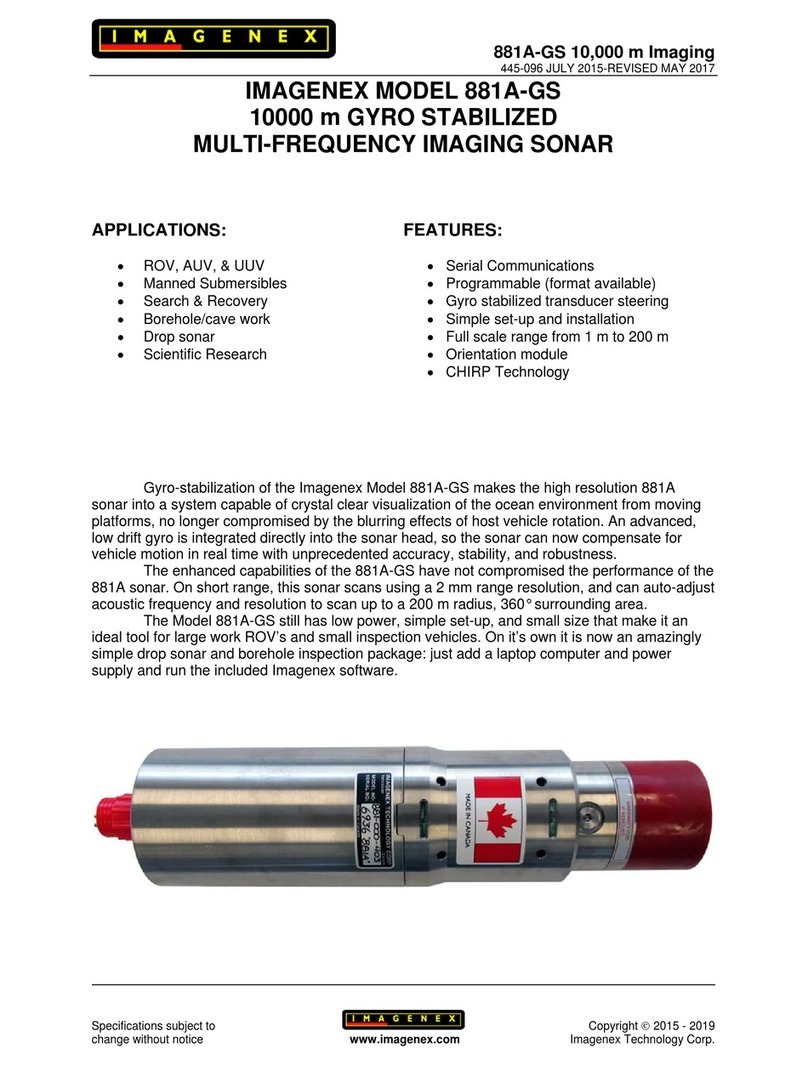

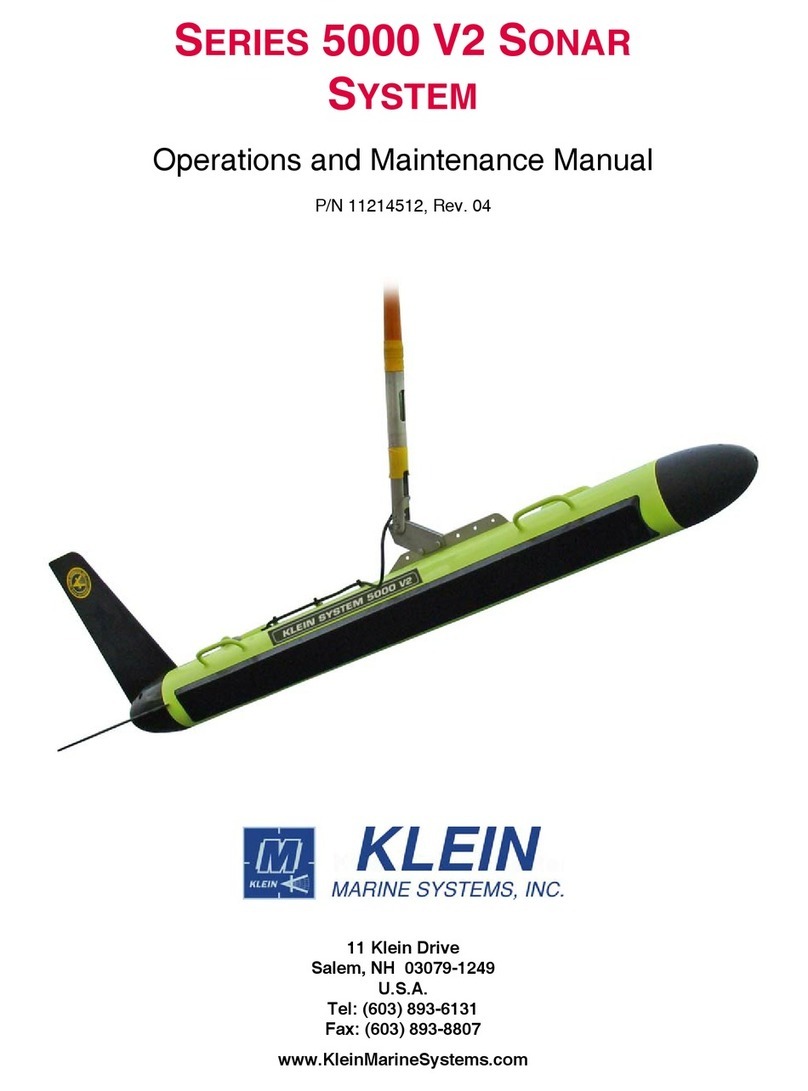

Popular Sonar manuals by other brands

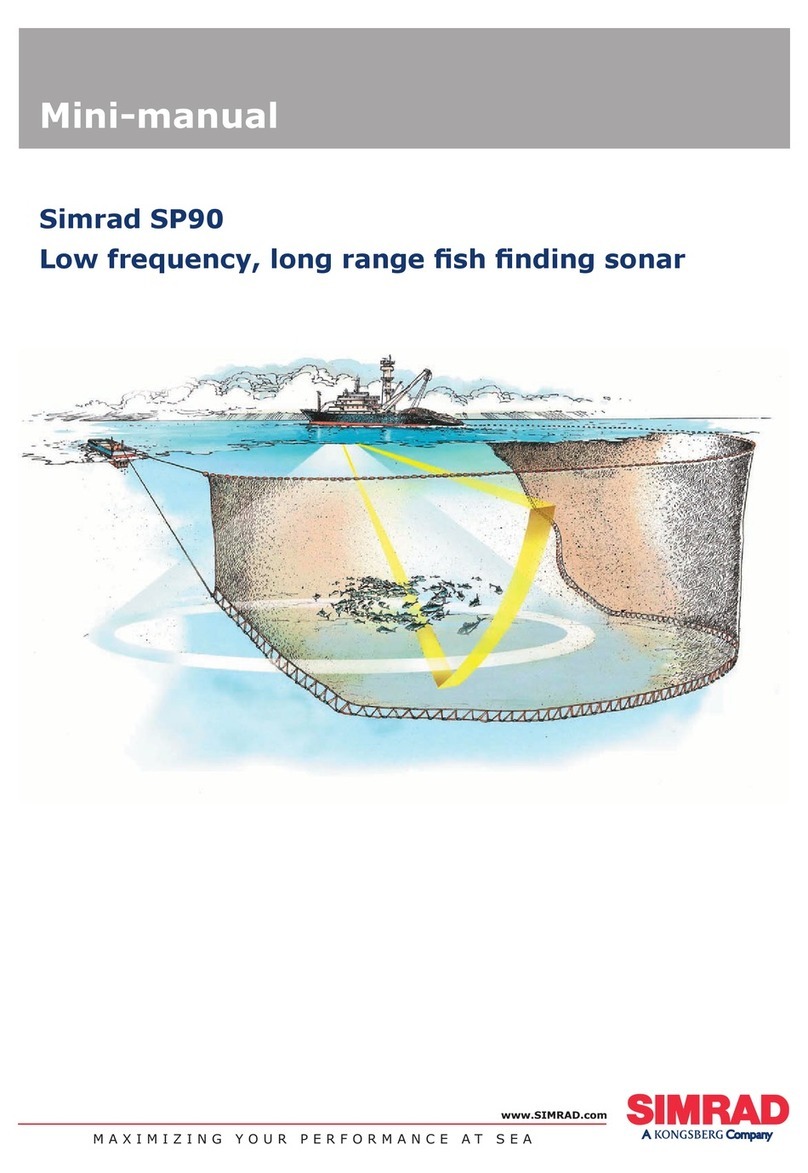

Kongsberg

Kongsberg Simrad SP90 Series manual

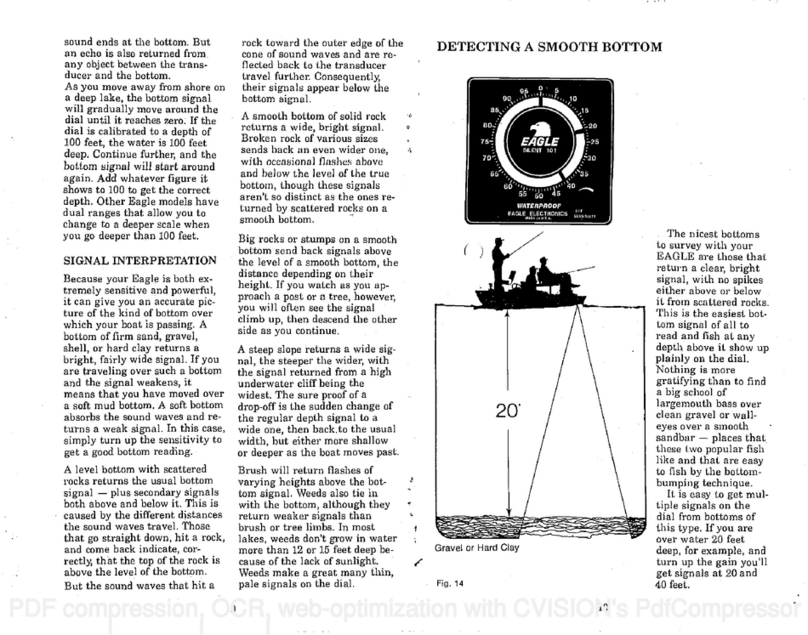

Eagle

Eagle TriFinder 2 Installation and operation instructions

Lowrance

Lowrance X-70A Installation and operation instructions

Lowrance

Lowrance LMS-150 GPS Installation and operation instructions

Simrad

Simrad EQ 55 Operator's manual

Lowrance

Lowrance Traditional Installation