LCF Tension and Compression Sensor Family Manual 10

Sensor Solution Source

Load · Torque · Pressure · Multi-Axis · Calibration · Instruments · Software

www.futek.com

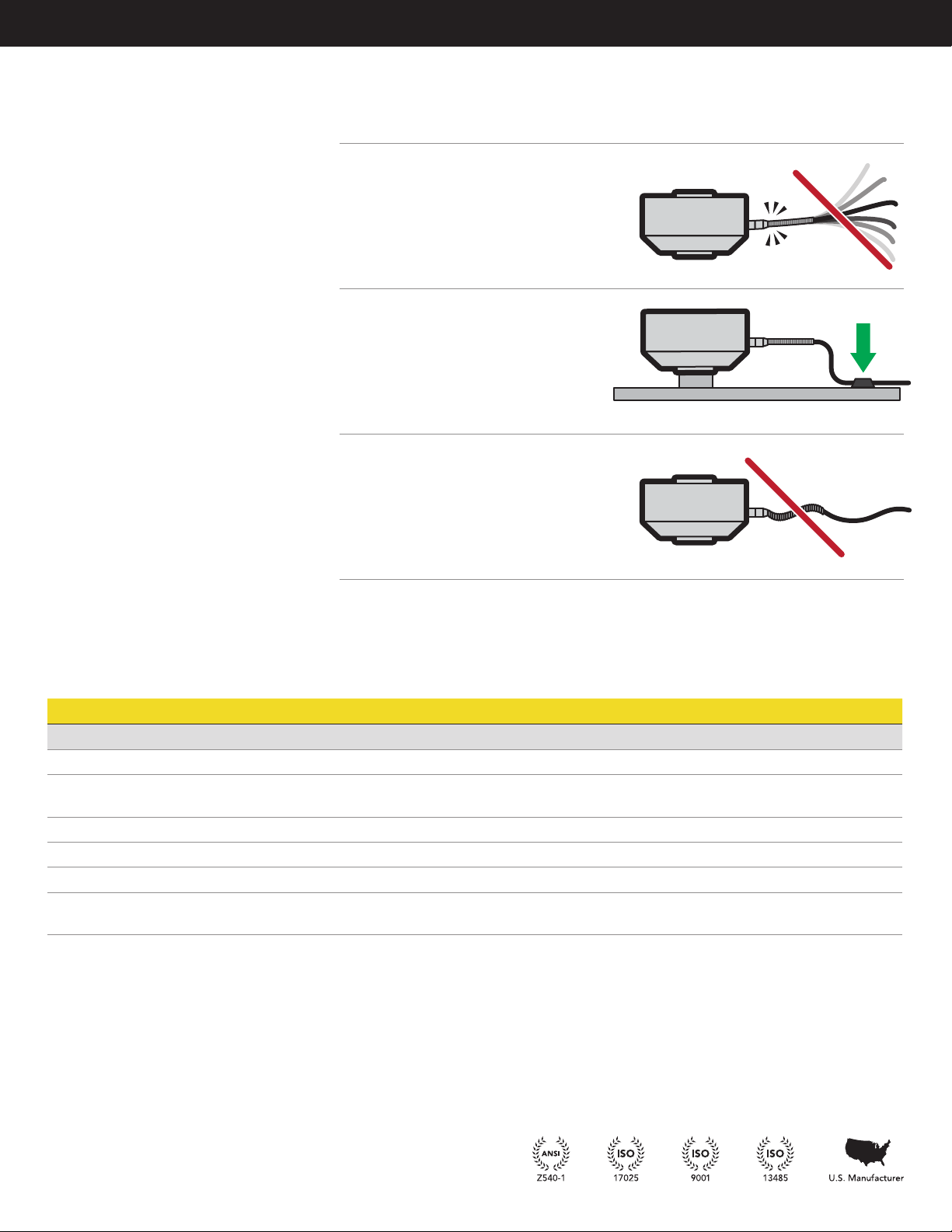

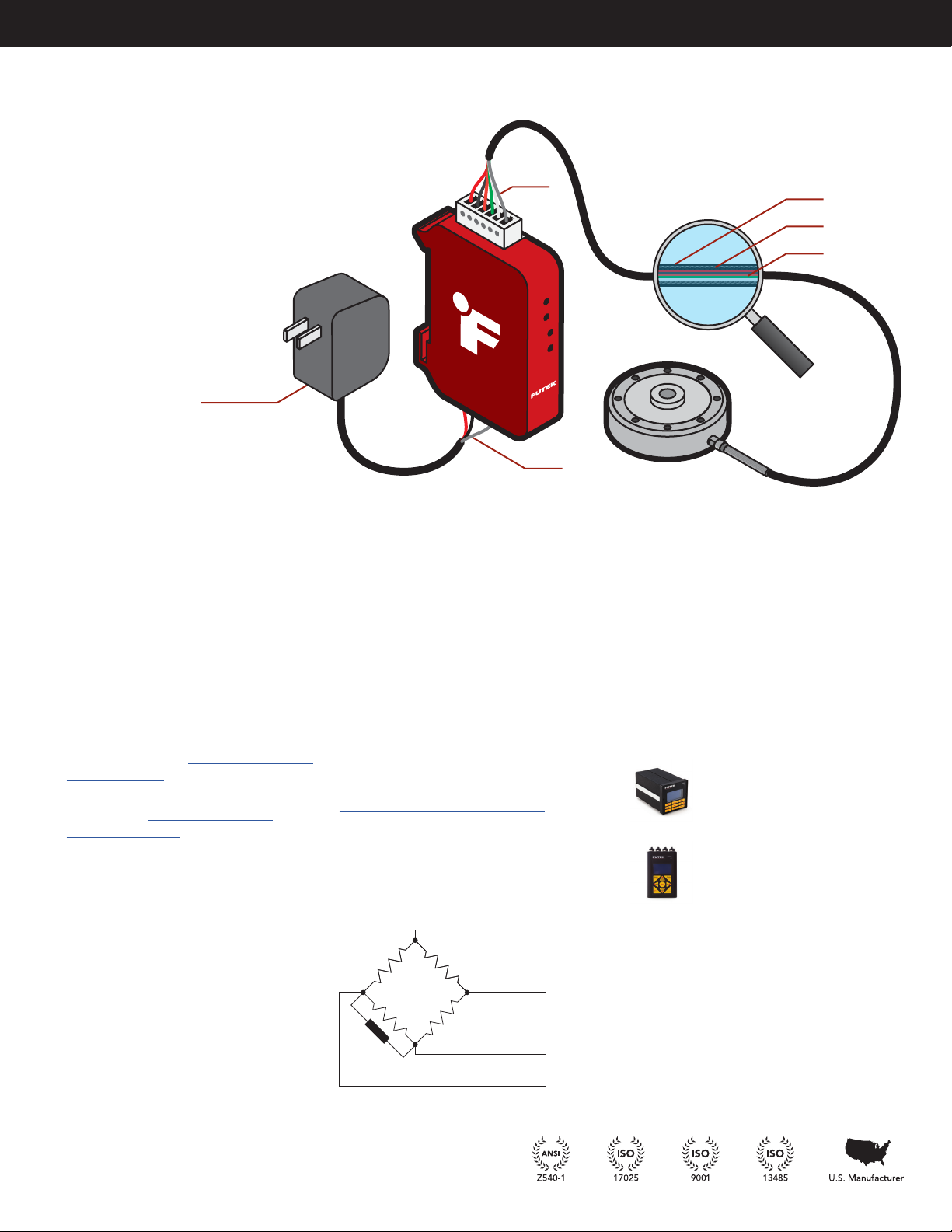

Shield Usage and Connections

• Cable shielding should be grounded on one

end, either the sensor side or instrument

side to avoid ground loops.

• A shield connection listed as floating on a

sensors spec sheet means the cable shield is

not connected on the sensor side and may

be connected on the instrument side

to ground.

Calibration

• A yearly calibration is recommended. But

verification and calibration period shall be

defined based on application, conditions,

endurance and usage.

• FUTEK offers NIST calibrations as well

as A2LA accredited calibrations for total

uncertainty.

