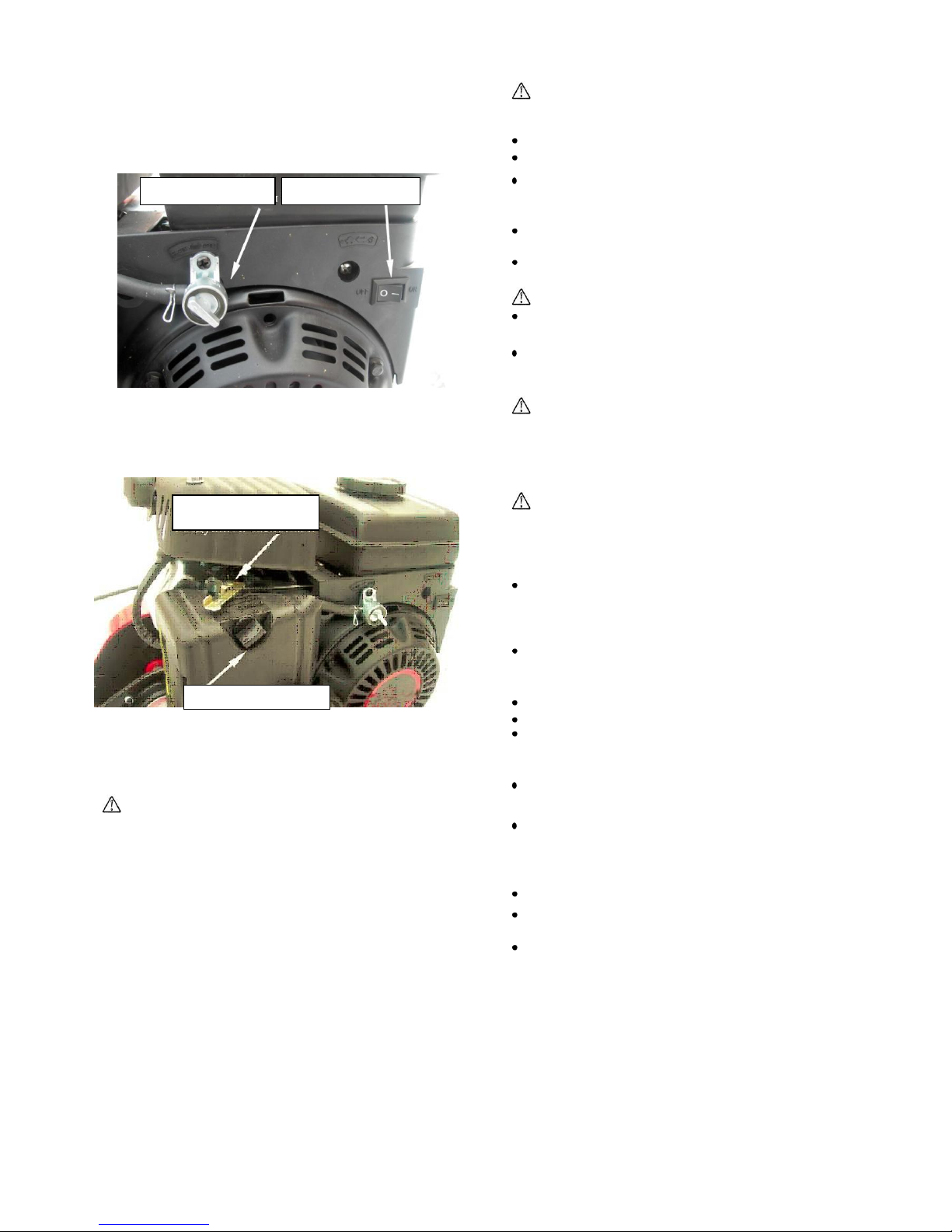

Figure

13 Figure 14

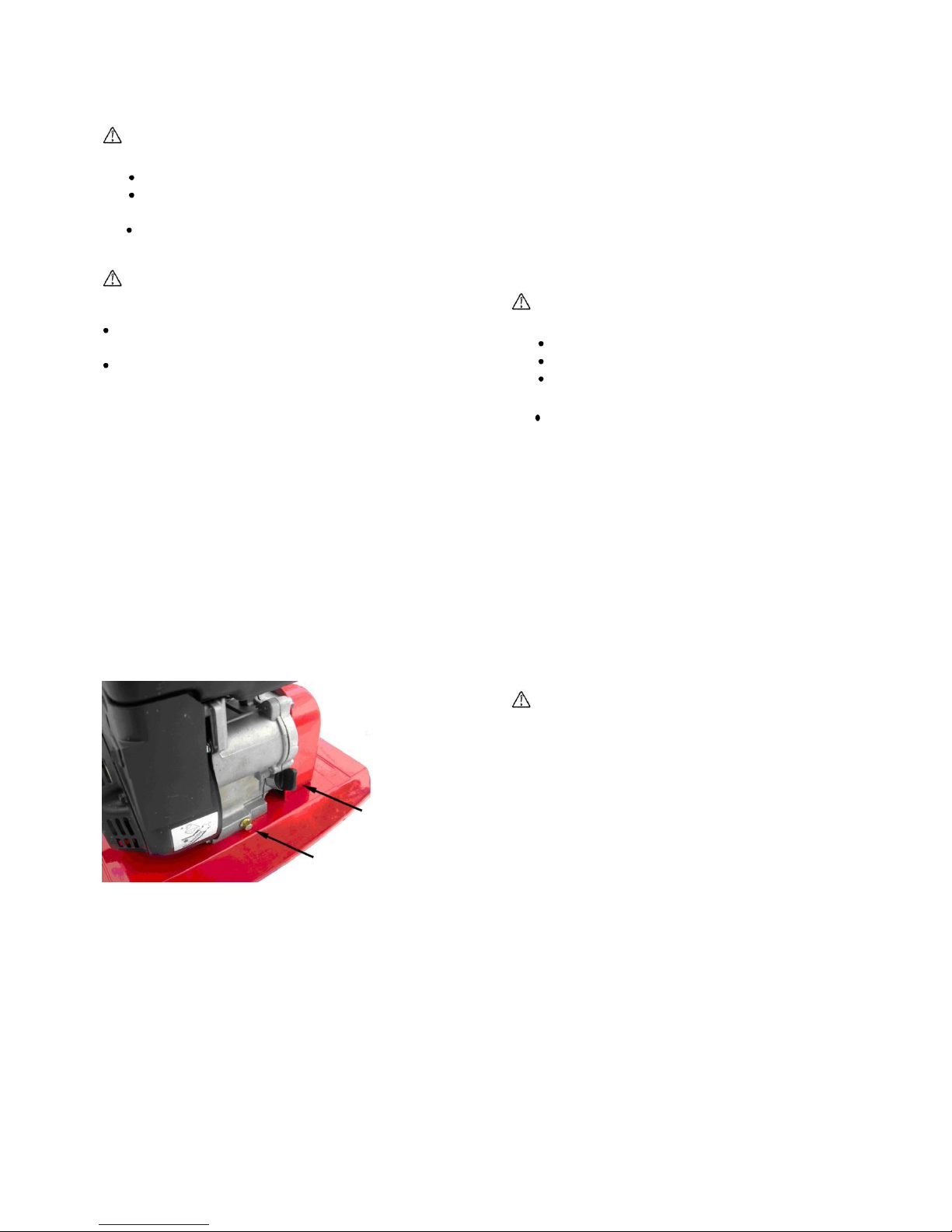

2. Filling up the fuel tank with petrol

Filling-up of fuel tank with petrol is done prior to starting the

engine. Do not open the fuel tank cover if the engine is hot or

operating.

Screw on the fastening nut and check the clutch cable

again for proper tensioning.

Operation

Prior to the first use

Warning

CHECK THE TIGHTNESS OF ALL THREADED

CONNECTIONS ON THE CULTIVATOR, INCLUDING THE

FIXATION OF THE ENGINE.

1. Filling up the engine case with oil

Warning

THE CULTIVATOR ENGINE CASE IS DELIVERED

WITHOUT OIL!

Prior to the first start of the engine, fill up the case with oil of

proper amount that is 0.4 litres.

The oil level should reach the lower level in the oil filling

outlet when standing straight (see: Figure 14).

Choose the oil viscosity in accordance with the ambient

temperature, using the diagram below:

The following codes must be found on the oil can: API "SF” or

“SG”, “SH”, “SJ”, “SL”, “SM”.

Under normal operating conditions and in normal temperature

ranges, we recommend the following oil viscosity: SAE 10W-

30.

Note: The oil level check is done with cold engine not

operating. Place the cultivator on a straight, horizontal

surface, supported on the blades and the wheels.

1. Screw off the oil filler cover (see: Figure 14).

2. Check the oil level and fill it up if necessary.

3. Place back and screw in the oil filler cover.

Order of checking the oil level:

Warning

The oil level must reach the lower level in the in the oil filling

outlet.

Prior to filling up with petrol, place the cultivator in a place

where it is not subjected to the action of fire or spark.

