General installation checklist

1) Place the softener where you want to install the unit. NOTE: Be sure the softener is level and on a firm base.

2) During cold weather it is recommended that the installer warm the valve to room temperature before operating.

3) Perform all plumbing according to local plumbing codes. Use a 1/2" minimum pipe size for the drain.

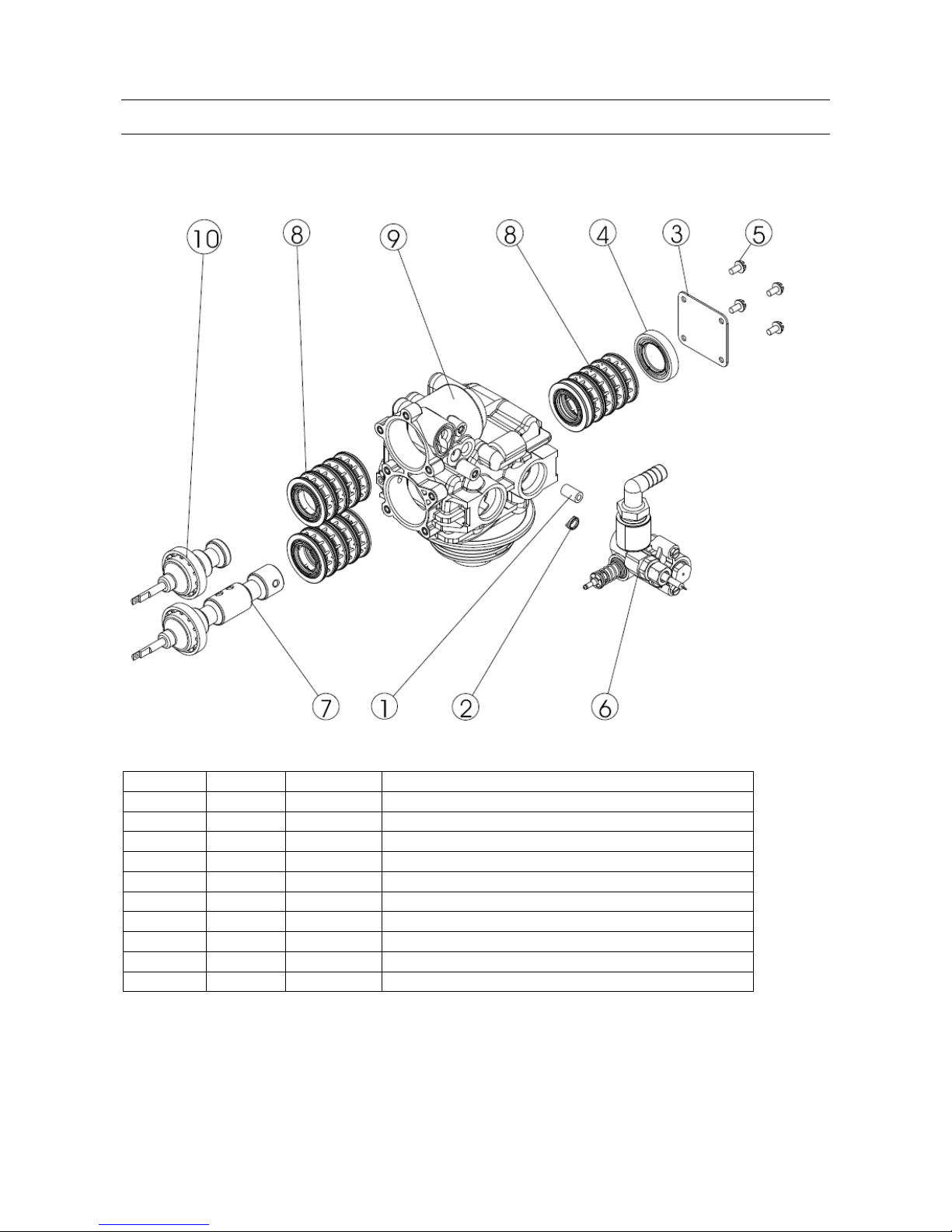

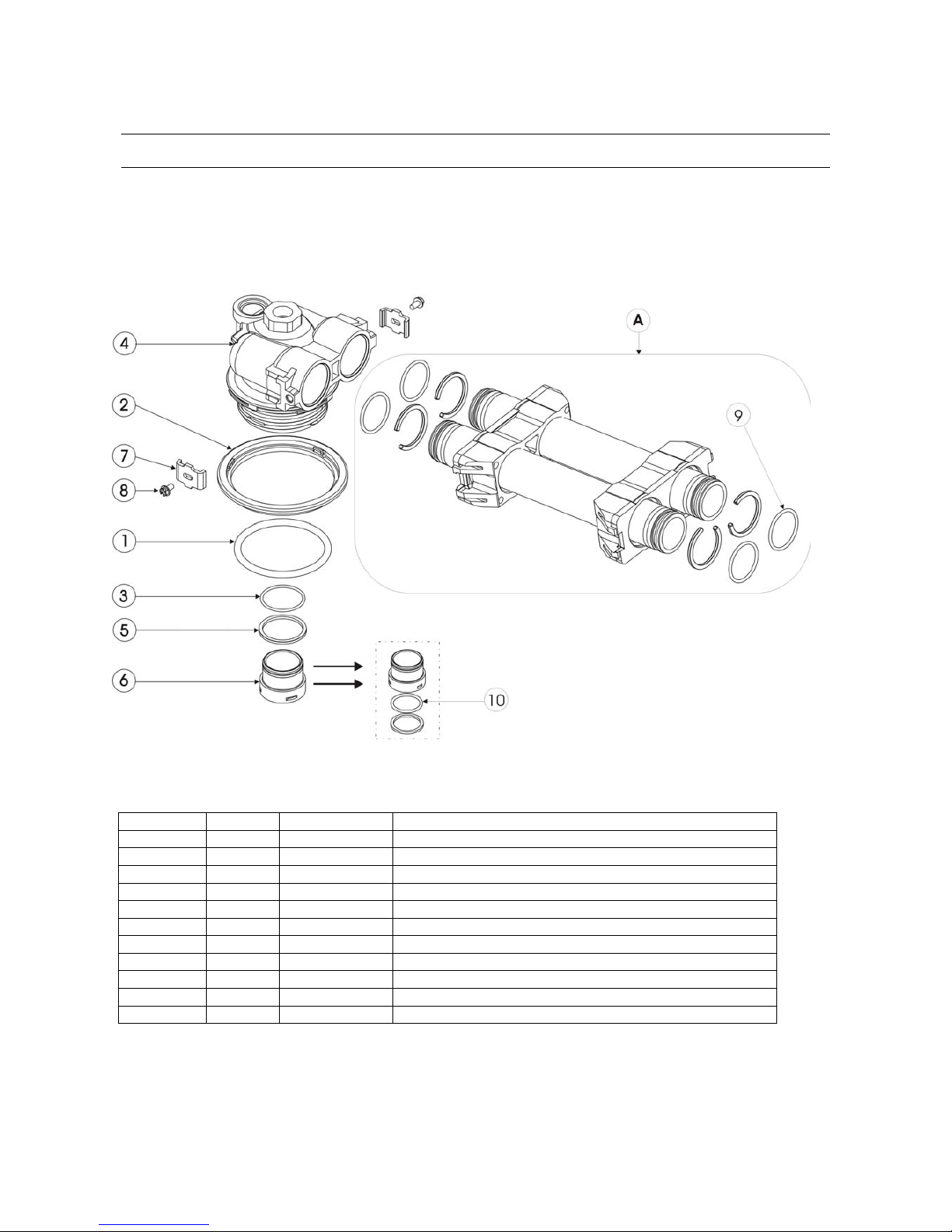

4) The 1" distributor tube must be flush with the top of each tank. Cut if necessary. Chamfer the end slightly in order to

avoid the deterioration of the o-ring seal at the time of the assembly

5) Use only non-aerosol 100% silicone lubricant for the distributor tube o-ring. Do not use any other type of grease or

lubricant as they will cause damage to the valve.

6) The Solder joints to the principal plumbing and the drain must be carried out before the softener is connected. Failure

to do so could cause irreversible damage to the softener

7) Use only ribbon Teflon ® to make any threaded connections.

8) Ensure that the ground under the softener is quite clean and to plan.

9). Fill the softener cabinet with approx. 2” (50mm) water. Do not add salt to the brine tank at this time.

10) Put the by-pass valve of the softener into the "by-pass" position. Turn on the main water supply. Open a cold soft

water tap nearby and let water run a few minutes or until the system is free of foreign material (usually solder) resulting

from the installation. Close the water tap when water runs clean.

