LEP

Page 7 of 28

RG66007652– Rev.01

Compressors: only prime international brand Scroll compressors are used on the LEP units.

The Scroll compressor is the best solution today in terms of reliability and efficiency in the

range of power outputs up to 182 kW for each circuit and the best solution in terms of emitted

sound output. N.B.: Scroll compressors, just like all air-tight compressors, are classified as

pressure recipients in compliance with PED for that which regards the low pressure section to

which the PS indicated on the data plate refers.

Heat exchangers: only brazed plate heat exchangers are used, made of austenitic stainless

steel AISI 304 with AISI 304 L connections, featured by a reduced carbon content to simplify

brazing operations. The solution of the brazed plate heat exchanger represents the state-of-

the-art in terms of thermal exchange efficiency and allows a strong reduction of refrigerant

load compared to standard solutions. The high degree of turbulence induced by the internal

corrugation of the plates together with their perfect smoothing features, makes it difficult for

filth to deposit or for limestone to build up on the condenser side. N.B.: due to thermal

insulation, the data plate in compliance with 97/23 PED is not legible, but the serial number of

the heat exchanger and the declaration of conformity are detected during production and are

an integral part of the HiRef archive.

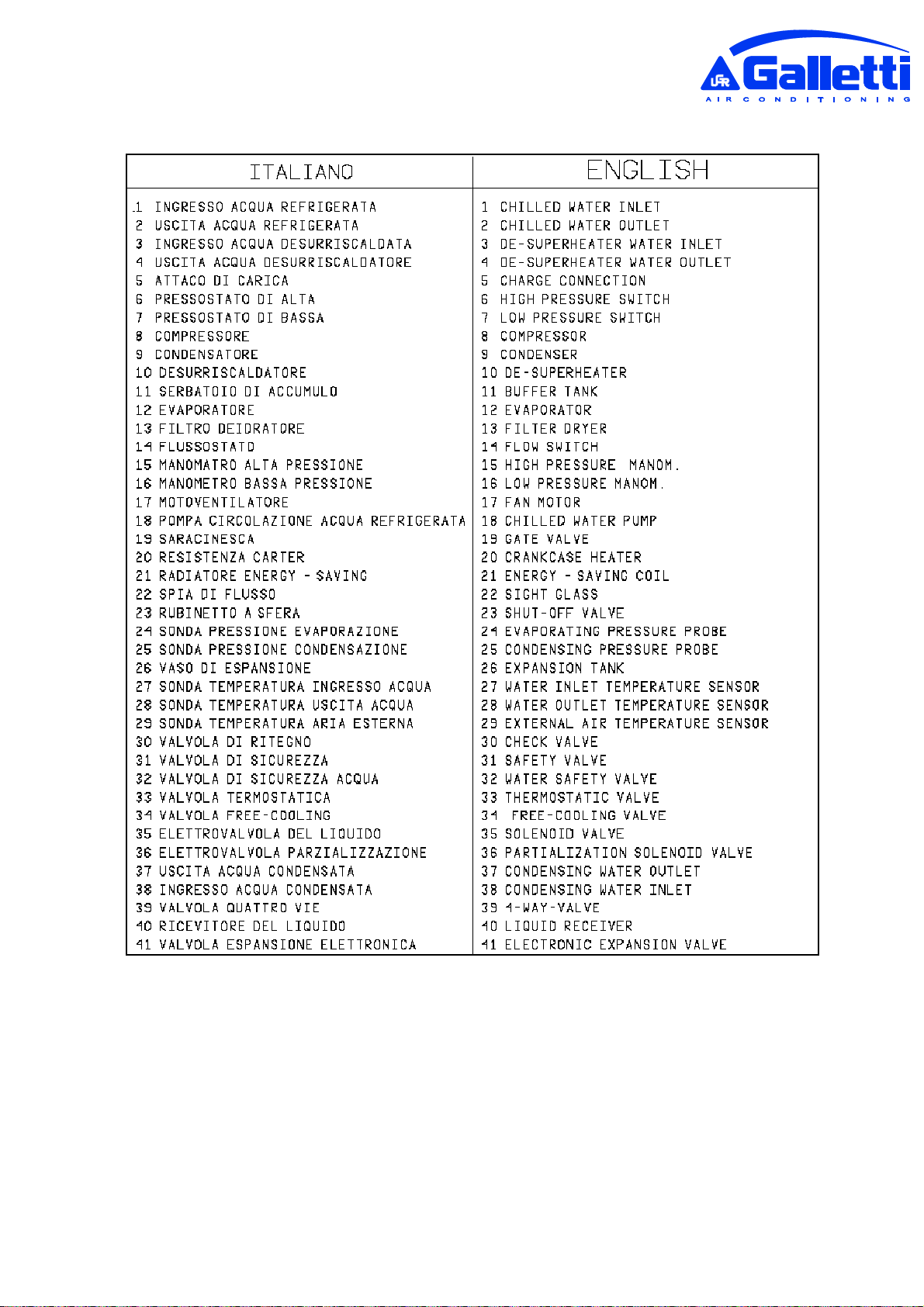

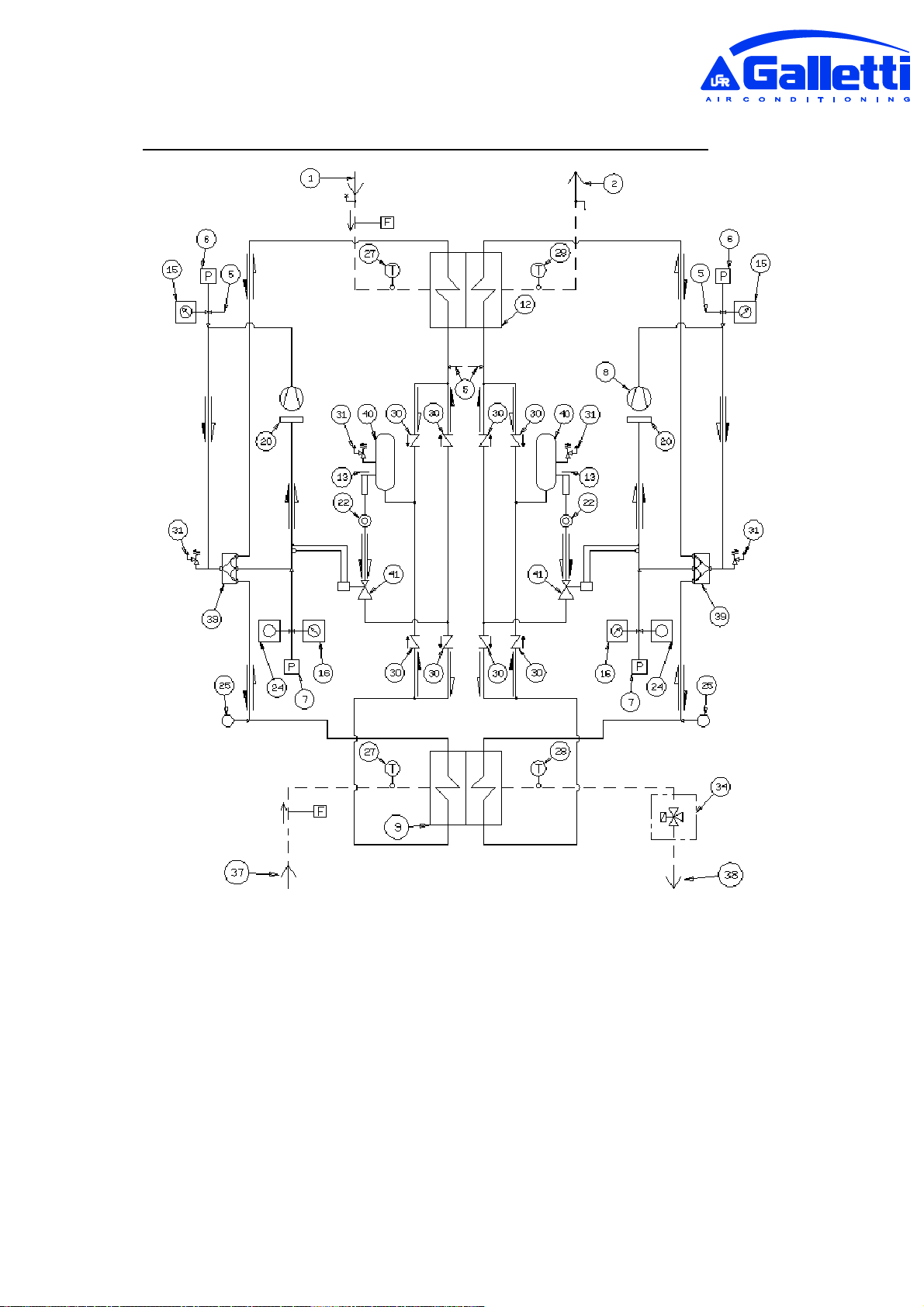

Chiller components:

oMolecular and alumina sieve filter dryer activated

oSight glass with humidity indicator. The key is directly on the sight glass.

oMechanical thermostatic valve + external equalisation and built-in MOP function

