Page | 2

TABLE OF CONTENTS

SECTION 1 — INTRODUCTION................................................................................................................. 4

Abbreviations ..................................................................................................................................4

Symbol List .....................................................................................................................................4

Definitions .......................................................................................................................................5

GeneralSafetyPrecautions..............................................................................................................6

ElectricalSafety Precautions...........................................................................................................7

SECTION 2 — DECOTECH™ SOLAR SYSTEM OVERVIEW ............................................................................ 9

Main Components of the DecoTech™ Solar System......................................................................9

DecoTech™ Solar SystemParts....................................................................................................10

Array Configurations.....................................................................................................................12

Grounding......................................................................................................................................12

SECTION 3 — DECOTECH™ SOLAR SYSTEM CONSIDERATIONS AND REQUIREMENTS................................15

Design Considerations...................................................................................................................15

Installation Requirements..............................................................................................................17

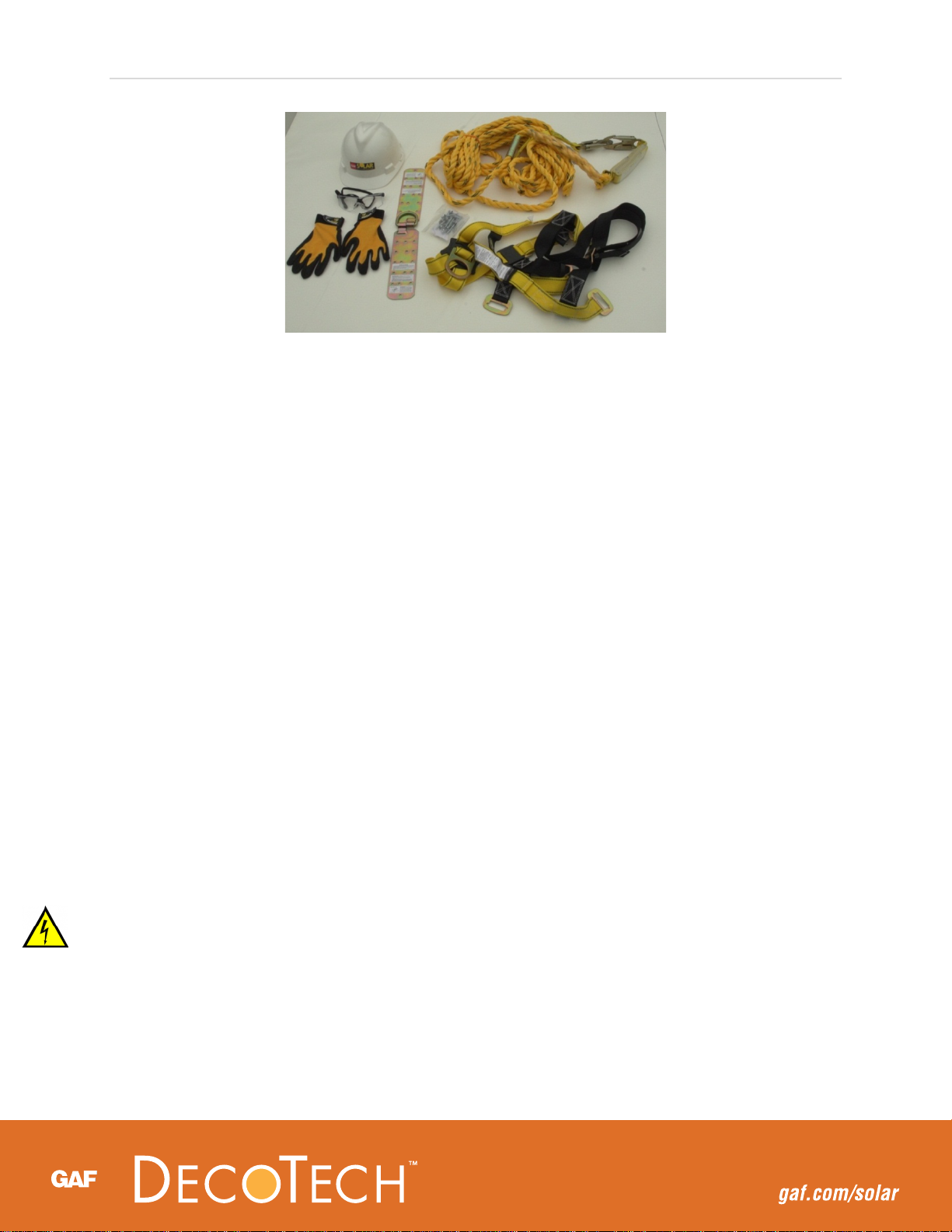

Recommended Tools.....................................................................................................................18

Prior to Installation........................................................................................................................19

SECTION 4 — DECOTECH™ SOLAR SYSTEM INSTALLATION ......................................................................20

Step 1: Build the Solar Module Assembly ....................................................................................21

Step 2:Prep the Roof.....................................................................................................................25

Step 3: Install the Starter Bar.........................................................................................................31

Step 4: Install the First Row of Solar Module Assemblies ...........................................................33

Step 5: Install Remaining Solar Module Assemblies in the Solar Array......................................37

Step 6: Install Side Flashings ........................................................................................................38

Step 7: Install Top Flashings.........................................................................................................41

Step 8: Top Flashing Weatherization and Shingle Integration......................................................46

SECTION 5 — WIRING, LABELING, AND MONITORING.......................................................................49

Wiring............................................................................................................................................49

Solar System Safety Labels...........................................................................................................50

Monitoring.....................................................................................................................................51

SECTION 6 — DECOTECH™ SOLAR SYSTEM MAINTENANCE.....................................................................52