• For more information on available

calibrations visit FUTEK calibration web

page at: http://www.futek.com/calibration-

services.aspx

• For recalibration orders visit the FUTEK

recalibration page at: http://www.futek.com/

recalibration.aspx

• An online summary of calibration results

is available at: http://www.futek.com/

calibrationData.aspx

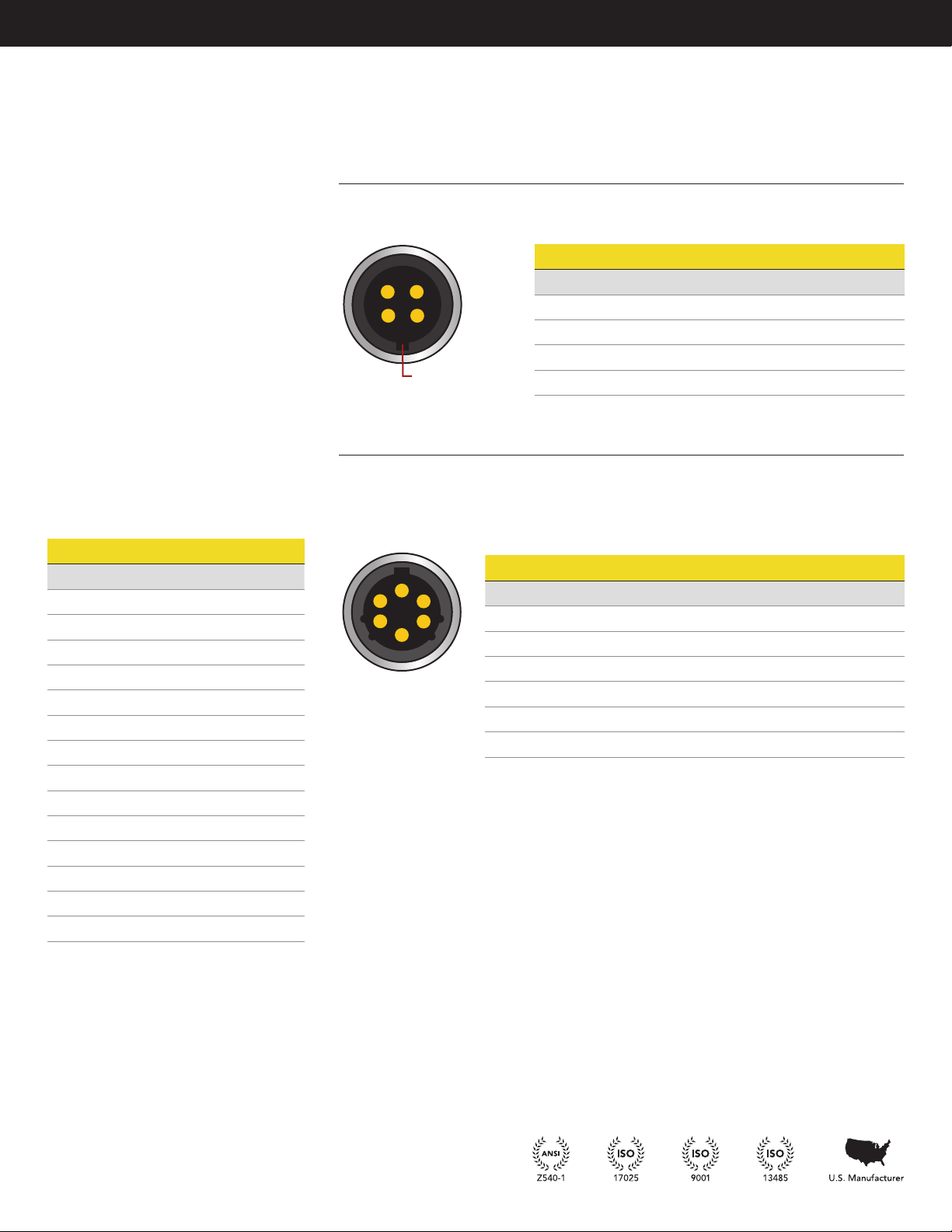

SHUNT

A shunt is an external resistance applied across

two points on the load cell’s Wheatstone

bridge to generate a known, fixed output from

the sensor.

Shunt results can be used to set up instruments

as well as compare changes to the load cell

output over time and usage.

When selecting the appropriate shunt

resistance for your load cell, we recommend a

resistance that generates an output of about

80% of the sensor’s rated output. It is important

to have a shunt resistance that results in an

output that is less than the full output of the

load cell.

An online shunt calculator can be found at

http://www.futek.com/shuntcalc.aspx to find

a resistance that will generate a certain shunt

output level, or to estimate the output for a

known shunt resistance.

Additionally, recommended shunt resistance

levels may be available on the sensor spec

sheet.

TEDS

Transducer Electronic Data Sheet (TEDS)

IEEE1451.4 standard is available for FUTEK

sensors and is utilized by select FUTEK

instruments.

Through the use of TEDS load cell calibration

information can be stored with sensor, or

sensor cable, for use with TEDS capable

instruments.

FUTEK utilizes the Bridge Sensor template 33

for the LCF family.

The following FUTEK instruments are TEDS and

LCF compatible:

IPM Series

Panel Mount Display

IHH Series

Handheld Instrument

Bridge Sensor

XXXΩ

+ Excitation

+ Signal

Shunt Cal

– Signal

– Excitation

Shield

Power Supply

Shield Jacket

Shield

Wires