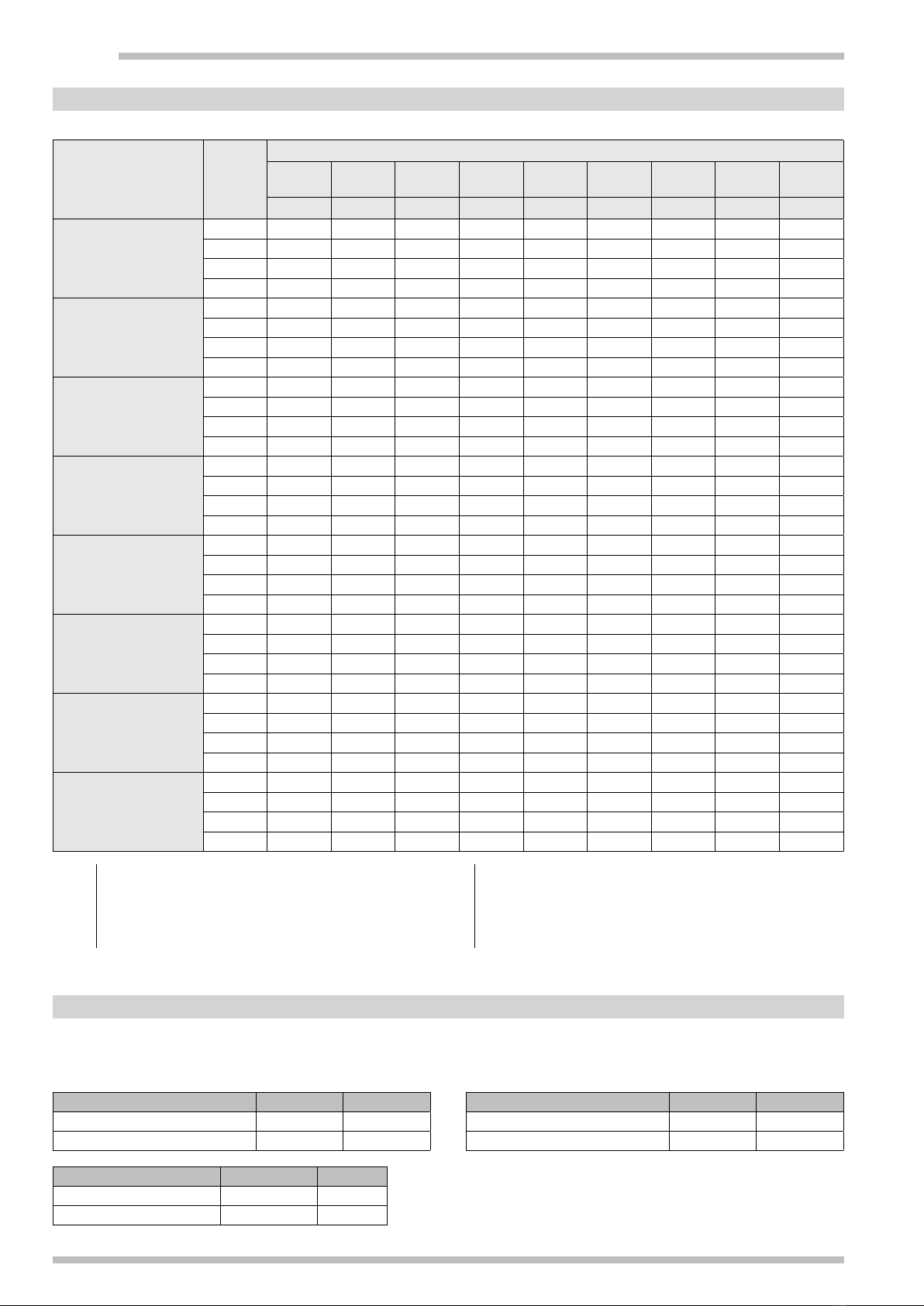

IWCi

IWCi Vr

Lw

125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz 8000 Hz LwA LpA

dB dB dB dB dB dB dB dB/A dB/A

IWCi O32

1 36,1 33,9 25,3 19,7 21,4 16,8 20,0 30,0 25,0

2 42,5 43,4 41,5 32,2 27,0 18,5 19,8 41,0 36,0

3 46,1 46,7 44,0 36,3 29,9 19,9 20,4 44,0 39,0

4 46,7 47,7 45,9 39,8 33,2 22,6 17,7 46,0 41,0

IWCi O34 DF

1 36,1 33,9 25,3 19,7 21,4 16,8 20,0 30,0 25,0

2 42,5 43,4 41,5 32,2 27,0 18,5 19,8 41,0 36,0

3 46,1 46,7 44,0 36,3 29,9 19,9 20,4 44,0 39,0

4 46,7 47,7 45,9 39,8 33,2 22,6 17,7 46,0 41,0

IWCi 042

1 43,0 33,9 29,0 21,8 19,2 15,9 19,9 32,0 27,0

2 48,3 50,3 48,2 40,7 33,6 23,3 18,8 48,0 43,0

3 49,7 51,9 51,0 44,6 38,1 29,4 19,1 50,8 46,0

4 51,6 55,1 54,8 50,0 44,4 37,7 22,8 55,2 50,0

IWCi 044 DF

1 43,0 33,9 29,0 21,8 19,2 15,9 19,9 32,0 27,0

2 48,3 50,3 48,2 40,7 33,6 23,3 18,8 48,0 43,0

3 49,7 51,9 51,0 44,6 38,1 29,4 19,1 50,8 46,0

4 51,6 55,1 54,8 50,0 44,4 37,7 22,8 55,2 50,0

IWCi 052

1 37,4 42,6 41,1 34,8 27,9 19,4 13,4 41,0 36,0

2 49,4 54,6 53,0 46,8 39,9 31,4 21,5 53,0 48,0

3 52,7 57,2 56,6 51,8 45,7 38,4 25,2 57,0 52,0

4 56,8 60,4 60,1 56,3 50,9 44,2 31,2 61,0 56,0

IWC 062

1 49,3 45,7 41,2 37,5 28,0 21,0 20,5 43,0 38,0

