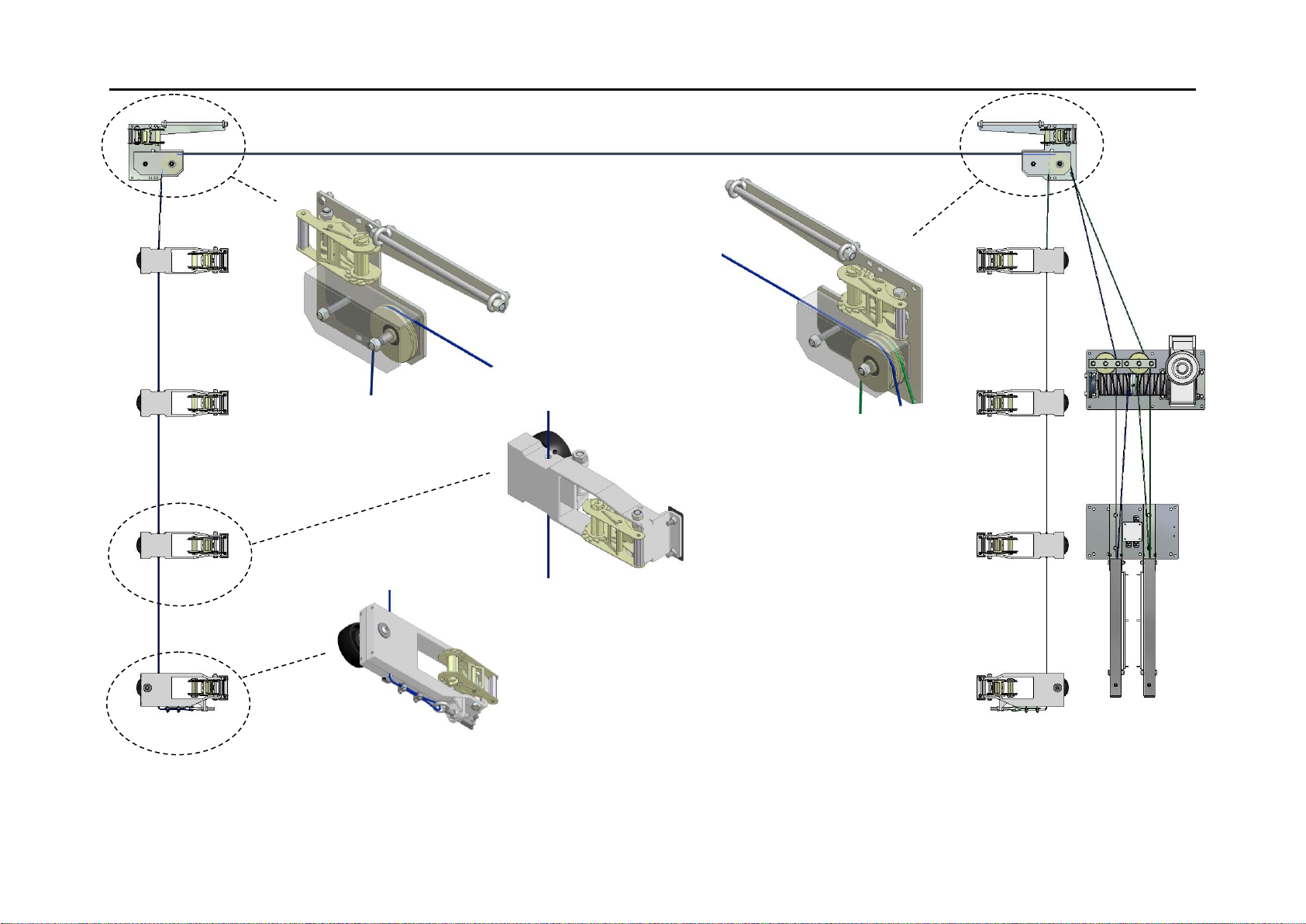

Electrics

Only allow qualified electricians to work on the electrical connections of the door.

This document covers the key instructions with regards to bringing the Electric Drive

into service. Read the additional information from the supplier of the Electrical

Motor and Control Box for full installation instructions.

Items Required by Installer

Two personnel with a standard tool kit including:

•Allen key set: 3mm to 8mm

•8mm socket or spanner for Cable Grips

•Electric drill

•Wire cutters and self adhesive PVC tape

•Sharp pair of scissors or knife

•Spirit level

•M10 Bolts for fixing Electric Drive and Counterweight Plates to Brackets up to

30mm thick are supplied.

•M6 Bolts for fixing Chain Keep to Brackets up to 30mm thick are supplied.

•Two packers for Trolleys, 150mm to 250mm tall (wood, brick etc.)

•Boom or Scissor lift to reach top of opening

•Power supply with LOCKABLE isolator within 1m of the Electric Drive.

Single Phase = 230V, 750W, 5.2 Amps

Three Phase = 400V, 1500W, 3.2 Amps

•Clips to fix Electric Wires to the Building

Key Instructions

CAUTION: Potentially hazardous situation: must be avoided otherwise

injuries may result.

ATTENTION: Observe the given instructions otherwise the product or

adjacent items may be damaged

NOTE: Helpful comments and information to assist in installation or use of your

product