2

1. INTRODUCTION ...................................................................................................................................................................................................................................................... 3

2. ADVANCED FEATURES........................................................................................................................................................................................................................................ 3

3. IMPORTANT SAFETY INFORMATION............................................................................................................................................................................................................ 3

4. TOO S .......................................................................................................................................................................................................................................................................... 4

5. GARAGE .................................................................................................................................................................................................................................................................... 4

6. OPERATOR PACKAGE CONTENTS .................................................................................................................................................................................................................. 6

7. IMPORTANT INSTA ATION INSTRUCTIONS .......................................................................................................................................................................................... 7

8. INSTA ATION STEPS .......................................................................................................................................................................................................................................... 8

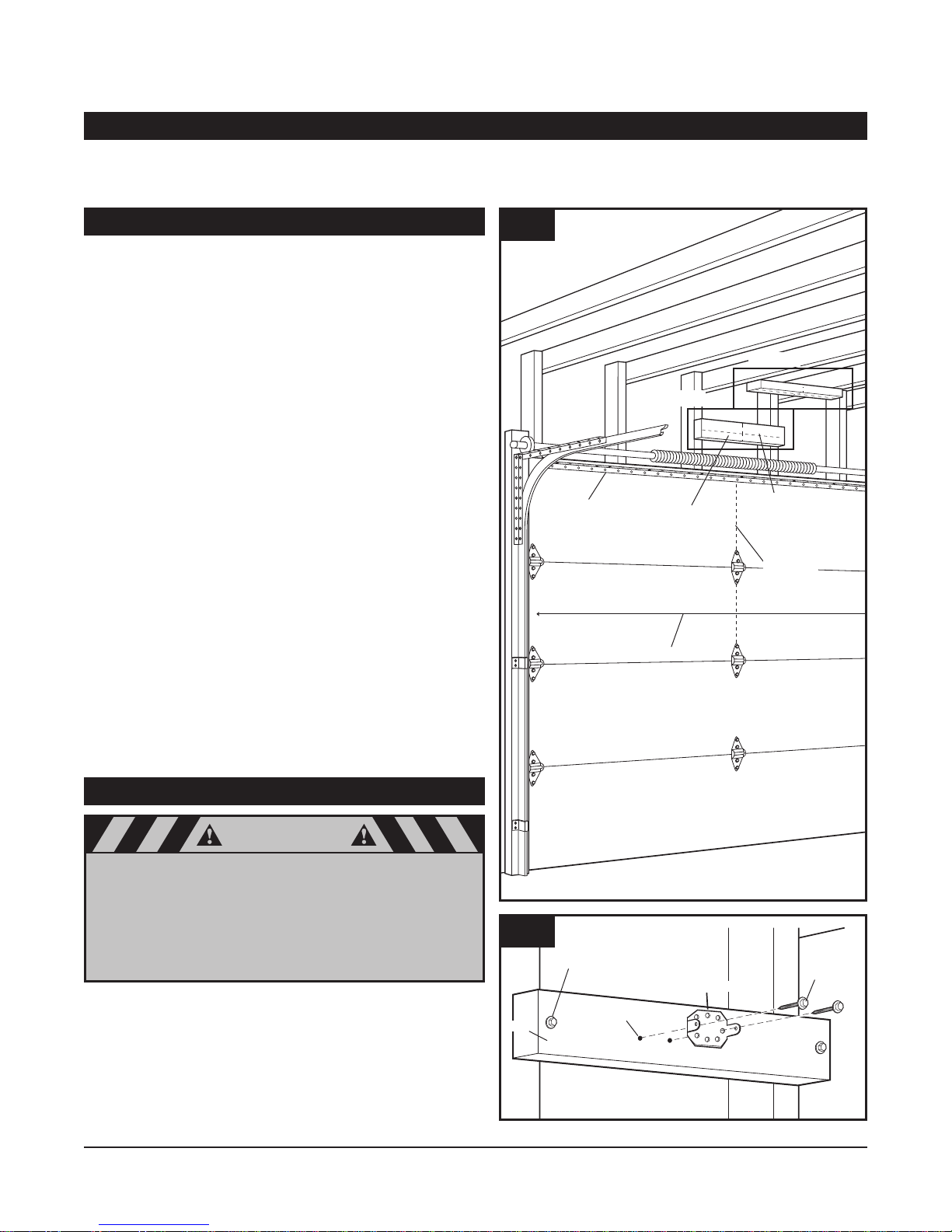

8.1 MEASURE AND MARK DOOR AREA .................................................................................................................................................................................. 8

8.2 INSTA HEADER BRACKET .................................................................................................................................................................................................... 8

8.3 INSTA DOOR BRACKET TO DOOR.................................................................................................................................................................................... 9

8.4 ATTACH RAI TO OPERATOR HEAD .................................................................................................................................................................................. 10

8.5 ATTACH RAI TO HEADER BRACKET ................................................................................................................................................................................ 11

8.6 POSITION OPERATOR FOR MOUNTING .......................................................................................................................................................................... 11

8.7 MOUNT OPERATOR TO CEI ING ........................................................................................................................................................................................ 12

8.8 CONNECT ARM TO DOOR AND TRO EY .................................................................................................................................................................... 12

8.9 CHECK EMERGENCY RE EASE .......................................................................................................................................................................................... 13

8.10 INSTA PHOTO EYE SAFETY SYSTEM ............................................................................................................................................................................ 14

8.11 INSTA WA CONTRO PANE ...................................................................................................................................................................................... 15

8.12 CONNECTING WIRES TO OPERATOR................................................................................................................................................................................ 15