2 48,1 49,8 47,5 42,8 32,8 21,0 20,2 48,0 43,0

3 49,5 51,9 47,8 42,7 37,8 28,5 17,5 49,0 44,0

4 51,4 53,9 49,8 44,7 39,8 30,5 21,7 51,0 46,0

IWC 082

1 40,2 40,0 35,5 31,0 23,0 19,3 19,6 37,0 32,0

2 46,8 48,9 44,0 41,3 31,9 22,5 19,7 46,0 41,0

3 50,8 52,6 48,2 45,4 36,9 27,4 19,7 50,0 45,0

4 53,8 55,6 51,2 48,4 39,9 30,4 20,5 53,0 48,0

IWC 102

1 45,4 45,3 39,6 39,7 27,4 21,4 20,8 43,0 38,0

2 50,0 51,2 46,1 44,9 37,8 28,5 21,3 49,0 44,0

3 52,5 54,1 50,2 49,3 42,3 35,0 21,1 53,0 48,0

4 56,5 58,1 54,2 53,3 46,3 39,0 27,3 57,0 52,0

8It is strictly forbidden to reproduce this manual, even partially WC66000122 - Rev 03

5. SOUND LEVELS

IWCi 3-4-5-6-8-10, 2 PIPES

NET WEIGHT

Model IWCi 3 IWCi 4-5

Unit 18 kg 20 kg

Facade / grille assembly 2,5 kg 2,5 kg

6. OVERALL FOOTPRINT

IWCi 3-4, 4 PIPES

NET WEIGHT

Model IWCi 3 IWCi 4

Unit 18 kg 20 kg

Facade / grille assembly 2,5 kg 2,5 kg

Vr Ventilation speed:

max 4, med 3, min 2, smin 1

LwAGlobal A-weighted sound power level

Lw Unweighted sound power level for octave band LpAGlobal A-weighted sound pressure level, calculated at a distance of

1m with direction factor of 4

Model IWCi 6 IWCi 8-10

Unit 23 kg 29 kg

Facade / grille assembly 5 kg 7 kg