1 Introduction......................................................................4

1.1 About this manual............................................................. 4

1.2 Disclaimer............................................................................... 4

1.3 Warranty and complaints............................................ 4

1.4 Contact information........................................................ 4

2 Safety ..................................................................................5

2.1 Denition of safety levels............................................ 5

2.2 Signs on the lifting yoke.............................................. 5

2.3 General.....................................................................................6

2.4 Incorrect handling............................................................ 7

2.4.2 Lifting with one hook................................................. 7

2.4.1 Load imbalance.............................................................. 7

2.4.3 Impact................................................................................... 7

2.4.4 Centring ..............................................................................8

2.4.6 Relieving the load from the lifting yoke......8

2.4.5 Long load ..........................................................................8

2.5 Safety during operation...............................................9

3 Description .................................................................... 10

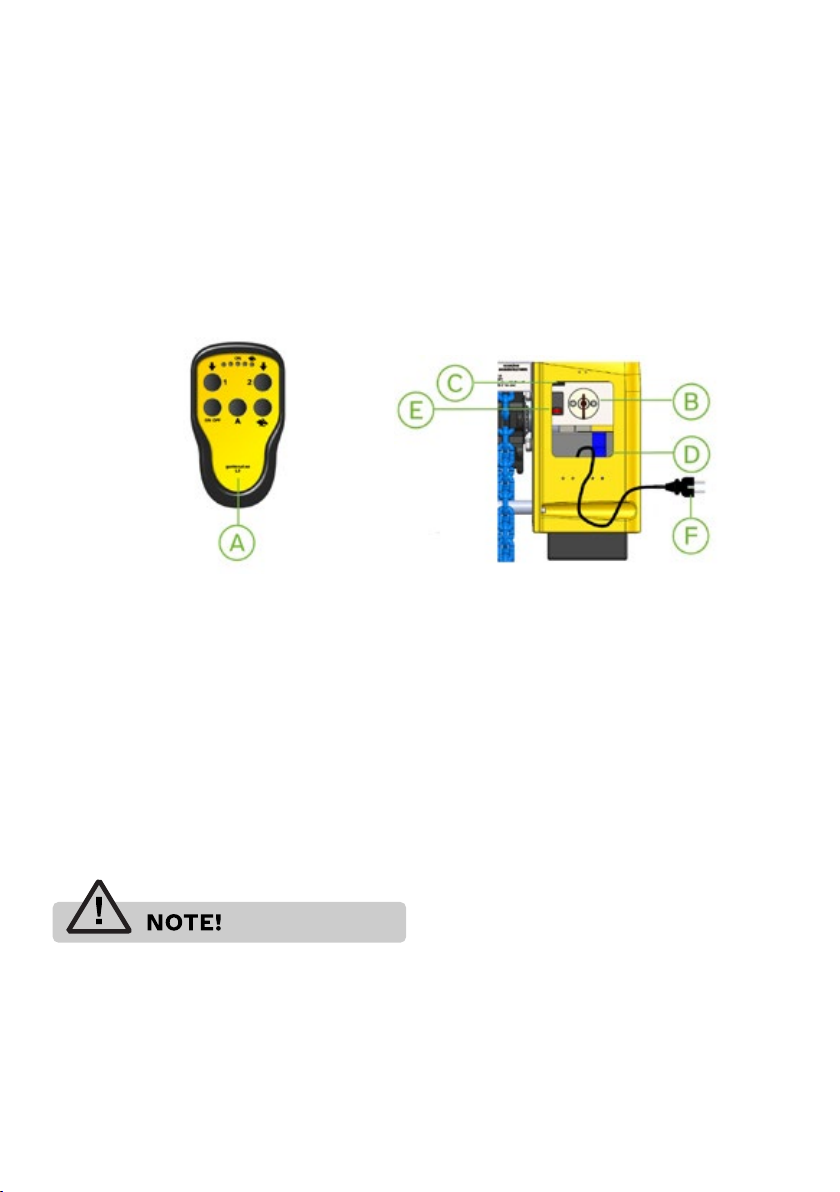

3.1 Overview................................................................................10

3.2 Lifting capacity ................................................................10

3.2.1 Lifting table.......................................................................11

3.2.2 Levelling expressed as height dierence

12

3.3 Remote control. ...............................................................13

3.4 Intended use......................................................................13

3.5 Disposal.................................................................................13

Contents

4 Operation.........................................................................14

4.1 Daily inspection................................................................14

4.1.1 Before use.........................................................................14

4.1.2 After use.............................................................................14

4.2 Operating the lifting yoke.........................................15

4.2.1 Preparations....................................................................15

4.3 Calibration of the neutral position......................16

4.5 Synchronising new remote control with

lifting yoke....................................................................................17

5 Tandem operation...................................................... 18

6 Maintenance.................................................................20

6.1 Charging the batteries in the lifting yoke ....20

6.2 Replacing batteries in the remote control.20

6.4 Storage and transport.................................................21

6.5 Cleaning................................................................................21

6.6 Inspection............................................................................21

7 Technical data ............................................................. 22