TFF Torque Sensor Family Manual 10

Sensor Solution Source

Load · Torque · Pressure · Multi-Axis · Calibration · Instruments · Software

www.futek.com

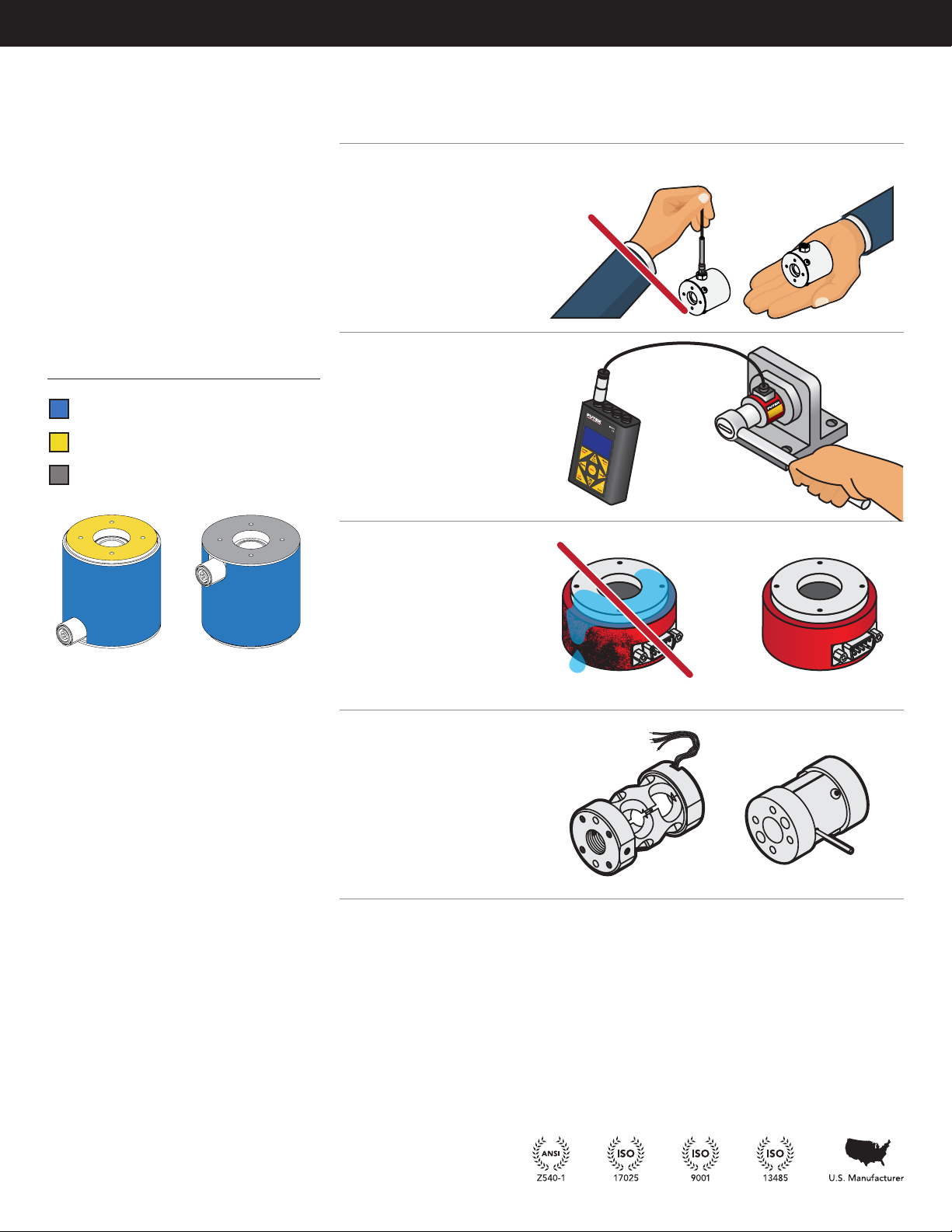

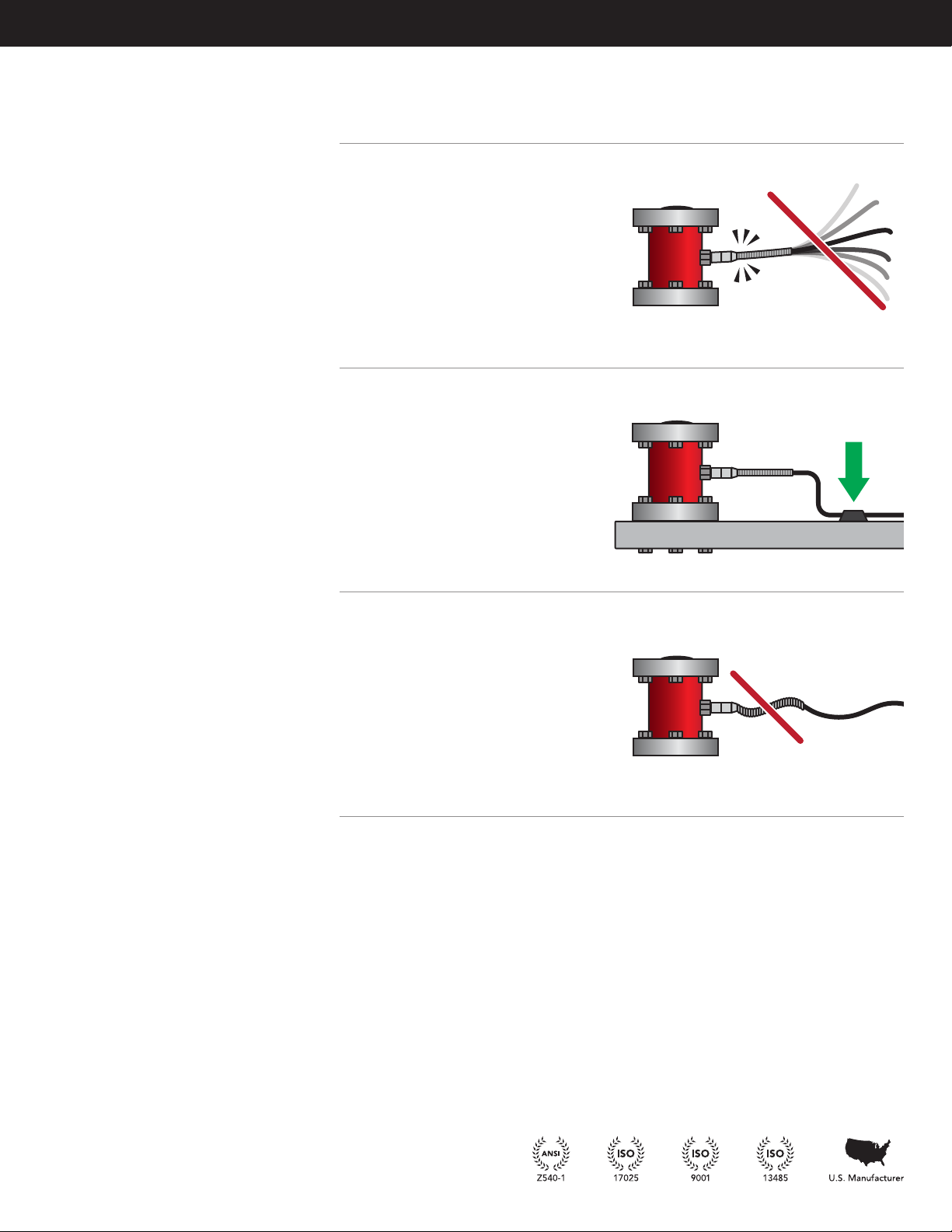

Troubleshooting

When troubleshooting, we recommend that the sensor be removed from any fixtures. In order to confirm that that sensor

is operating correctly, we suggest placing the sensor on a firm surface, and to apply a known load.

We also recommend using a volt meter with a clean power supply to confirm the sensor is operating correctly.

