Page 4 - GVO1508

Well done you have finished the panels….

Points to note as you construct your shed:

Do not attempt to assemble panels in windy conditions

Make sure your foundations are squared and level before erecting panels.

It is easier to remove all swarf (filings) before you stand your walls up

Complete all panels before erecting your shed.

Keep a firm grip on panels when handling. If they slip they will cause damage.

Always wear non slip gloves protective footwear and eyewear.

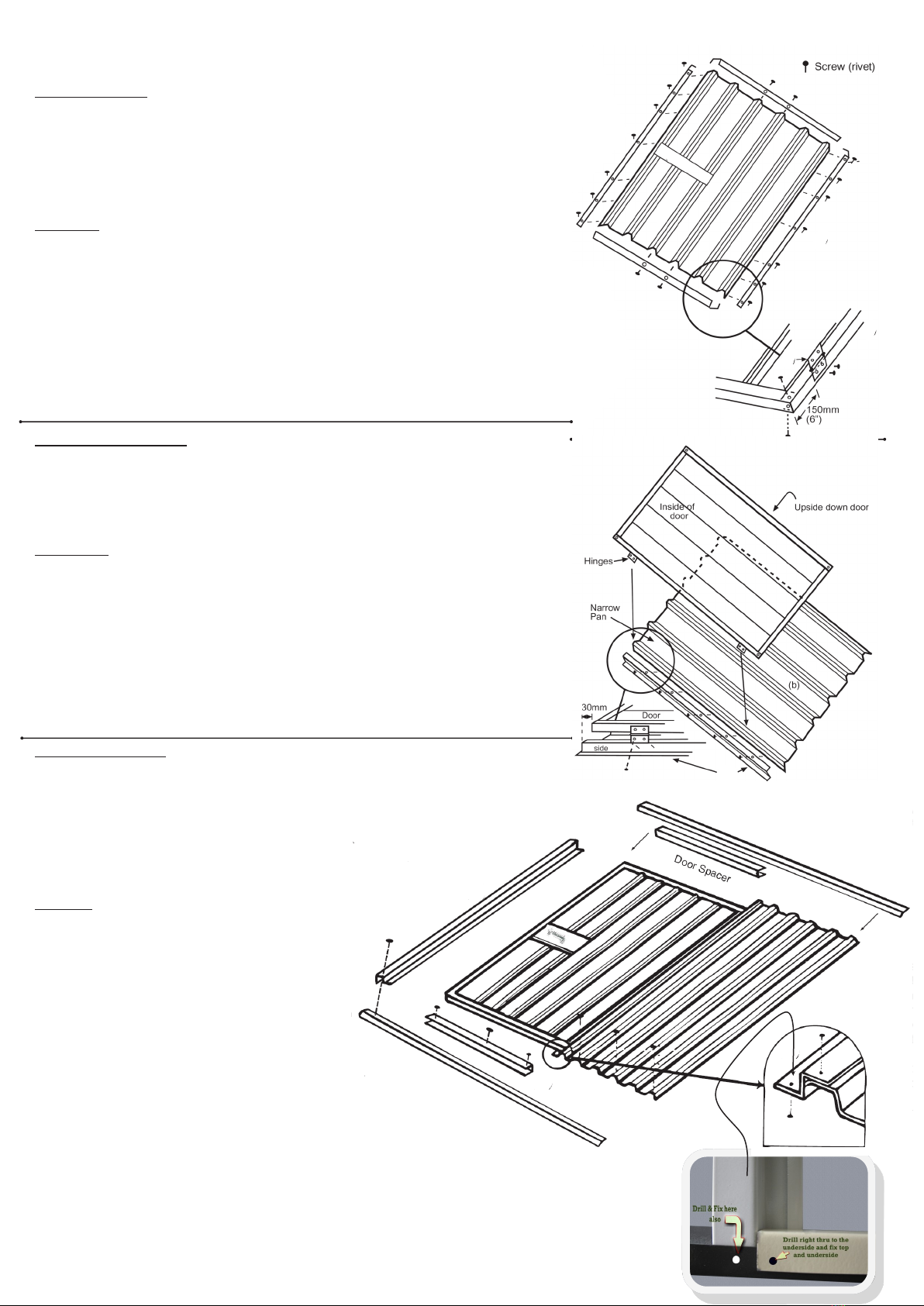

5: Now to join your corners and put your roof on….

