3

Expert PDU Energy 8340/8341 © 2021 GUDE Systems GmbH

Table of contents

1. Device Description 5

1.1 Security Advice ....................................................................................................... 6

1.2 Content of Delivery ................................................................................................. 6

1.3 Description ............................................................................................................. 6

1.4 Installation ............................................................................................................. 7

1.5 Hotswap Drawer ..................................................................................................... 8

1.6 Technical Specifications .......................................................................................... 9

1.6.1 Electrical Measurement ........................................................................................... 9

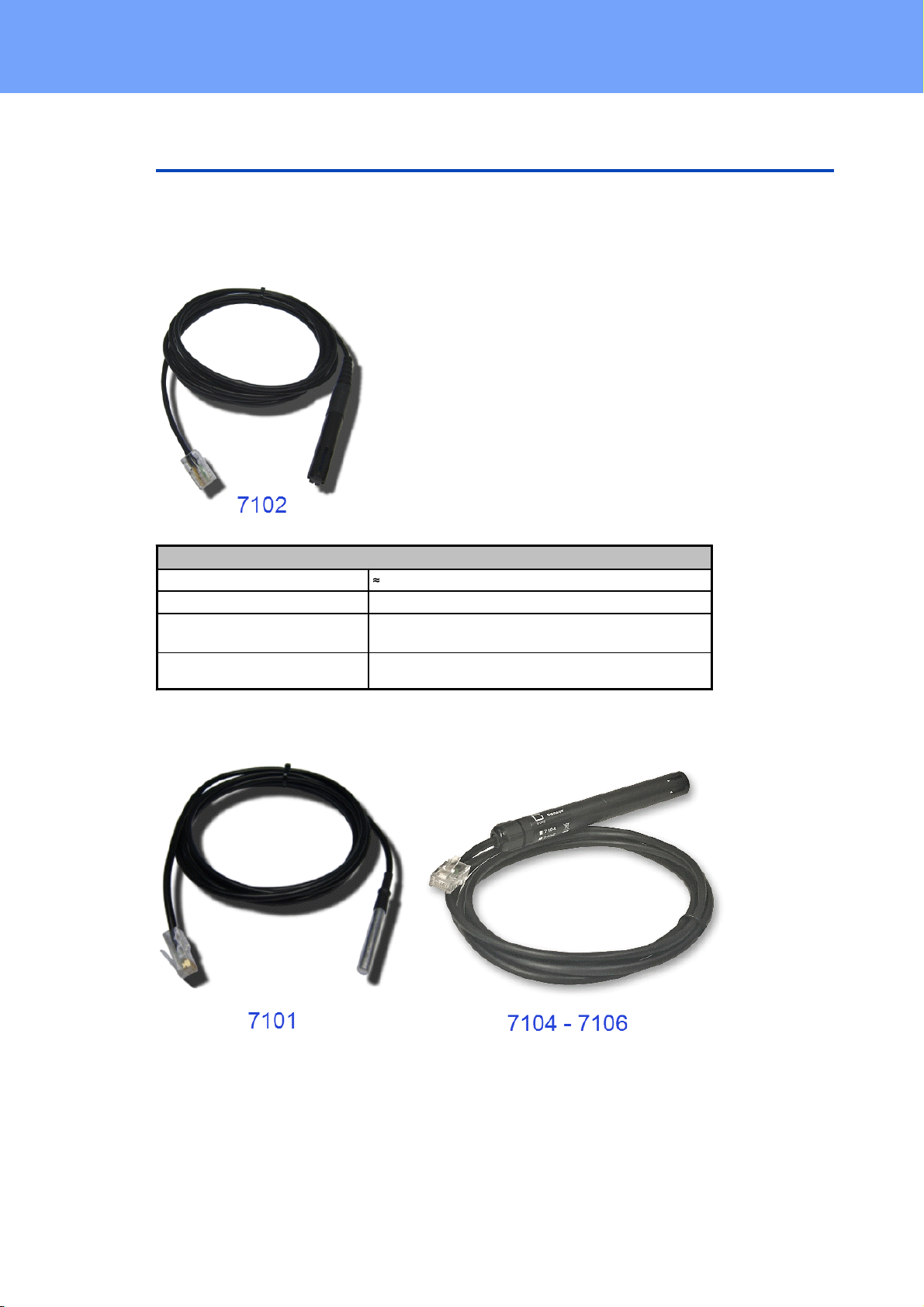

1.7 Sensor .................................................................................................................. 10

2. Operating 13

2.1 Operating the device directly ................................................................................ 14

2.2 Control Panel ........................................................................................................ 14

2.3 Maintenance ........................................................................................................ 15

2.3.1 Maintenance Page ................................................................................................. 16

2.3.2 Configuration Management .................................................................................. 18

2.3.3 Bootloader Activation ............................................................................................ 19

3. Configuration 21

3.1 Ethernet ............................................................................................................... 22

3.1.1 IP Address ............................................................................................................... 22

3.1.2 IP ACL ..................................................................................................................... 24

3.1.3 HTTP ....................................................................................................................... 25

3.2 Protocols .............................................................................................................. 26

3.2.1 Console ................................................................................................................... 26

3.2.2 Syslog ..................................................................................................................... 27

3.2.3 SNMP ...................................................................................................................... 27

3.2.4 Radius ..................................................................................................................... 29

3.2.5 Modbus TCP ........................................................................................................... 30

3.2.6 MQTT ...................................................................................................................... 31

3.3 Clock ..................................................................................................................... 32

3.3.1 NTP ......................................................................................................................... 32

3.3.2 Timer ...................................................................................................................... 33

3.3.3 Timer Configuration ............................................................................................... 33

3.4 Sensors ................................................................................................................. 40

3.5 E-Mail ................................................................................................................... 41

3.6 Front Panel ........................................................................................................... 42

4. Specifications 43

4.1 Automated Access ................................................................................................ 44

4.2 Messages .............................................................................................................. 44