Brush Cutter

GBC26C 6

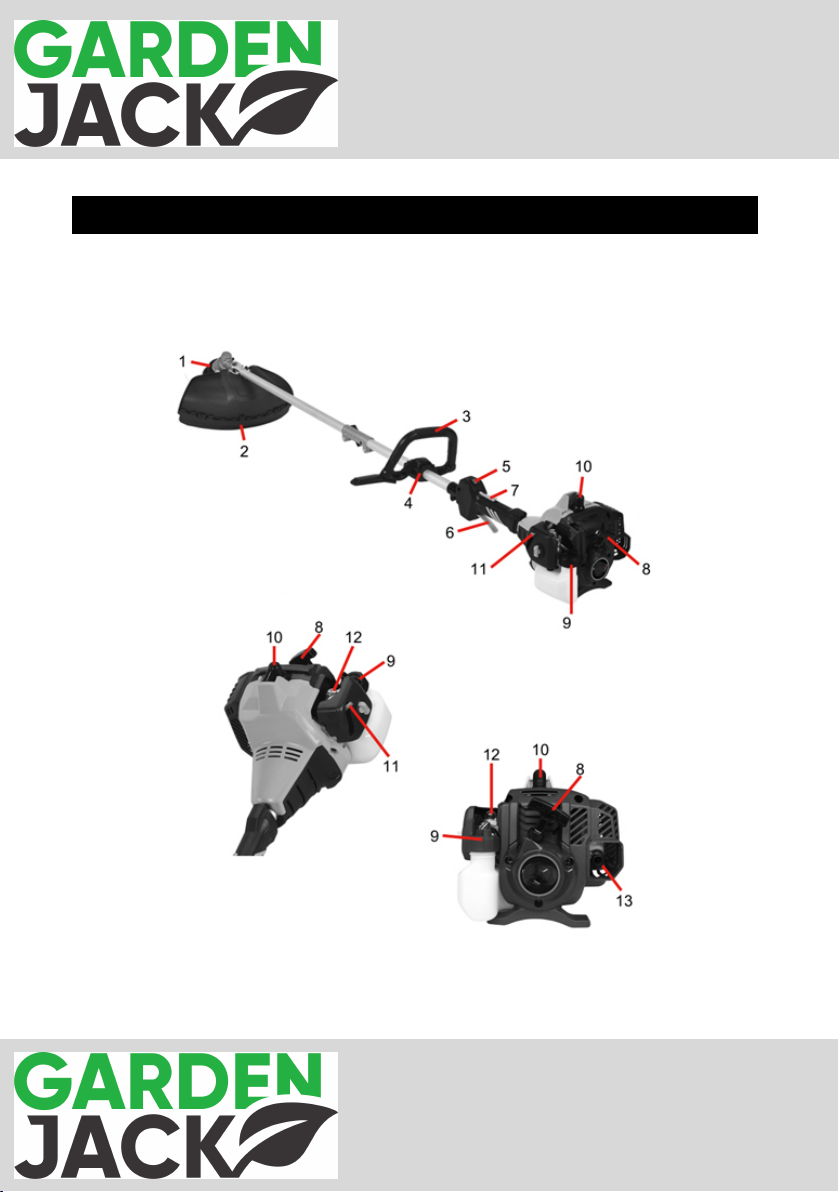

Mounting

5. Mount the protective hood (2) on

the provided holder, as shown in the

figure.

6. Use the included hex key to tighten

the hex screws.

