FITING

The wall on which the water heater is installed must be able to support the weight of the

apparatus when full of water. In the event that the wall is resistant but thin, guard-plates

must be used on the other side of the wall.

Attach the water heater with 10 mm diameter wall-plugs and screws attached to the wall

beforehand. The outline printed on the packaging aids the positioning of the screws.

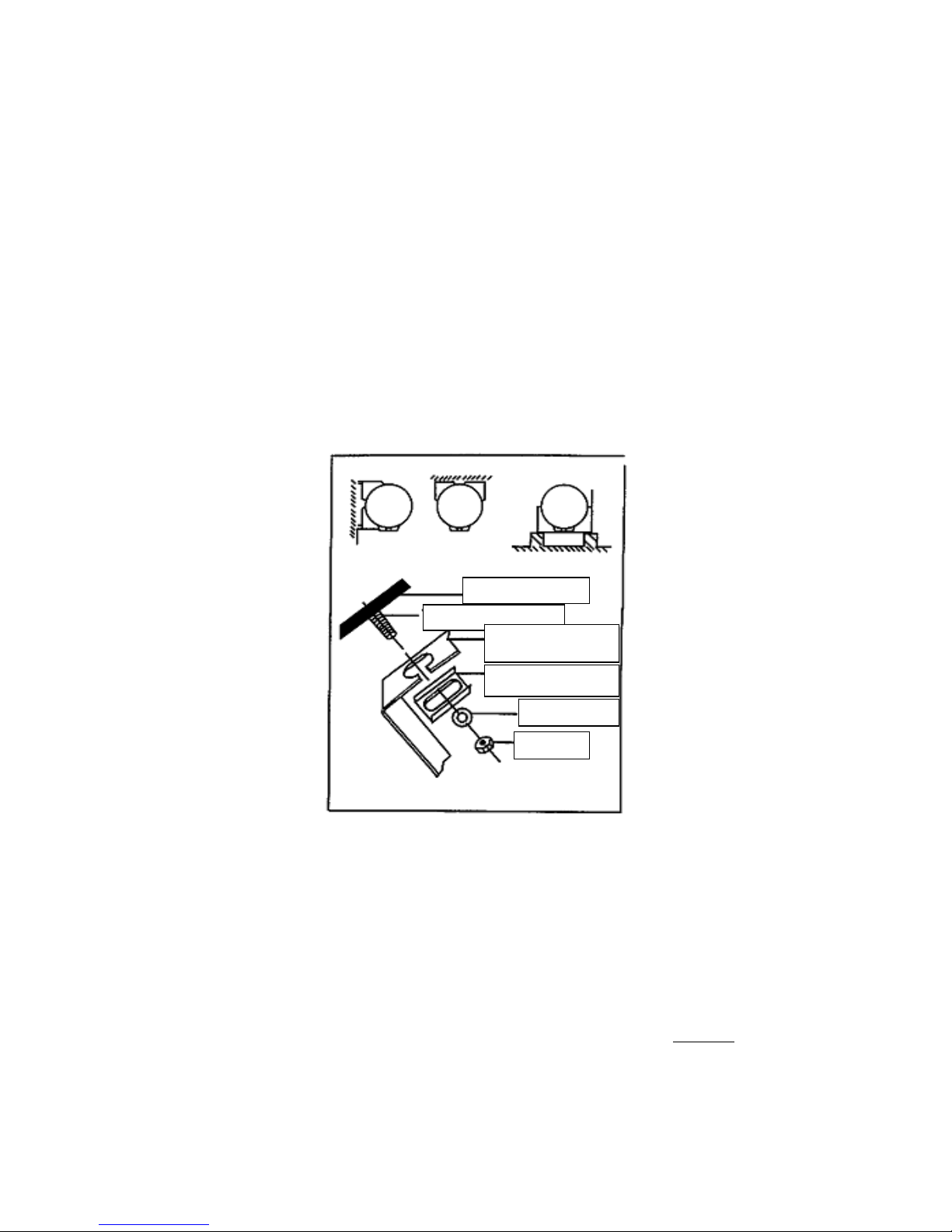

The attachment supports are in the polystyrene packaging. For round water heaters,

screw the supports of the apparatus directing the notches of the supports downwards.

(Warning: do not place metal nuts on the screws).

Vertical walls: In order to make it possible to replace the heating element at a particular

moment in time, leave a free space where the heating element is positioned of at least

250 mm (GTV 75 L), 300 mm (GTV 100 L, GTE 30 L and GTE 50 L), 390 mm (GTV

150 L) and 480 mm (GTV 200 L).

Horizontal: there are 3 possibilities for installation:

WARNING! Once the water heater is in place, the water entry and exits tubes must be

in a vertical position below the water heater. Leave free space in the heating element of

a minimum of 400 mm.

HYDRAULIC CONNECTION

Before making the hydraulic connection, it is essential to clean the entry tubes in order

to prevent the entry of metal and foreign particles into the water heater. Warning: Never

connect the water entry and exit points directly to the tubing because this would cause

galvanic pairs that generate corrosion. It is compulsory to employ anti-electrolytic pipe

couplings on the entry points. If there were corrosion in the tank and the apparatus had

no pipe couplings, the guarantee would be invalidated.

WALL OR CEILING

ATTACHMENT

ATTACHMENT

SUPPORT

ATTACHMENT PIECE

WASHER

NUT