oElectric thermostatic valve with step motor and specific electronic driver for the

maximum efficiency of the cooling circuit and to optimise operating parameters.

oCycle inversion valve (only heat pumps)

oOne-way valves (only heat pump)

oHigh and low pressure switches

oSchrader valves for control, access and/or maintenance

oRefrigerant-side safety valve

Electrical control board: the electrical control board is implemented and wired in compliance

with the directives EEC 73/23 and EEC 89/336 and to related standards. The board can be

accessed through the small door after having activated the main switch. All the remote

controls are implemented with signals at 24 V, powered by an isolation transformer positioned

inside the control board. A T control kit composed of thermostat and auxiliary fan is available

on demand. The unit is rated IP 43. N.B.: the mechanical safety devices such as the high

pressure switch have characteristic direct intervention and any microprocessor control circuit

failure cannot affect its efficiency in compliance with 97/23 PED.

Control microprocessor: the microprocessor on-board the unit controls the various operating

parameters by means of a keyboard set-up on the electrical control board:

oCompressor connection/disconnection to maintain the set-point of the chiller inlet

water T;

oAlarm management

High/ low pressure

Antifreeze

Flow switch

Pump alarm

oAlarm signals

oDisplay of operation parameters

oAntifreeze protection of evaporator

oControl of maximum number of compressor starts

oSerial output control (optional) RS232, RS485

oIncorrect sequence phases [not viewed on µP, but keeps compressor from starting]

[ref. Microprocessor control manual for further details]