STRONG. SIMPLE. COMPACT.

Rev Date 23 0610

EDGE INSTALLATION MANUAL PAGE 4

Mounting the EDGE Fixtures

• EDGE series wet location xtures are typically surface mounted (Walls, Softs, etc.). If mounting to the

building softs, it is recommended to mount the xtures on the outer edges of the softs to maximize

the distance from the building walls. Fixtures should be aimed downward and slightly inward toward the

building for the best effect.

• Each xture has an input (male) and output (female) end. The end of the xture with the product

identication label is the input end. The xture must be installed with the input end oriented in the

direction of your incoming power source or leader cable.

• The location of the xtures must follow your site-specic layout.

• For long linear runs, G&G recommends using a chalk line or laser to mark the mounting bracket locations.

• 2’, 4’, and 6’ xtures require at least two mounting brackets. Brackets should be installed near the ends of

the xtures. 8’ models require three brackets with the third bracket being installed near the center of the

light xture.

• This product makes use of a push-click connector system. An audible click upon insertion of the connector

indicates that the connector is fully seated. Failure to fully seat connectors can lead to cable and xture

damage during use.

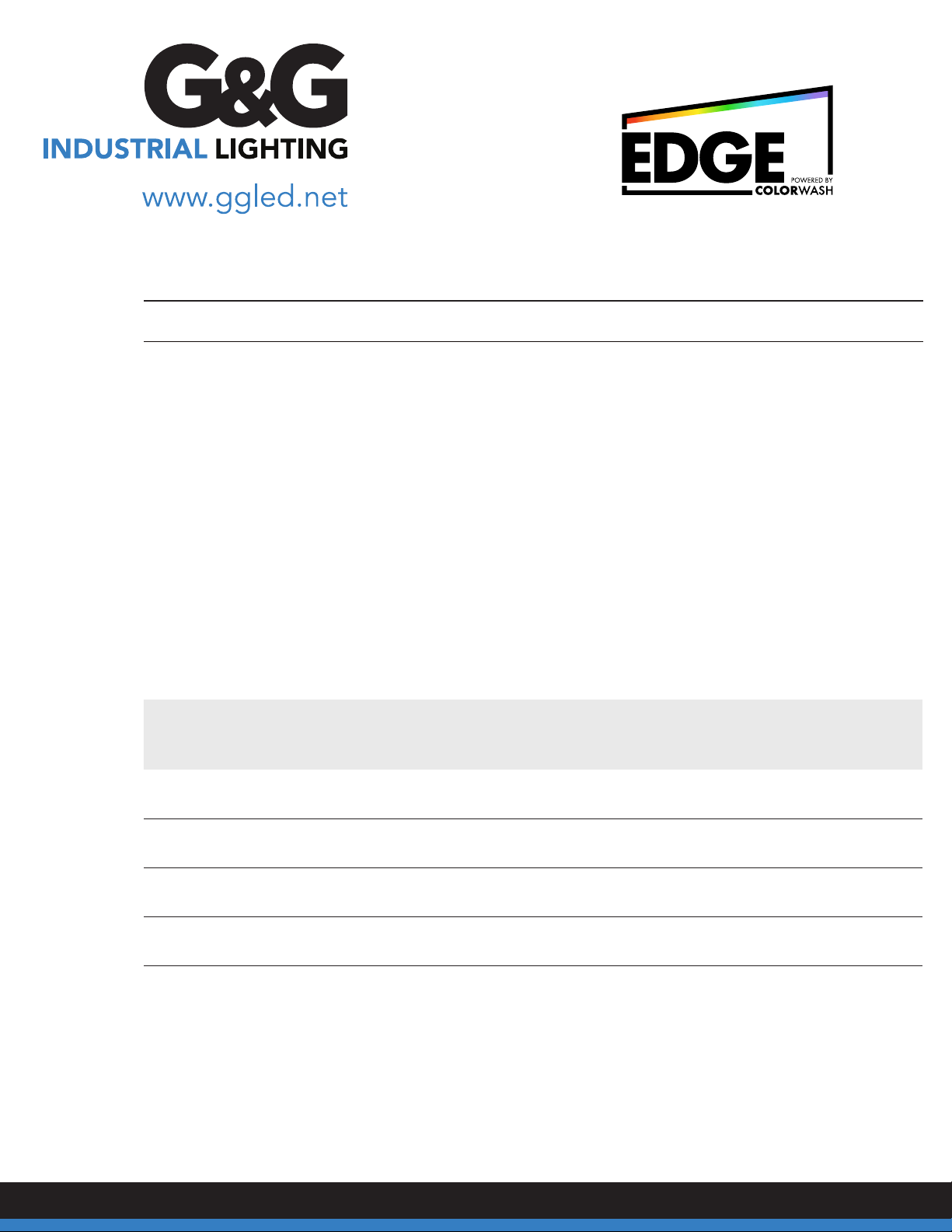

Connect the power leader cable to

the input connector (male) on the LED

xture. To do this, align the connectors,

push inward, and listen for the audible

click sound that indicates that the

connector is fully seated.

