sect. 50 00-02-1010

rev. 2021/07/21

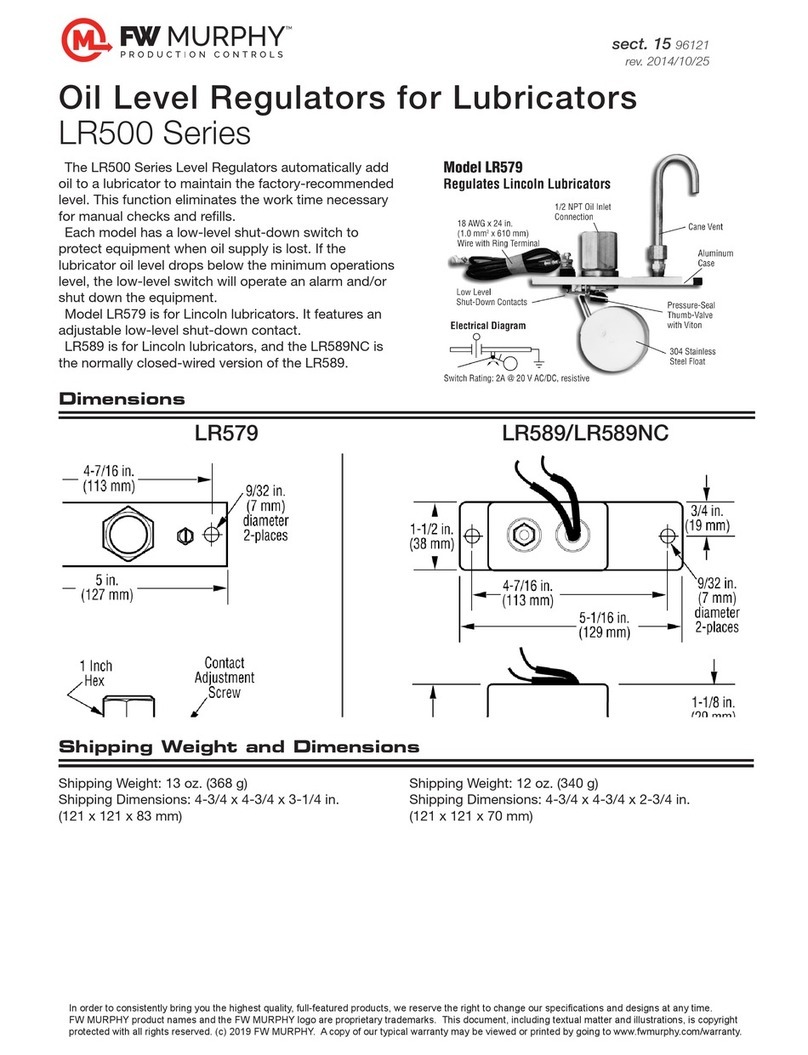

Fender washer

with star nut

on top stud

(option)

5/16” star nuts on three studs

How to Replace LCDT with TTD

In this LCDT replacement conguration, the TTD will not carry a NEMA 4 rating due to the mounting stud removal mentioned in

the installation section below.

Hazardous Area Classification

The TTD has CSA Class I, Division 2, Groups B, C and D approval. This differs from LCDT which has CSA Class I, Division 1,

Group D approval. Consult with your AHJ for a review of classication for the area where the LCDT is installed for verication

that it may t into Class I, Division 2 classication.

Certification

Please read the Installation & Operation manual for the TTD. This will familiarize you with the new features and congurability

available in the TTD.

LCDT mounting holes circled

Catalog Subsection for Table of Contents

95026 Product Name for Catalog Table of Contents

Remove the

circled TTD

mounting

studs.

Installation

1. The TTD-2 model (part # 50700601) offers exact drop-in

replacement option for both models of LCDT-NO and

LCDT-NC.

a. Systems powered by 12- or 24-VDC (battery powered)

or CD negative ground ignition are fully compatible.

b. Systems powered by 120-VAC line voltage will require

a 24-VDC power supply installed to power the TTD.

c. CD positive ground ignition systems are not supported

by TTD.

2. This guideline is for typical installations with fuel valve,

ignition and power input connection changes and are

meant to supplement the TTD installation diagram 50-08-

0718.

a. Refer to the drawing in the TTD Installation &

Operation manual for clarication on your specic

installation.

b. To nd all information about TTD features and options

as well as the downloadable installation & operations

manual, go to https://www.fwmurphy.com/products/

controllers/ttd.

3. Mount the TTD head.

a. Only three (3) of the TTD mounting studs are used to

mount to the original LCDT mounting holes.

b. On the TTD, remove the mounting studs (5) circled

below. Use pliers to turn them counterclockwise to

unscrew from the bezel. Removing studs in this matter

will not affect warranty of the TTD.

c. Align the TTD studs with the 2 bottom holes and insert

into the LCDT opening. They will t into the old holes.

The top center stud will be on the top edge of the

cutout.

d. Install a star nut on the bottom studs rst, then on

the top center stud. The top center nut will catch

the edge of the sub panel plate as shown below. For

vibration or stability concerns a 5/32” x 7/8” stainless

fender washer is recommended.

e. Tighten the three 5/16” star nuts to 9 in. lbs. (1 Nm).