Pin Nose Gages and Seal Gage Operation Manual

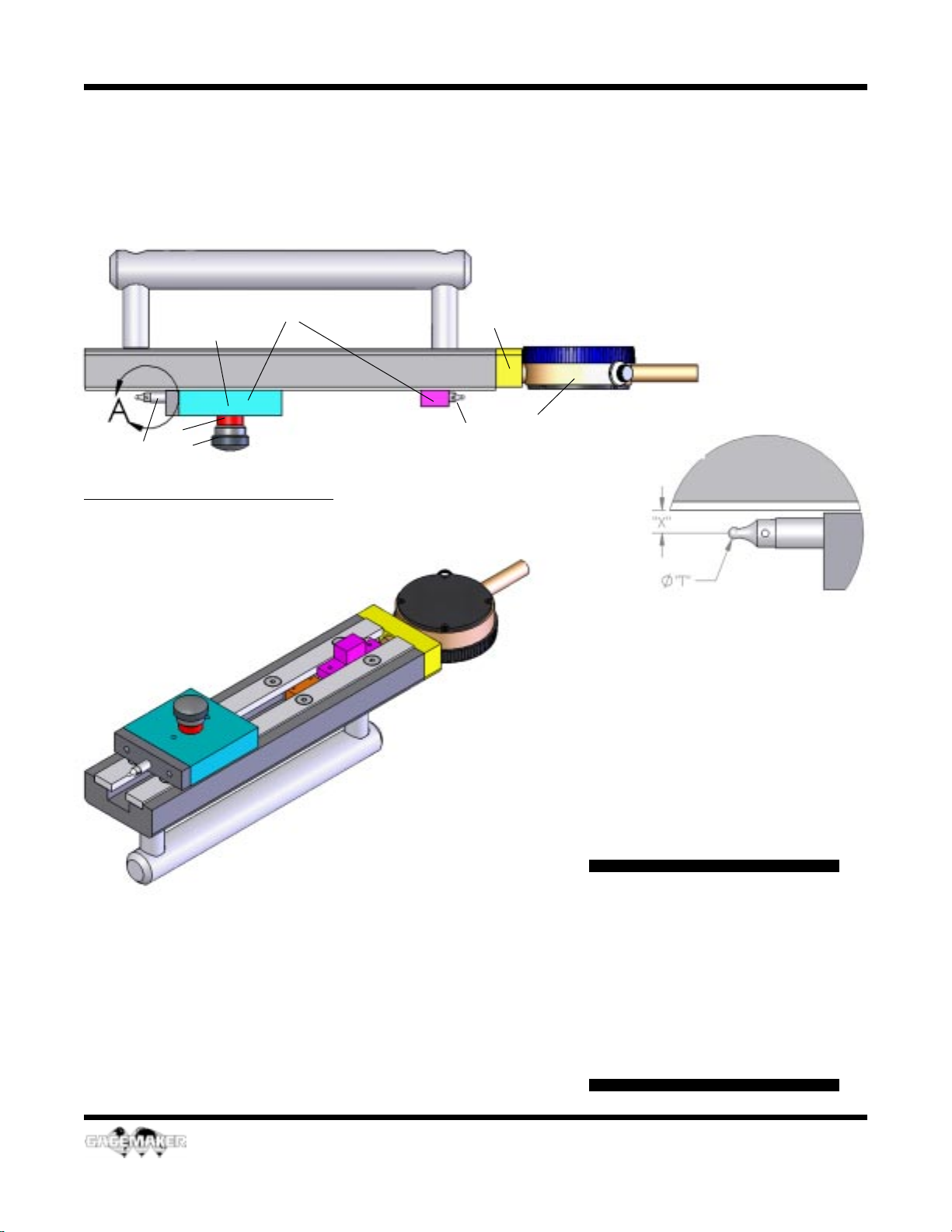

ThePin Nosegages measurecritical pinseal diametersand widths.These gagesadjust

to cover all sizes ofseal diameters. The standard pin nose gage measures seal

diameters from 2 3/8” – 13 3/8”.

ThePin Nose can be used to measurestraight ortapered seal diameters, shallow bores,

andholelocations.

The pin nose gages use precision contact points to accurately measure the ring groove

diameter and width at the critical sealing point of the face groove.

Before inspecting parts, the pin nose gages must be preset to a nominal predetermined

dimension. The Seal Inspection Tolerances and Setting Dimension tables in this manual

determine the gage’s setting dimensions and gauging tolerances. The pin nose gages can be

preset using gage blocks, Frame Standards, or Gagemaker’s Pin Nose Diameter Gage

SettingMaster.

To inspect parts, the contact points are placed in the seal of the part and the gage is

positioned by sweeping to obtain an indicator reading. Gage indicators show actual deviation

from the preset master dimension. Taking measurements in several different locations along

the seal will provide an average seal diameter or width. It is also recommended that the gage

be zeroed periodically during use to maintain accurate readings.

Technical Support

Phone: 713-472-7360

Hours: Monday – Friday 8AM – 5PM (CST)

Product Information and Updates

Visit our web site at: www.gagemaker.com

INTRODUCTION

5