1st: Stand up the back wall and as your helping hand is holding it up bring the one end wall into meet it at

the left corner overlapping the corners as Fig 1. Drill & Fix at approx 100mm down from

the top and up from the bottom drilling and fixing from the outside.

2nd: Bring the other end wall into the right back corner and perform the same again checking

to make sure the walls are sitting flat at the bottom

3rd: Bring the front wall into place and join the front corners to the end walls same as the

back.

4th: Finish joining corners by fixing at approx 300mm apart. You will find it easier to drill these corners if

they are supported on the inside. Use the handle end of a hammer into the inside of the

corner, but beware of drilling holes in the end of your hammer.

5th: With a person at each end of the roof, waft it over top of your upright walls and lower

down on top with an overhang that looks best to you. At the left end fix thru the “L”

flashing into the top channel of the left end wall. Measure the overhang at the back and fix

the right end “L” to the right end wall with the same overhang as the Left end. If the roof is difficult to

get to the same overhang at each end this will be caused by unlevel site or walls are not

square. Adjust accordingly. Fix “L”s at 300mm’s apart.

6th: Using your ladder and tape measure, fix down thru the top of the roof, thru the pan into

the top channel of front and back walls. (10mm more than the overhang). Fix beside every

2nd rib. (Fig 2). You will not need to worry about these fixings leaking as any water seep-

ing thru these fixings will end up on the outside of the walls.

7th: Attach padbolt to door strap if not already done so. Check that all swarf is removed and

most importantly….

8th: Fix your shed down to its foundations. If your foundations are unlevel or bowed, you will

have problems with your padbolt and door levels. This can be fixed by slipping a spade un-

der either door jamb and lifting. You will soon get a feel for which side needs propping up.

Well done!

If you choose to vary from these instructions your warranty will be impaired.

Recessed floor clamps

For especially poured floors

with recess around perimeter.

Flat floor clamps

For existing concrete only.

Water can seep underneath.

Fig 1

Fig 3

It is utmost essential that every shed has

a floor, but the only way to make sure

your shed is there to stay on windy sites is

with a recessed concrete floor and phone

0800 80 SHED for more free advise.

1. The door braces can be fitted now that you have assembled your shed.

2. Tuck one end of the 'Z' between the bottom channel of the inside of the door and

the sheet. Do the same at the top, overlapping in the centre behind the padbolt. If you

have a locking 'T' handle you will have to run the 'Z's the opposite way to the dia-

gram.

3. Rivet the 'Z's at the ends, and in the centre of the channel it is tucked under, and

through the overlap in the centre. Two or three more rivets will be required through

the door sheeting into the 'Z', but they will need to be riveted through from the outside

of the door for a neater appearance.

4. You may need to cut or bend the flange at the bottom and the top of the 'Z' if it

catches on the door jamb when opening or closing (diagram 1).

Page 1 - GVO1508

1.53m L x 0.78m W x 1.83m High

Flat Roof GARDEN SHED

Parts list

The following parts are included in your shed:

a. 4 x 1830 x 780mm sheets (Back wall and side walls)

b. 1 x narrow 1830 x 715mm sheet (beside door - Front)

c. 1 x 1770 x 780mm sheet (Door sheet)

d. 2 x 980 x 780mm sheets (Roof)

e. 6 x “U” channels 1515mm long, (Front & Back and Roof)

f. 4 x “U” channels 735mm long (Side walls)

g. 2 x “U” channels 1770mm (Door sides)

h. 2 x “U” channels 793mm (Door spacers)

i. 2 x “U” channels 780mm (door tops & bottoms)

j. 2 x 980mm “L” flashings (roof to side flashings)

k. 2 x 1830mm “Z” shaped door jambs, 1 has “U” channel attached to give this

shape for corner door jamb. (Front)

l. 1 x GALVO Door strap - 310mm long

m.1 pack screws and padbolt &

n. 1 pack of Rivets and hinges.

Caution: Some parts have sharp edges and should be handled very careful-

ly. We recommend the use of protective gloves and footwear when assembling.

All dimensions are approximate.

You will need these tools to assemble your shed:

Battery or electric Drill

3.3mm (1/8th inch) Drill bit

Screwdriver & Riveter

Tape measure & Ladder

Feel free to phone 0800 454 873 for an installer near you...

Do not attempt to erect shed in windy weather.

External Dimensions: 1530mm x 780mm

Internal Dimensions: 1485mm x 735mm

If you feel a little anxious about

erecting your shed. Please phone

0800 ENZEMBLE (369 362) for full

assembly service.

GVO1508