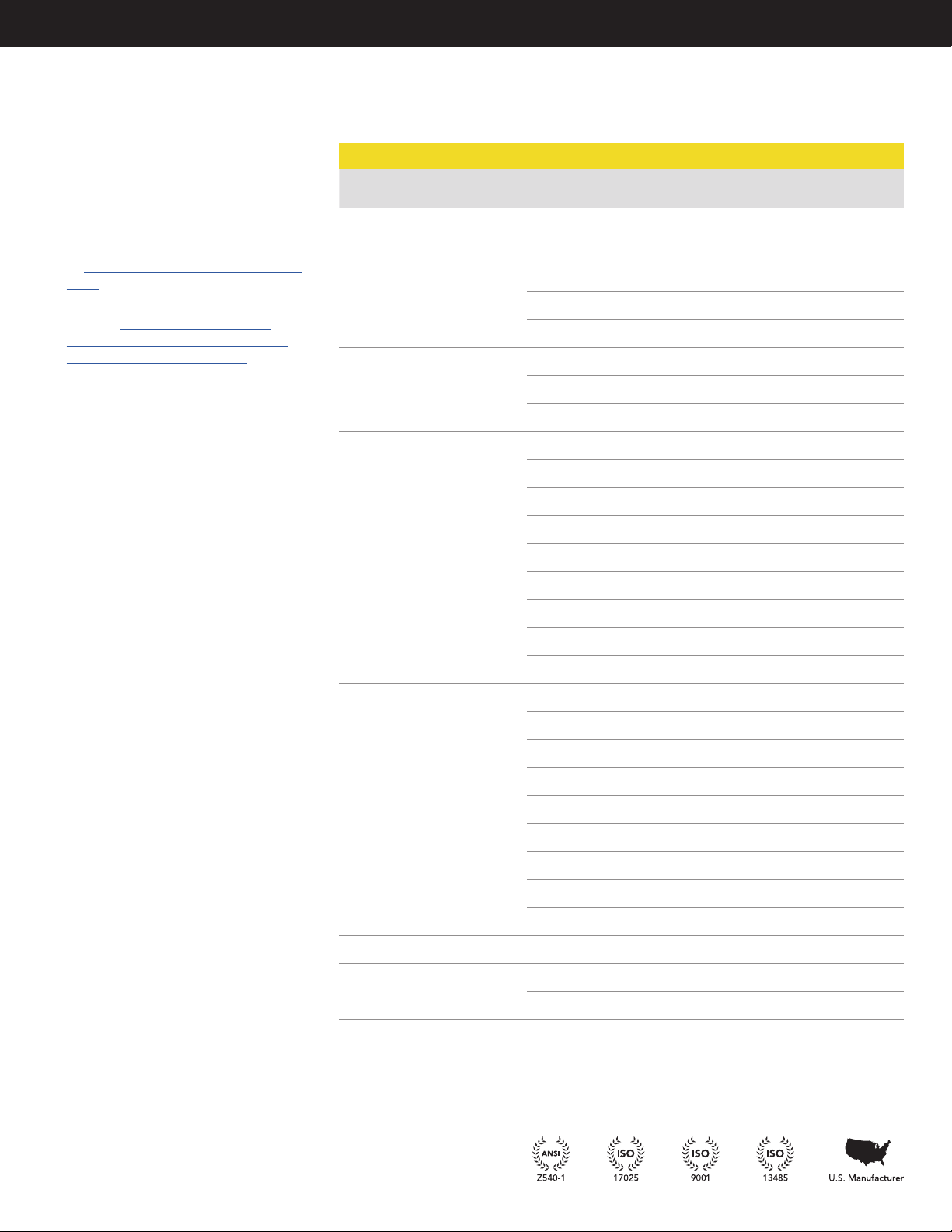

SYMPTOM POSSIBLE CAUSE CHECK REPAIRABILITY

High zero output • Sensor is under preload

• Sensor has been overloaded from too

much load, off axis load, or moment.

• Fixtures or bolting stress for causes of

pre-load.

• Loading and support placement for off

axis loads.

• Avoid excessive moments during

installation.

• Overload shift would not be repairable.

• If zero offset is stable it may be

possible to use sensor by use of Tare

or subtracting zero from sequential

readings.