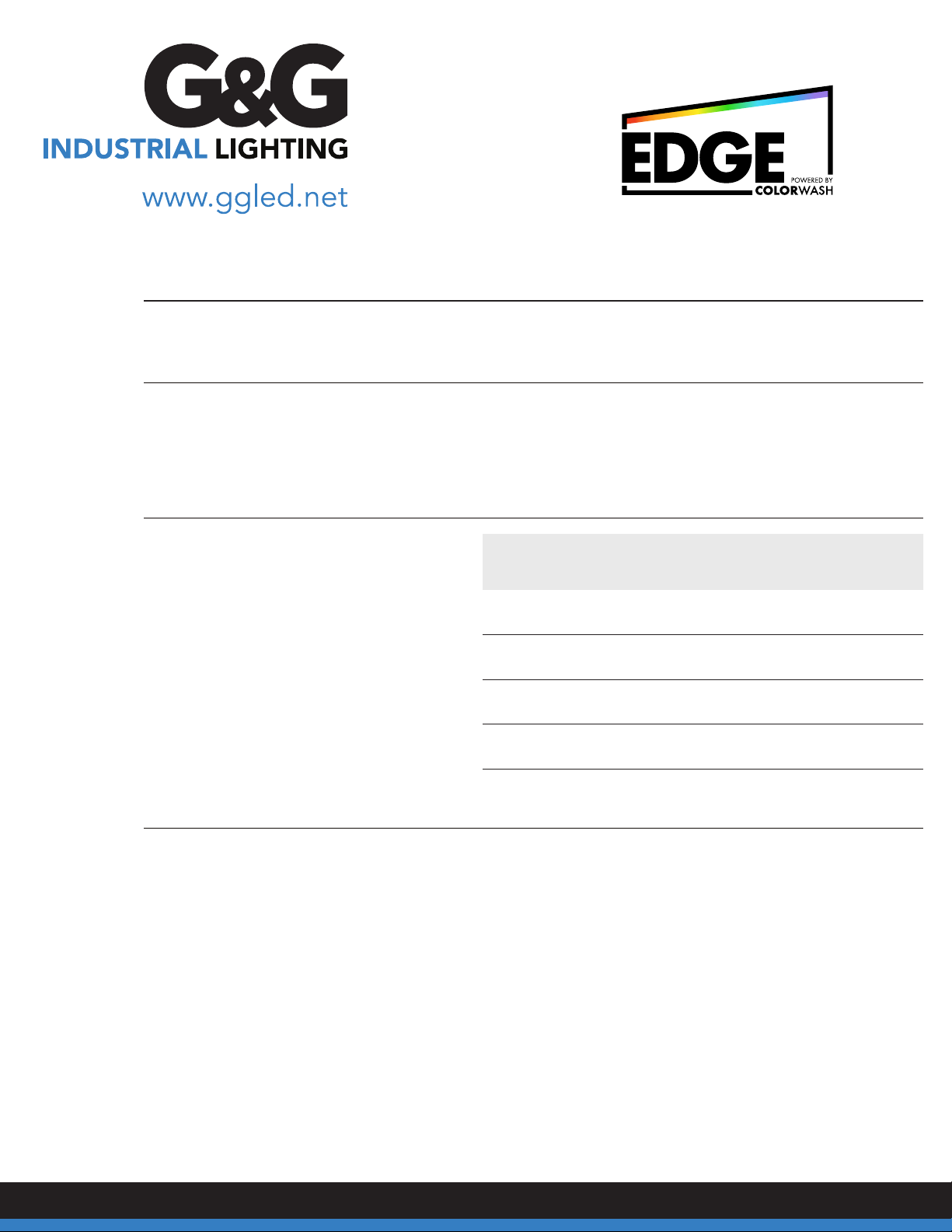

When daisy chaining xtures continue mounting xtures and

attach jumper cables as needed using the same push-click

connection method as the leader cable.

Mount the xture(s) in their specic location using the Surface Mount Bracket to afx directly to the ceiling or softs.