11) Place the bypass into the "Service" position and let water flow into the mineral tank. When water flow stops,

slowly open a cold water tap nearby and let water run until the air is purged from the softener. Then close tap.

12) When the softener is connected electrically, the valve may cycle itself and change over the position service.

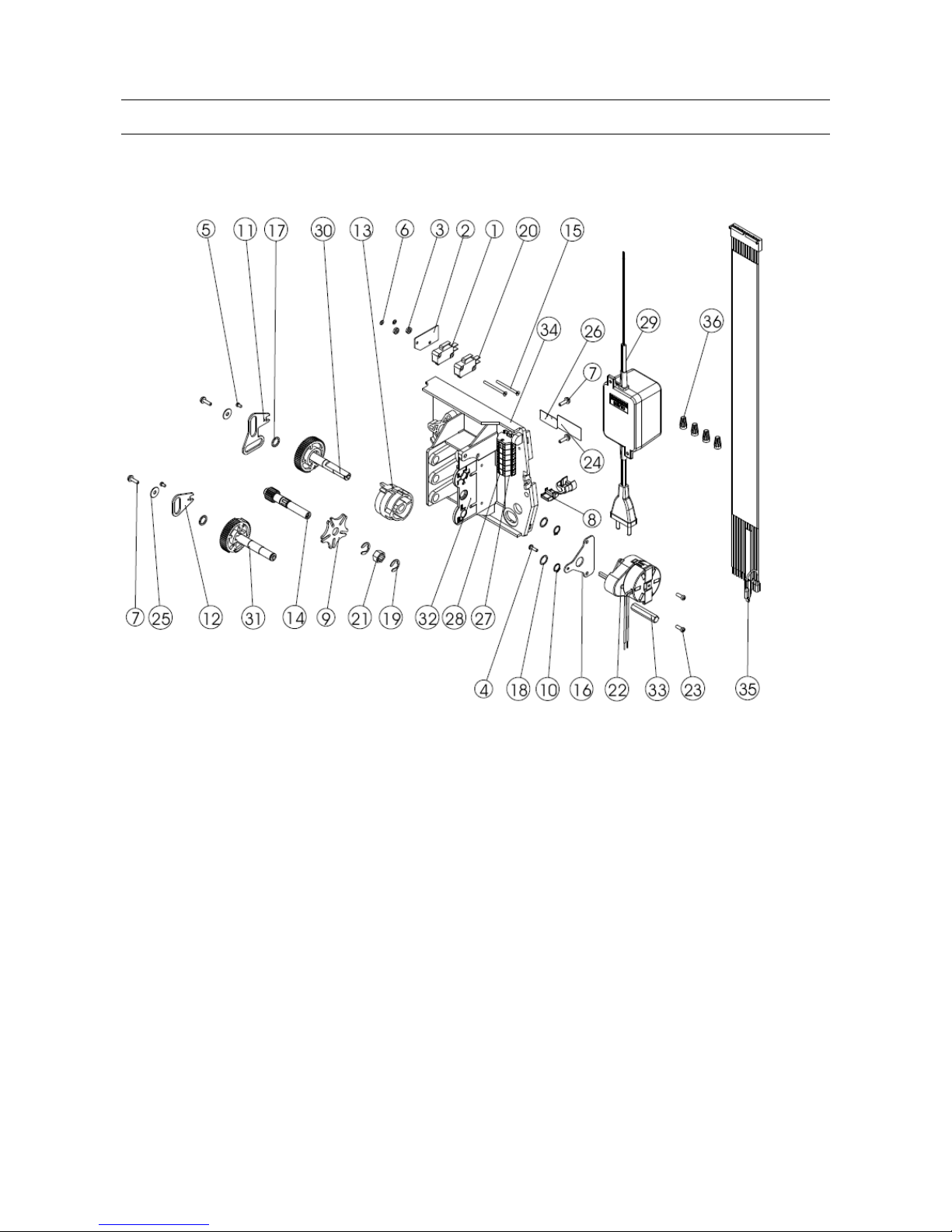

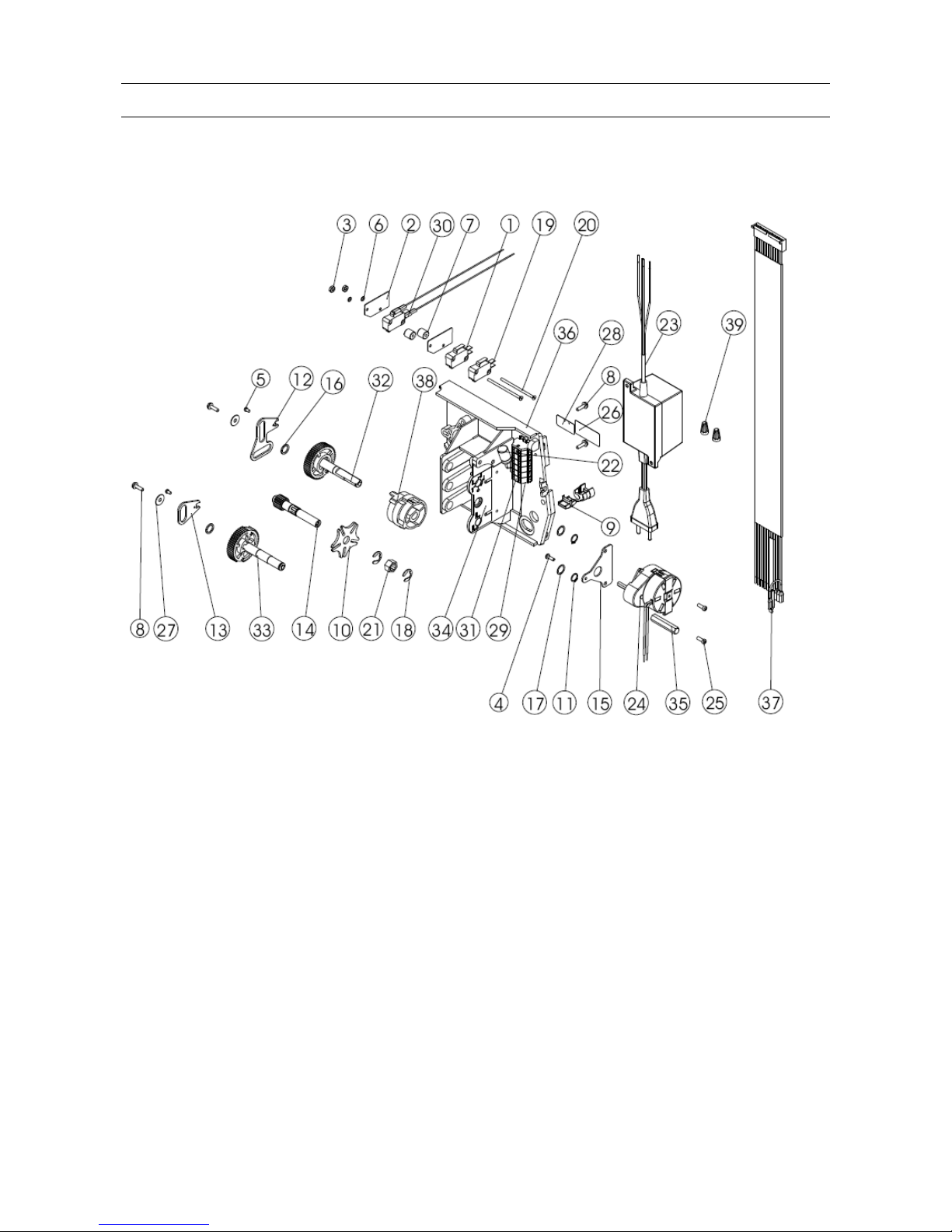

13) The valve includes an indicator to inform the fitter of its position: the wheel directly below the motor indicates the

tank that is currently in the service position. The Digital display on the front of the softener alternates between the

volume remaining in the service tank, the number of the tank in service (U-1 or 2 corresponds with the wheel:

"INDICATION of the TANK IN SERVICE") and the time of the day.

Important: to understand various dislays please refer to the service manual Programming chapter.

14) Initiate a regeneration and bring the valve to cycle 1, by pressing the regeneration button. The valve begins by

transfering from one tank to the other and then entering the regeneration cycle of the tank that was in service. The water

runs until the system is purged of the air. Once the air is completely evacuated, it enters the Brine draw & slow rinse

stage and then into brine refil. On return to the service position repeat the precedure. This allows the complete purge of

the second bottle.