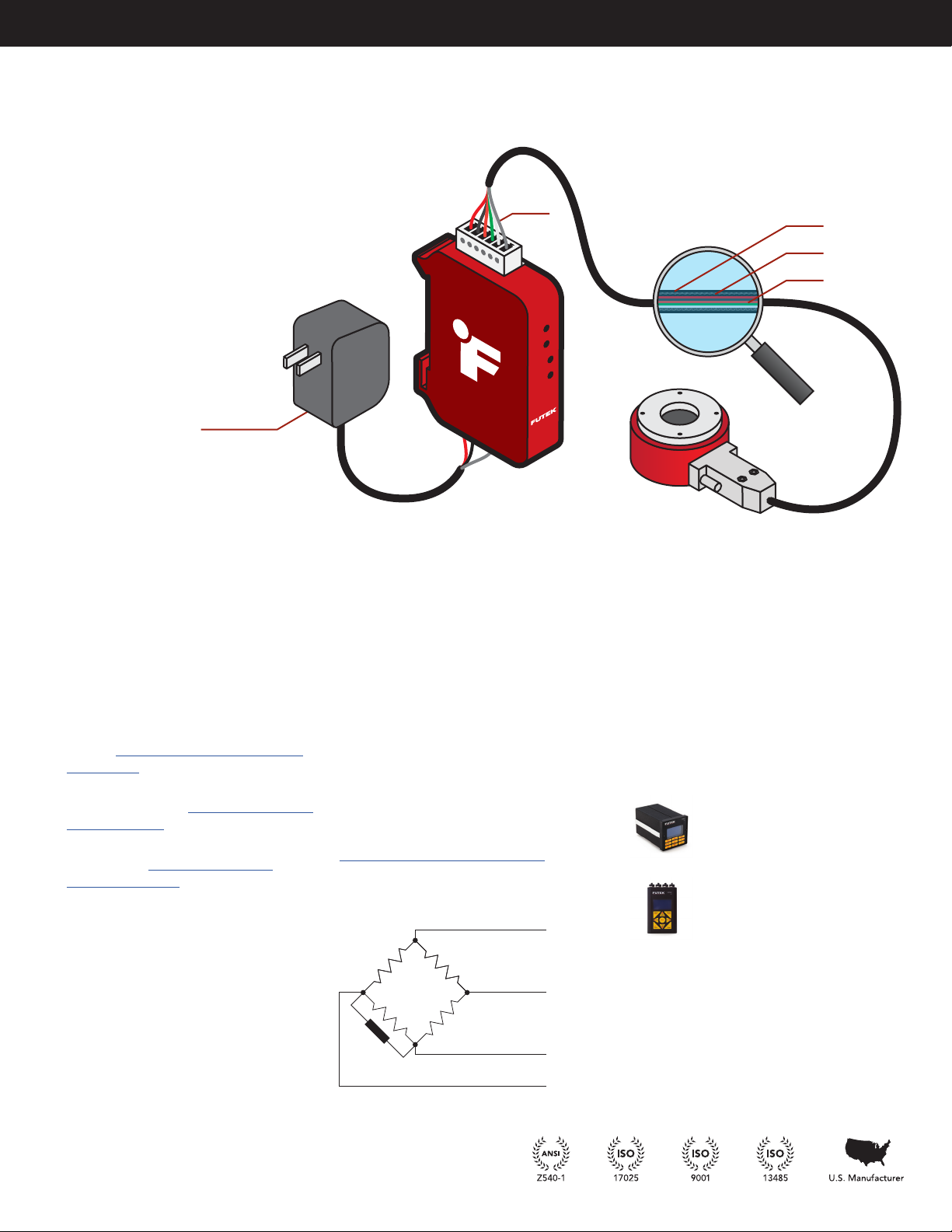

Non-responsive

zero output

• Sensor or instrument is not powered.

• Sensor is not properly connected.

• Load is not displaced properly onto

sensor.

• Sensor is not supported correctly and

not allowing deflection to occur to

measure load.

• Internal disconnect or short.

• Power and wiring to sensor and instru-

ment.

• Sensor bridge resistance for possible

opens or shorts.

• Perform continuity test on cable.

• Load is placed correctly on sensor

loading surface.

• Sensor loading surface is not obstruct-

ed or supported and able to flex under

load.

• Sensor support is not giving while

sensor is loaded.

• Internal disconnections or shorts would

not be available for repair.

• Sensor cable repair may be available

if disconnect or short is not too close

to sensor.

Non-responsive

high output

• Sensor is disconnected from

instrument.

• An opening has occurred in sensor or

cable connection.

• Sensor has been overloaded and de-

formed causing permanent high stress

on internal gauges.

• Fixture, applied load, or mounting is

causing a high pre-load on sensor.

• Power and wiring to sensor and instru-

ment.

• Sensor bridge resistance for possible

opens or shorts.

• Perform continuity check on cable.

• Sensor zero output to see if sensor

returns to zero or has a high zero load

output due to overloading.

• Remove load and loosen mounting

bolts or fixtures to check if sensor is

being preloaded.

• Overload shift would not be repairable.

• Internal disconnections or shorts would

not be available for repair.

• Sensor cable repair may be available

if disconnect or short is not too close

to sensor.

Incorrect output for

applied load

• Load is not applied correctly to sensor

loading surface or is off axis.

• Fixtures are not secure or obstruct

loading.

• Sensor loading surface is not able to

deflect with applied load.

• Sensor support is not ridged and firm.

• Incorrect sensor output is utilized.

• Placement of load on sensor.

• Fixtures are not impeding ability to

load.

• Support surface is not giving with

applied load.

• Calibration verified outputs are being

used.

• Recalibration is available for confirma-

tion of sensor performance.