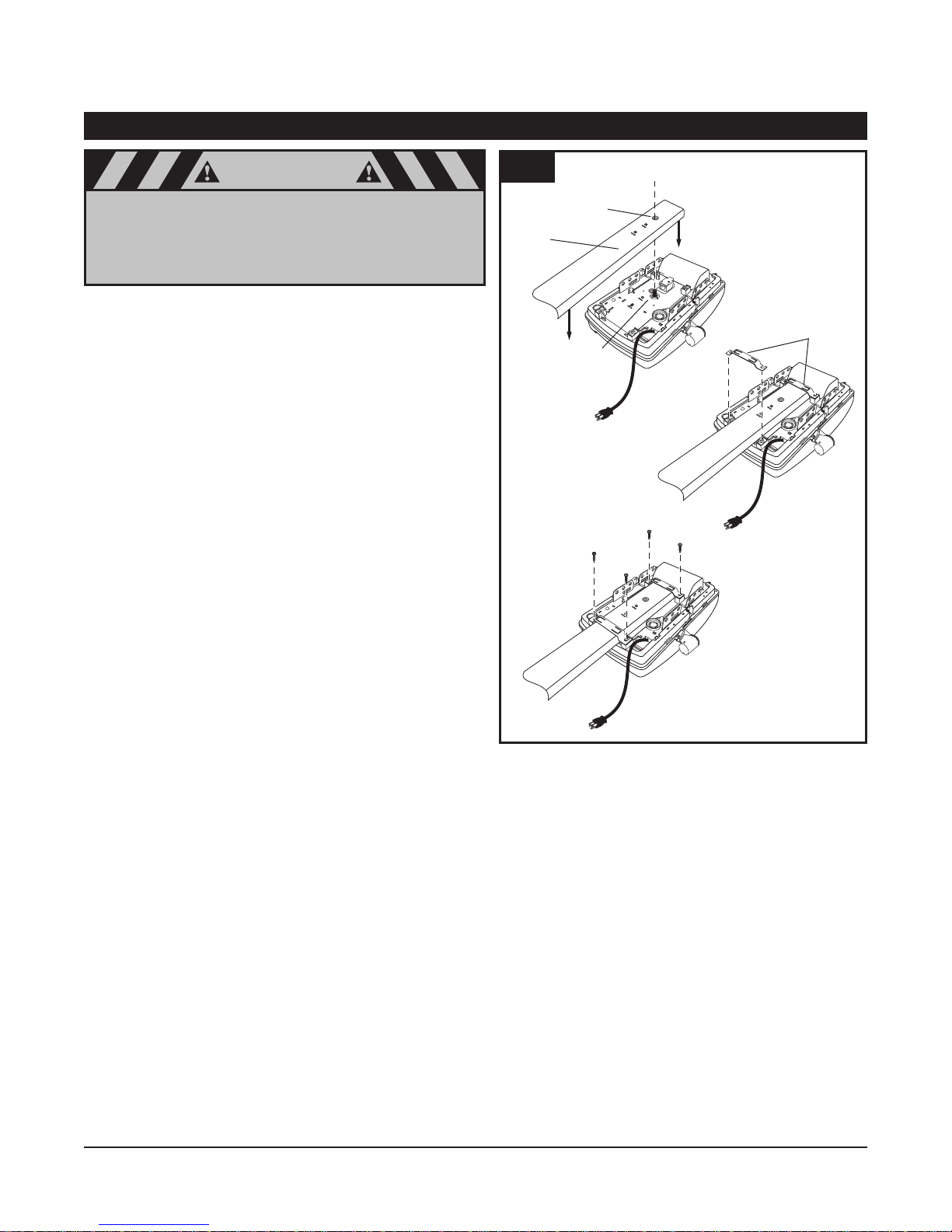

8.13 INSTA IGHT BU BS AND ENSES .............................................................................................................................................................................. 16

8.14 CONNECT TO POWER .............................................................................................................................................................................................................. 17

8.15 CONTRO PANE ...................................................................................................................................................................................................................... 18

8.16 INITIA SYSTEM SET UP.......................................................................................................................................................................................................... 18

8.17 ADVANCED SETTING................................................................................................................................................................................................................ 20

8.18 TEST SAFETY REVERSA ..........................................................................................................................................................................................................23

8.19 A IGN AND TEST PHOTO EYE SENSORS........................................................................................................................................................................ 24

8.20 APP Y ABE S TO INSIDE OF GARAGE .......................................................................................................................................................................... 25

8.21 ATTACH OWNER’S MANUA TO WA ............................................................................................................................................................................ 25

9. IMPORTANT SAFETY INSTRUCTIONS........................................................................................................................................................................................................ 25

10. TRANSMITTERS .................................................................................................................................................................................................................................................. 26

11. OPERATION OF YOUR OPERATOR .............................................................................................................................................................................................................. 27

12. HOME INK®TRANSCEIVER .......................................................................................................................................................................................................................... 27

13. MODU AR ANTENNA ...................................................................................................................................................................................................................................... 27

14. TENSION ADJUSTMENT .................................................................................................................................................................................................................................. 28

15. RAI ENGTH ADJUSTMENT - FOR PROFESSIONA INSTA ERS ON Y................................................................................................................................ 28

16. RAI ASSEMB Y PARTS .................................................................................................................................................................................................................................. 29

17. OPERATOR ASSEMB Y PARTS ...................................................................................................................................................................................................................... 30

18. ACCESSORIES ...................................................................................................................................................................................................................................................... 32

19. HAVING A PROB EM? ...................................................................................................................................................................................................................................... 33

20. TROUB ESHOOTING - FOR PROFESSIONA INSTA ERS ON Y................................................................................................................................................ 34

21. MAINTENANCE AND ADJUSTMENTS ...................................................................................................................................................................................................... 35

22. IMITED PARTS WARRANTY.......................................................................................................................................................................................................................... 35

23. WARRANTY IMITATIONS, C AIMS AND SERVICE............................................................................................................................................................................ 36

24. REGISTRATION .................................................................................................................................................................................................................................................... 36

OWNER’S MANUAL CONTENTS

Conversion :

1 foot = 33 cm

1 inch = 2.54 cm