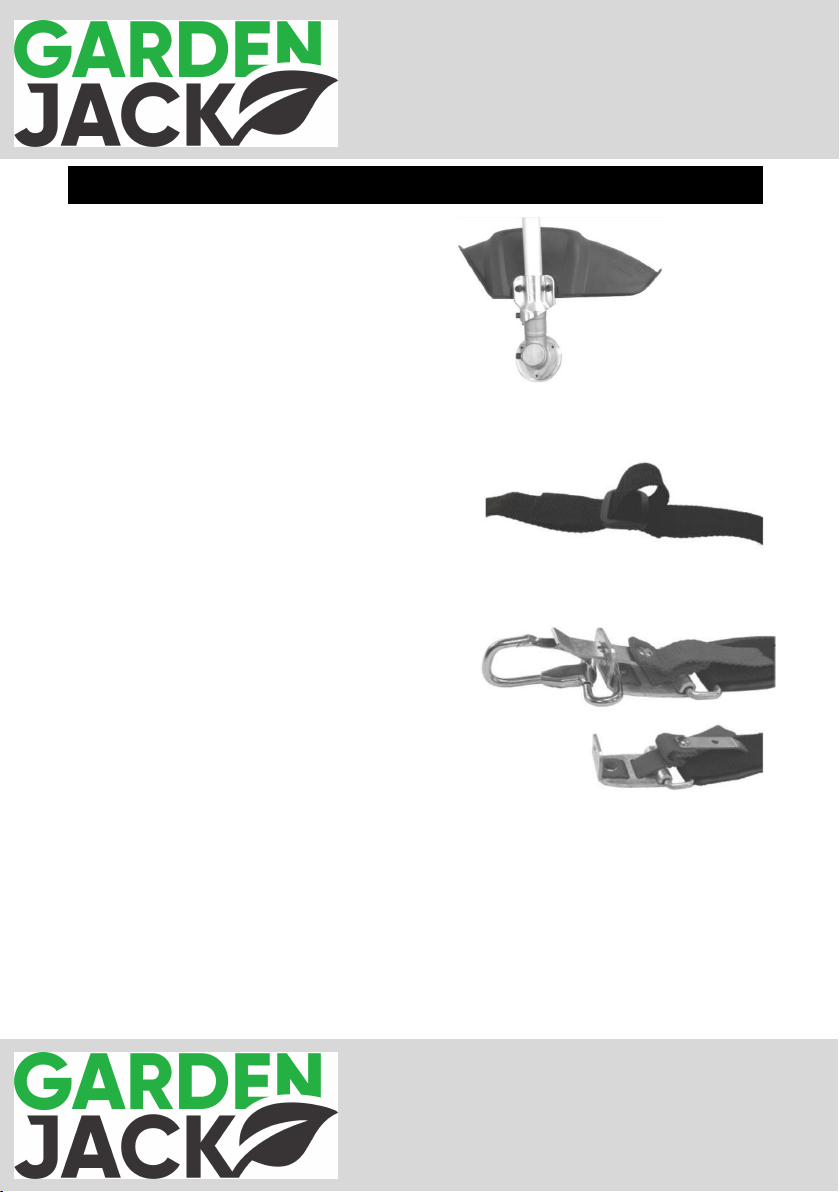

Using the Shoulder Strap

The machine has to be operated with a suitable shoulder strap.

1. Hook the machine on the carabiner

hook and allow the machine to

balance on the shoulder strap. By

doing this, the machine must be

switched off.

2. For better stability, thread the end of

the strap over the buckle, as shown

in the picture. Tighten the end.

This will prevent the strap from

slipping out of the buckle due to the

weight of the device.

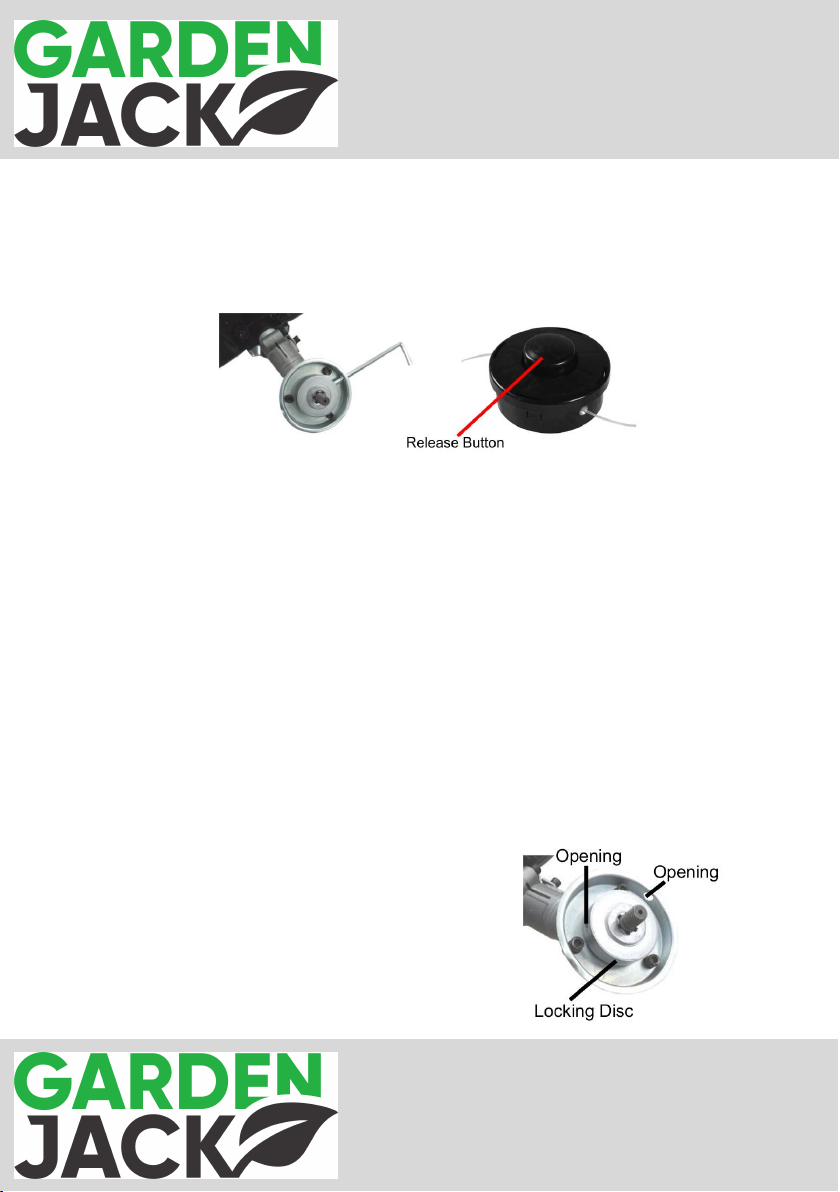

3. Slide the pin into the opening. Thus,

the carabiner hook is securely

fastened.

4. Pull out the pin to remove the carabiner hook.

·Always switch off the machine before removing the carabiner hook from

the shoulder strap.

·Hang the machine on the carabiner hook. The cutting tool must evenly

touch the ground when working in comfortable working position. If

necessary, loosen the suspension eye (10) by using the hex key, move it

back or forth & re-position the suspension eye.