Safety engineering rules during operations with

petrol

Danger

Petrol and its vapour may easily flame up and explode!

Prior to filling up, stop the engine and wait until it cools

down entirely.

Wipe through all parts of the cultivator on which petrol

dropped during the filling-up.

Start the engine far away from the place where the filling-

up was made and where the petrol flew out on the earth.

Prior to starting the engine, make sure that the fuel tank is

properly fastened and its cover is screwed tight.

Storethe petrol only in special, clean and closablecans.

Do not let petrol get on your skin and do not inhale its

vapours.

Danger! Petrol must be stored in a place

unreachable for children!

DO NOT SMOKE WHILE FILLING UP THE ENGINE

WITH FUEL.

For the prevention of fire, clean the cultivator components

including the engine surface, the exhaust silencer and

the fuel tank from grass. When filling up with petrol, use

a clean funnel.

The engine should be filled up with clean, fresh, non

ethylated, lead free petrol of octane number at least 95.

Fill up the petrol in such a way that its level does not

exceed 1 cm distance from the upper edge of the mesh

filter.

DO NOT USE CONTAMINATED PETROL OR PETROL

MIXED WITH OIL.

Note: In order to avoid unstable operation of the engine,

always fill up the petrol in due time.

Engine start-up

Danger! Carbon monoxide poisoning will occur if you

inhale the exhaust gases.

DO NOT start the engine in closed premises.

Prior to the engine start-up:

Check whether there is petrol in the fuel tank, and

check the oil level in the engine case.

Make sure whether the clutch lever is pressed on

(whether it is blocked in pressed-on condition).